Sliding Table Saw

Sliding Table Saw.

BestIn has been focusing on manufacturing Sliding Table Saw with professional knowledge and full of experience. Whether you are a craftsman, furniture manufacturer, or wooden board supplier, we will offer you a first-class and efficient sliding table saw.

Sliding Table Saw For Sale

Our Sliding Table Saw is the perfect solution for the precision cutting of sheet materials used in the production of kitchen cabinetry, furniture, and millwork operations, among other applications.

With a bigger sliding table made from a precision aluminum extrusion and running on precision linear guide rails, you can trust that every cut will be accurate and consistent.

Whether you are a professional woodworker or a hobbyist, our Sliding Table Saw is designed to meet your needs and exceed your expectations.

- Precise Cutting

- Straight And Angled Cutting

- Tilting Saw Blade 0-45°

- Custom Size for Saw Table

Best Sliding Sable Saw

We offer all kinds of sliding table saw to meet your specific requirements and different industry. We also support OEM and ODM to expand your brand and boost your woodworking machine business.

| Machine No. | BSTS32H |

| Sliding Table Size | 3200*425mm |

| Max. Cutting Length | 3200mm |

| Max. Cutting Width | 1300mm |

| Main Saw Diameter | 300mm (250-400mm) |

| Max. Cutting Height | 75mm |

| Main Saw Speed | 4000-6000rpm/Min |

| Main Saw Arbor Diameter | 30mm |

| Sawing Angle | 0-45˚ |

| Main Motor Power | 5.5kw |

| Scoring Saw Diameter | 120mm |

| Scoring Saw Speed | 7000-8000rpm/Min |

| Auxiliary Saw Diameter | 200mm |

| Auxiliary Motor Power | 1.1kw |

| Overall Dimension | 3200*3490*900mm |

| Machine No. | BSTS32 |

| Sliding Table Size | 3200*425mm |

| Max. Cutting Length | 3200mm |

| Max. Cutting Width | 1300mm |

| Main Saw Diameter | 300mm (250-400mm) |

| Max. Cutting Height | 75mm |

| Main Saw Speed | 4000-6000rpm/Min |

| Main Saw Arbor Diameter | 30mm |

| Sawing Angle | 0-45˚ |

| Main Motor Power | 5.5kw |

| Scoring Saw Diameter | 120mm |

| Scoring Saw Speed | 7000-8000rpm/Min |

| Auxiliary Saw Diameter | 200mm |

| Auxiliary Motor Power | 1.1kw |

| Overall Dimension | 3200*3490*900mm |

| Machine No. | BSTS32B |

| Sliding Table Size | 3200*425mm |

| Max. Cutting Length | 3200mm |

| Max. Cutting Width | 1300mm |

| Main Saw Diameter | 300mm (250-400mm) |

| Max. Cutting Height | 75mm |

| Main Saw Speed | 4000-6000rpm/Min |

| Main Saw Arbor Diameter | 30mm |

| Sawing Angle | 0-45˚ |

| Main Motor Power | 5.5kw |

| Scoring Saw Diameter | 120mm |

| Scoring Saw Speed | 7000-8000rpm/Min |

| Auxiliary Saw Diameter | 200mm |

| Auxiliary Motor Power | 1.1kw |

| Overall Dimension | 3200*3490*900mm |

| Machine No. | BSTS32N |

| Sliding Table Size | 3200*425mm |

| Max. Cutting Length | 3200mm |

| Max. Cutting Width | 1300mm |

| Main Saw Diameter | 300mm (250-400mm) |

| Max. Cutting Height | 75mm |

| Main Saw Speed | 4000-6000rpm/Min |

| Main Saw Arbor Diameter | 30mm |

| Sawing Angle | 0-45˚ |

| Main Motor Power | 5.5kw |

| Scoring Saw Diameter | 120mm |

| Scoring Saw Speed | 7000-8000rpm/Min |

| Auxiliary Saw Diameter | 200mm |

| Auxiliary Motor Power | 1.1kw |

| Overall Dimension | 3200*3490*900mm |

Sliding Table Saw Feature

Strong Power

Strong power makes machine running steady.

