Struggling with inaccurate cuts, unwieldy sheet goods, or safety risks on a standard table saw? A sliding table saw attachment could be your solution.

These innovative table saw accessories transform your setup into a precision woodworking tool, rivaling the accuracy and repeatable cuts of European sliding table saws without the high cost or space demands.

In this article, we’ve tested the top sliding table saw attachments to find the best sliding table saw attachment, delivering insights for hobbyists, professionals, and workshop owners alike.

Table of Contents

1. Types of Sliding Table Saw Attachments

1.1. Crosscut Sled

Crosscut Sled consists of a sturdy wooden or plastic base, a fence to guide the wood, and runners that fit into the miter slots on the saw’s table. The sled is designed to be pushed through the blade of the saw, allowing for straight, square, and accurate cuts every time. Using a crosscut sled has several benefits.

Firstly, it ensures safety. The sled provides stability and prevents the wood from moving during cutting, minimizing the risk of accidents.

Secondly, it enhances accuracy. The sled’s fence ensures that each cut is square, and the runners keep the sled aligned with the blade, reducing the possibility of mistakes.

Lastly, it allows for repeatable cuts. Once you set the sled up, you can make the same cut over and over again with consistent results.

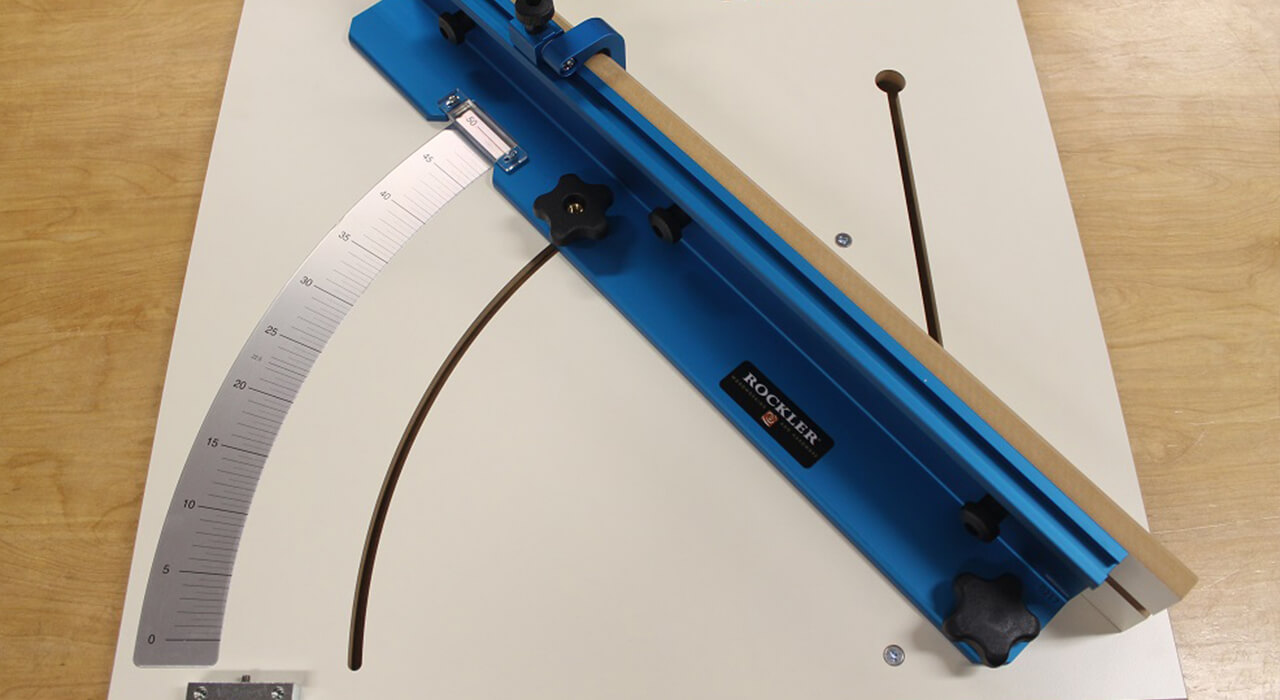

1.2. Miter Gauge

Miter Gauge is an essential tool for any woodworking enthusiast. It is a device that helps you make precise angle cuts on a piece of wood.

The miter gauge consists of a guide bar, a locking mechanism, and a rotating scale. It is designed to fit into the miter slot on a table saw, ensuring accurate cuts.

