Panel Beam Saw

Panel Beam Saw.

BestIn panel beam saws are designed to meet the needs of small, medium, and large industries. It can offer high-precision cutting in shorter times with automated capabilities. And it is built to last, making them an excellent choice for any industry that values efficiency and quality.

Automatic Panel Beam Saw

BestIn panel beam saws use a high-precision cutting technique that allows for incredibly accurate cuts, even on large and heavy materials.

The CNC system is equipped with panel beam saws. It allows for high automation capabilities and makes the cutting process faster, more efficient, and less labor-intensive. With the use of specialized software, users can program the saw to make various cuts, including straight cuts, angles, and slopes, without the need for manual adjustment.

- CNC Operation

- Quickly And Efficiently Cutting Large Panels

- Maximum Automation

- Save Human Cost

Total Power | 28kw |

| Working Air Pressure | 0.6mpa |

Mini Size of Wook Piece (L*W) | 34*45mm | Max Size Of Wook Piece (L*W) | 3180*3180mm | |

Main Saw Power | 15kw | Scoring Saw Power | 1.5kw | |

Main Saw Blade Speed | 3800r/Min | Scorning Saw Blade Speed | 5300r/Min | |

Saw Carriage Power | 2kw | Saw Carriage Feed Speed (Max) | 120m/Min | |

Feed Servo Moto | 2kw | Cutting Speed (Max) | 95m/Min | |

Feed Speed (Max) | 95m/Min | Main Blade Inside& Outside Diameter | Φ400*Φ75mm | |

Scorning Blade Inside & Outside Diameter | Φ200*50mm | Maximum Cutting Thickness | 90mm | |

Air Consumption | 320L/Min | Vacuum Speed | 30m/S | |

Gross Weight | 6000KG | Package Size | 5600*1950*2200 |

Industrial Panel Beam Saw Feature

Advance Saw Carriage

Guarantees perfect and chip-free cutting results

Automatic Feeding

Speed up the cutting process and save human costs.

Strong Power

Strong power makes machine running steady.

CNC Control System

The "Quick-Set-System" enables you to make rapid adjustments to different materials.