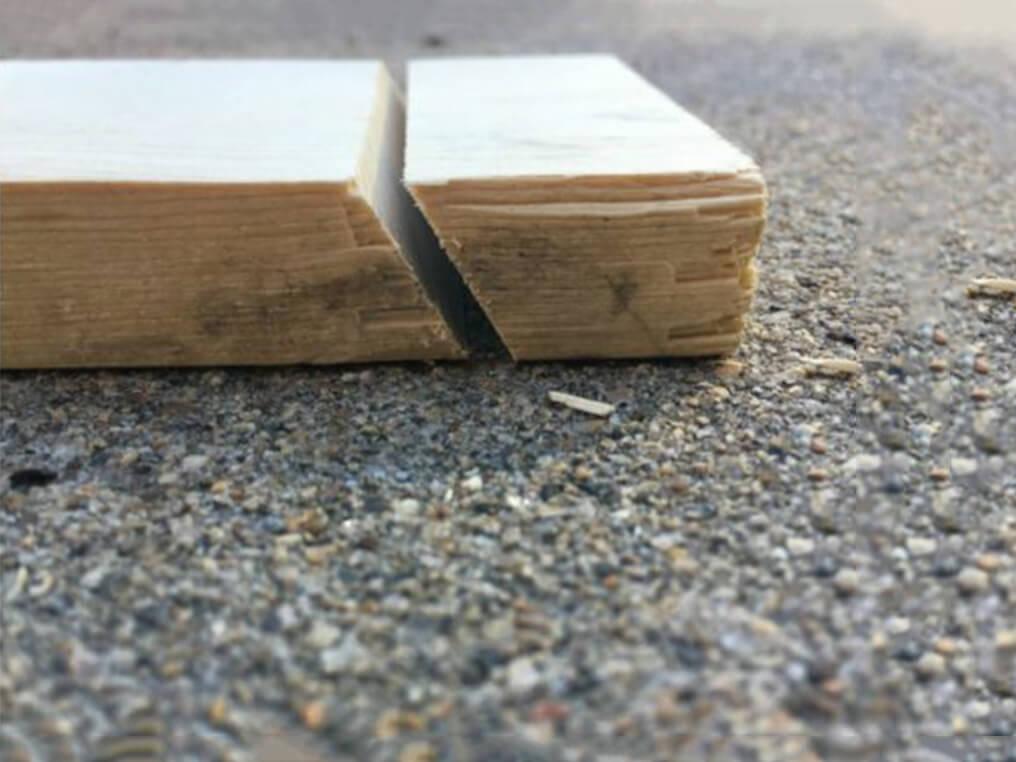

Double Blade

Double blade makes cutting more precisely and quickly.

Extended Table

Etendend table can be suite for multiple wook piece.

Easy Operation

Humanized control panel makes operation easily.

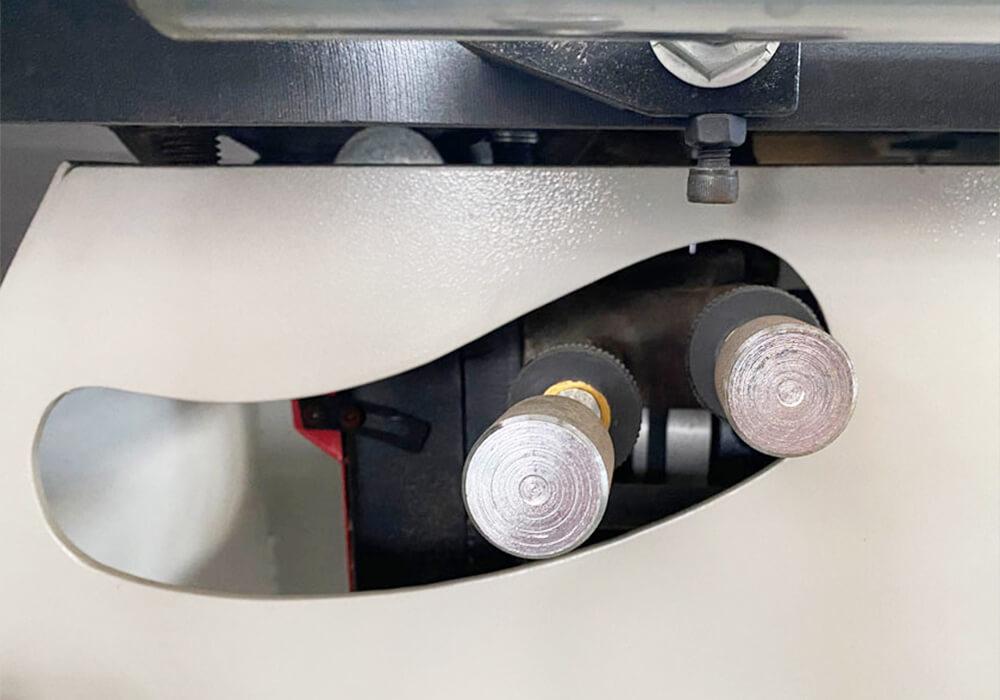

Saw Unit.