When you need to make an angled cut, you adjust the miter gauge to the desired angle by unlocking the locking mechanism, rotating the gauge to the desired angle, and then locking it back in place. The rotating scale helps you accurately set the angle you need.

Once set, you can then use the miter gauge to guide your wood through the saw blade, ensuring a precise and accurate cut.

It allows you to make repeat cuts with ease. You can set the gauge to the desired angle, and then make the same cut over and over again. This is particularly useful when making frames, as you can ensure that each piece is cut to the same angle.

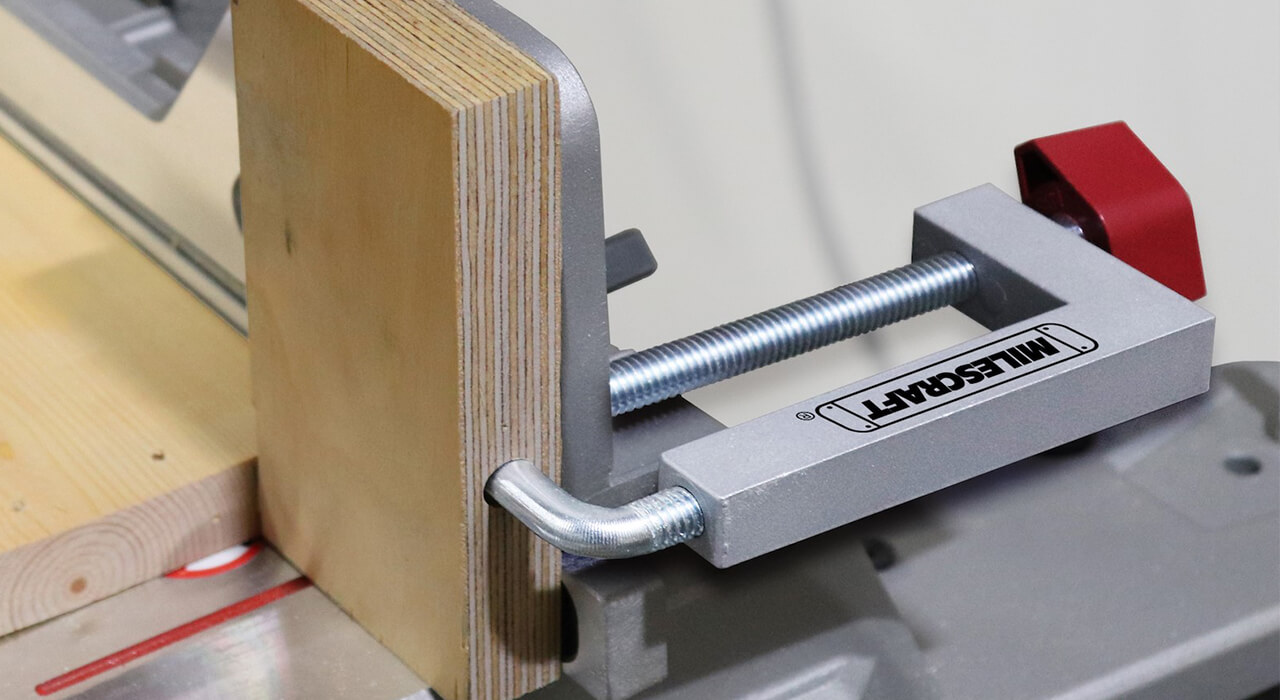

1.3. Tenoning Jig

Tenoning Jig is a versatile and useful tool for any woodworking enthusiast. It is designed to help you make precise and accurate tenon cuts on wood.

Tenoning jig consists of a base, a fence, and a clamp to hold the wood in place. It is designed to be used with a sliding table saw attachment. The Tenoning Jig guides the wood through the saw blade, ensuring a straight and accurate cut. Using a tenoning jig has several benefits.

Firstly, it ensures safety. The jig provides stability and prevents the wood from moving during cutting, minimizing the risk of accidents.

Secondly, it enhances accuracy. The jig’s fence ensures that each cut is straight, and the clamp keeps the wood firmly in place, reducing the possibility of mistakes.

Lastly, it allows for repeatable cuts. Once you set the jig up, you can make the same cut repeatedly with consistent results.

1.4. Fence Clamp

Fence Clamp is an essential tool for any woodworker who uses a sliding table saw attachment. It is used to secure a wooden fence to the table saws sliding table, ensuring a straight and accurate cut every time.