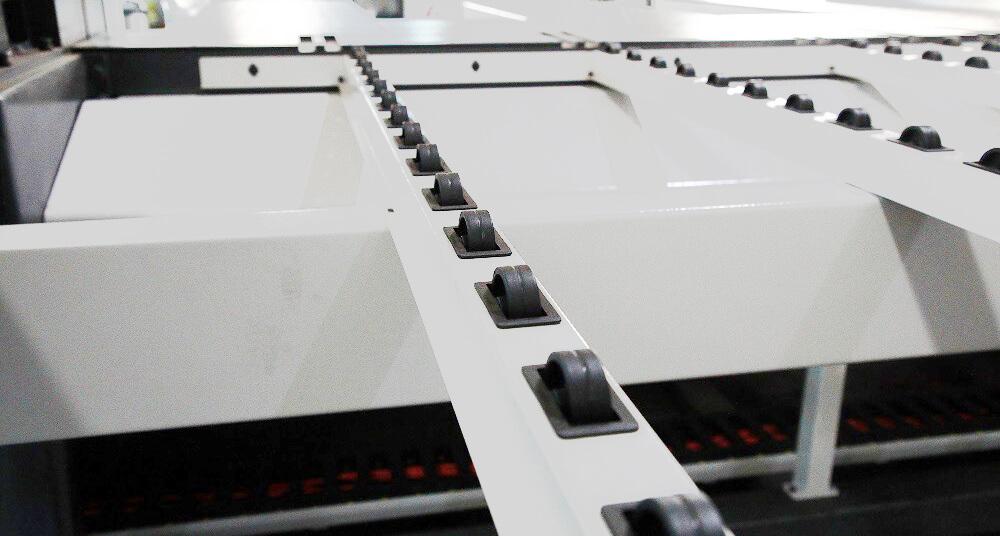

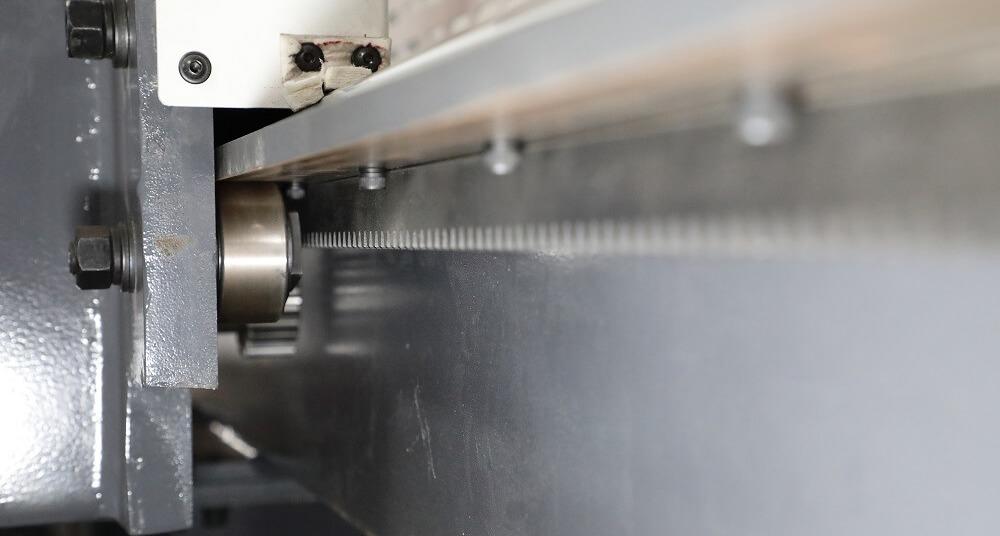

Saw Carriage Unit.

Saw carriage can slide along polished rollers with exceptional smoothness and accuracy.

To ensure even greater precision, the saw carriage’s height can be adjusted via linear guides.

Powerful Motor.

With their advanced technology and precision engineering, these motors can deliver a smooth and consistent cutting performance. It ensures every cut is made with the highest level of accuracy.

Whether they are working with thick hardwoods, dense laminates, or delicate veneers, this machine can handle it all with exceptional precision and efficiency.

Roller Track.

Thanks to its robust construction and high-quality materials, the roller track in the panel beam saw is able to support even the heaviest and most cumbersome panels with ease. This ensures that woodworkers can work with a wide range of materials, from small panels to large sheets, without any issues.

Air Flotation Table.

Air flotation table tops play a critical role in making material loading and unloading easier and more efficient.

This cushion of air reduces friction and allows the material to glide easily across the surface of the table.

Feeding Gripper.

The panel beam saw is equipped with pneumatic holding grippers. It utilizes a powerful system of pneumatic pressure to grip panels with precision and stability. This ensures that panels are held firmly in place during cutting, reducing the risk of errors or inaccuracies and improving the overall quality of the finished product.

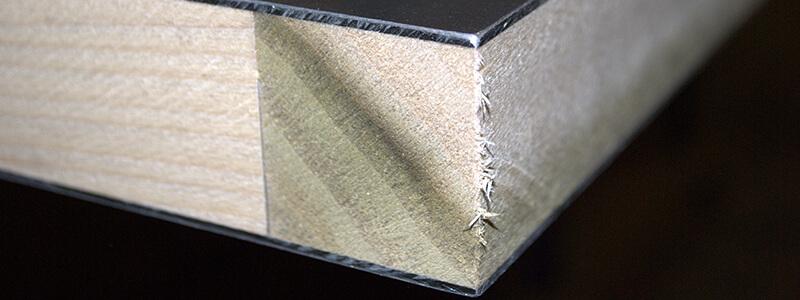

Panel Beam Saw Cutting Sample

Panel Beam Saws is a highly versatile woodworking machine that has been specifically designed to handle a wide range of materials, making it the ideal solution for medium and large-sized factories. With its advanced features and capabilities, it can cut solid wood boards, MDF boards, PVC boards, and even aluminum plywood with exceptional precision and accuracy.

Solid Wood Board

MDF Board

PVC Board

Aluminum Plywood Board

Panel Beam Saw for Different Industries

A horizontal panel beam saw is a type of woodworking machine that is specifically designed to cut panels horizontally. Here are some common applications of horizontal panel beam saws:

Furniture Manufacturing

Horizontal panel beam saws are ideal for cutting large panels, such as sheets of plywood, MDF, or particleboard, into smaller sizes. This makes them popular in the furniture manufacturing industry, where large panels need to be cut to size for various components.

Flooring Industry

Panel beam saw is used to produce flooring components, including laminate flooring, hardwood flooring, and engineered flooring. Its precision cutting capabilities ensure that the flooring components fit together seamlessly, creating a smooth and uniform surface.

Why Choose BestIn

We are a leading manufacturer of high-quality sliding table saws, dedicated to providing our customers with top-of-the-line products and excellent customer service. Our state-of-the-art manufacturing facilities include advanced machines such as CNC Milling Machines, Shot Blast Machines, Laser Machines, and Bending Machines. With these advanced manufacturing capabilities, we have the ability to produce precision-made saws that meet the needs of professionals in a wide range of industries.

The core components of our sliding table saws are supplied by a certified manufacturer that has been approved by SGS. This means that the supplier has undergone rigorous testing and certification processes to ensure that their products meet the highest standards of quality and performance. By using these certified components, we can ensure that our sliding table saws are stable, accurate, and reliable, providing our customers with the best possible performance.