Blade group was angled from 0 to 45.5 degrees and constructed entirely from cast iron, featuring a deep structure to accommodate large diameter blades up to 550 mm and enhance the collection of sawdust.

In order to ensure a strong connection, the act of raising the blade shaft is installed on linear guides and recirculating ball bearings. Additionally, the blade shaft bearings are positioned far apart from each other, which helps to enhance accuracy and reduce vibrations on the circular saw. This design is also ideal for environments with a lot of dust, as it helps to extend blade life.

Sliding Table.

With precision-hardened upper and lower linear guide rails, the sliding table glides effortlessly. The combination of chrome rollers and hardened rails makes them incredibly durable against wear and tear.

The table can be locked securely in various positions, making it easier to load every panel. Furthermore, a return handle is included to effortlessly restore the table to its original position.

Rip Fence.

By using the single-handed adjustment system, the rip fence can be quickly and accurately adjusted along a linear guide rail. To enable tight bevel cuts, the operator can position the aluminum fence as desired and set it flat.

Cross-cut Fence.

The crosscut fence can be adjusted easy and able to help saving times.

Thanks to the telescopic crosscut fence, you can perform cross-cuts up to 3200 mm with ease. The fence is equipped with an ergonomic scale and readout on the stops, ensuring precise setup every time. Additionally, the fence can tilt from 90° to 45°, with a fixed-end stop position ensuring a perfect 90° position.

When it comes to making precise adjustments, the miter scale and magnifying glass on the fence stop are essential features. Readable from the operating area, these tools allow for unparalleled accuracy in your woodworking projects.

CE Safety Guard.

Safety Guard on blade is also top-notch, with a built-in dust extraction port to keep your workspace clean and safe. The quick-change guard system allows you to choose between the straight guard and bubble guard for bevel cutting, providing you with maximum flexibility.

One of the most impressive features of our sliding table saw is the hinged arm on the overarm blade guard. This innovative design allows you to move the guard out of the way easily, making servicing the machine or blades a breeze.

Sliding Table Saw Cutting Type

Sliding table saws are also commonly used for rip cuts, cross cuts, and bevel cuts. This makes them an essential tool in many woodworking shops, as they can handle a wide range of cutting tasks with ease.

Rip Cutting

Cross Cutting

Bevel Cutting

Miter Cutting

Sliding Table Saw for Different Industries

Precision sliding table saws are powerful and versatile woodworking tools that offer exceptional precision and accuracy when cutting wood or other sheet materials. Here are some industries where precision sliding table saws are commonly used:

Woodworking Industry

Sliding table saws are widely used in the woodworking industry for cutting large panels of wood into precise dimensions. They are particularly useful in cabinet making, furniture making, and other fine woodworking projects where precision and accuracy are essential.

Metalworking Industry

Panel table saws can also be used in the metalworking industry for cutting thin sheets of metal. With the right blade, they can cut materials like aluminum and thin sheets of steel. Metalworking shops often use panel table saws for cutting metal stock to precise dimensions for use in various projects.

Plastic Industry

Precise sliding table saws can also be used in the plastic industry for cutting various types of plastic materials. This includes materials like acrylic, polycarbonate, and PVC. Panel table saws can cut these materials with precision, making them an essential tool in the manufacturing of plastic products.

Sign-making Industry

Precision sliding table saws are commonly used in the sign-making industry for cutting large panels of materials like aluminum composite panels, PVC, and other sign-making materials. With the ability to cut these materials with precision, precision sliding table saws are an essential tool in the production of high-quality signs and graphics.

Why Choose BestIn

We are a leading manufacturer of high-quality sliding table saws, dedicated to providing our customers with top-of-the-line products and excellent customer service. Our state-of-the-art manufacturing facilities include advanced machines such as CNC Milling Machines, Shot Blast Machines, Laser Machines, and Bending Machines. With these advanced manufacturing capabilities, we have the ability to produce precision-made saws that meet the needs of professionals in a wide range of industries.

The core components of our sliding table saws are supplied by a certified manufacturer that has been approved by SGS. This means that the supplier has undergone rigorous testing and certification processes to ensure that their products meet the highest standards of quality and performance. By using these certified components, we can ensure that our sliding table saws are stable, accurate, and reliable, providing our customers with the best possible performance.

Related Woodworking Machine

Fold Table Saw

- Easy to Fold

- Portable to Carry