1.5. Digital Reader

Digital

Reader is a device that allows for precise

measurement and tracking of measurements in various industries.

2. Are Sliding Table Saw Attachments Worth The Investment?

When it comes to woodworking, Sliding Table Saw Attachment can make all the difference. But with the increase in cost, the question arises: are these attachments worth the investment?

First and foremost, sliding table saw attachments offer a significant advantage in terms of precision and efficiency. These attachments allow for smoother and more accurate cuts, which can save time and improve the overall quality of your work.

Additionally, they reduce the risk of kickback, which is a common safety hazard when working with table saws.

However, it’s important to consider the extra cost that comes with investing in a sliding table saw attachment. These attachments can be expensive.

They also require some additional maintenance and adjustment to keep them in optimal working condition. If precision and efficiency are important to you, then a sliding table saw attachment can be a wise investment.

However, if you are on a tight budget, you may need to carefully weigh the pros and cons before making a decision.

3. Top Sliding Table Attachment Brands

Choosing the right sliding table attachment means comparing features, build quality, and compatibility. Here are some of the top-rated brands and models used in cabinetry shops:

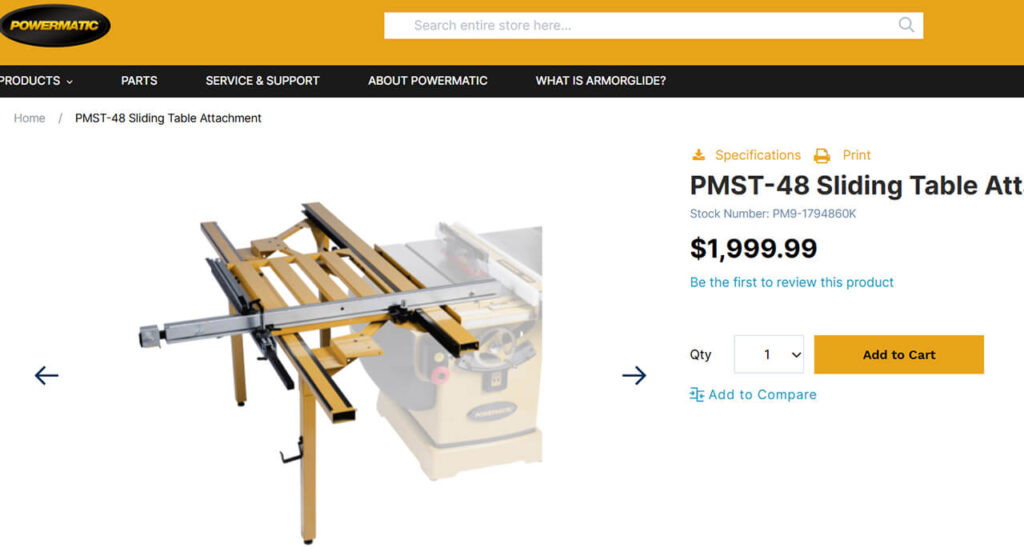

3.1. Powermatic PMST-48 Sliding Table

Powermatic PMST-48 Sliding Table features a steel frame, precision bearing rails, and a large 62½″ travel. The extruded aluminum crosscut fence slides easily for angles, and quick-lock handles make adjustments a breeze.

Powermatic emphasizes that this attachment enables smooth and precise cuts on large sheets and stock. And it is engineered to ensure precision while maximizing efficiency.

- Pricing: About $1,900.

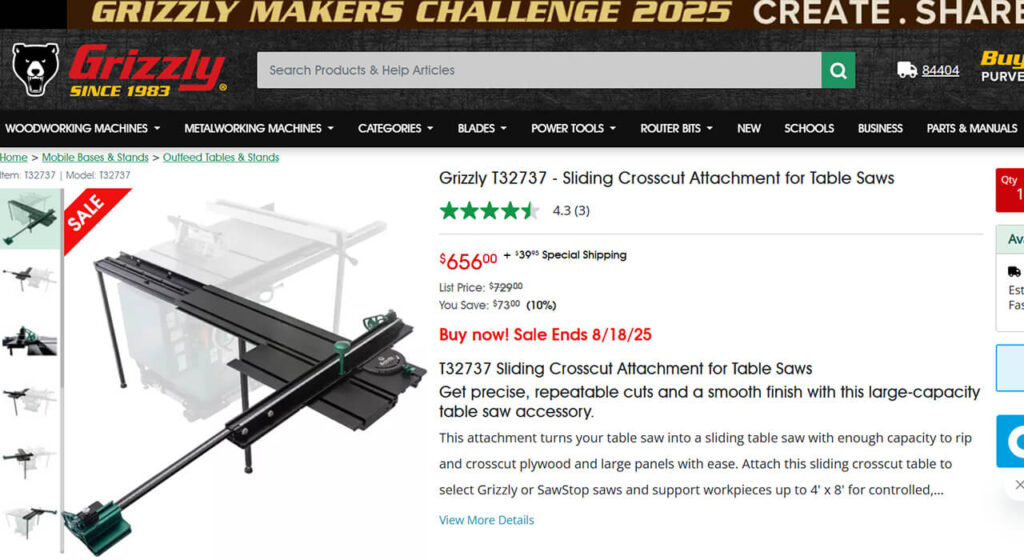

3.2. Grizzly T32737 Sliding Crosscut Table

Grizzly T32737 Sliding Crosscut Table anodized aluminum table supports workpieces up to 4′×8′. The fence has built-in stops for common angles, and two flip stops allow quick repeat cuts.

A telescoping extension bar and collapsible legs give extra support for large panels. Built with low-friction aluminum and sealed bushings, it offers professional results on a budget.

- Pricing: Around $650.

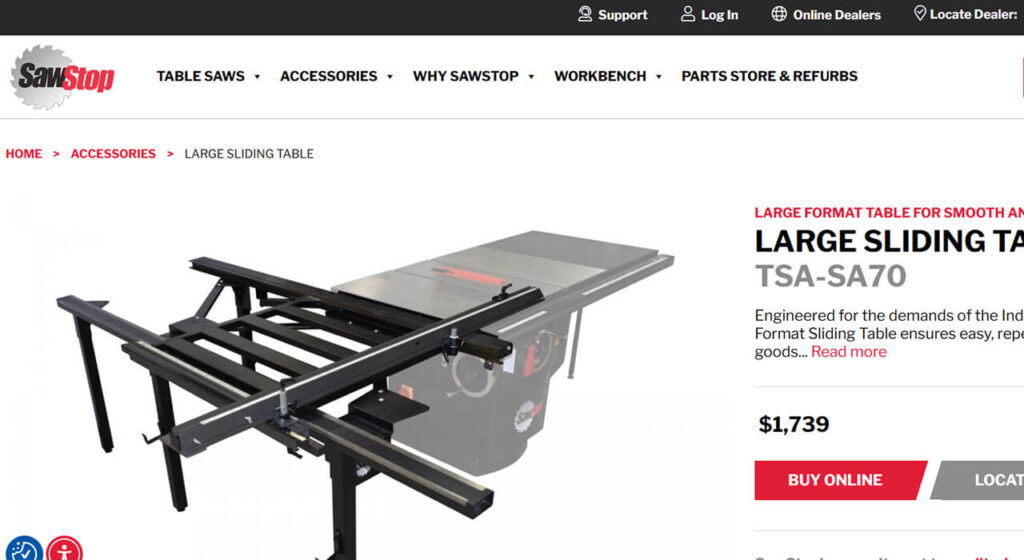

3.3. SawStop Large Sliding Table (TSA-SA70)

SawStop Large Sliding Table (TSA-SA70) has a 30″×30″ rugged steel table and 14 sealed ball bearings for a silky smooth glide. With six mounting options (traditional or Euro style) and an adjustable fence, it handles sheets up to 70″ long. Detent stops at 0°-45° and a flip-stop make angled cuts quick and precise. SawStop highlights its rigid steel frame and heavy-duty design to ensure maximum reliability under load.

- Pricing: About $1,740.

4. Can I Use Sliding Table Saw Attachments With Any Type Of Saw?

Sliding Table Saw Attachments are designed to work with specific types of saws. And not all saws are compatible with these attachments.

Before purchasing a Sliding Table Saw Attachment, it’s important to check the Compatibility with your saw.

Most sliding table saw attachments are designed to work with Cabinet Table Saws, which have a larger table and a more powerful motor.

Some sliding table saw attachments are also compatible with contractor table saws, which are smaller and less powerful than cabinet table saws.

It’s important to note that not all sliding table saw attachments will fit all types of saws, so it’s important to do your research before making a purchase.

5. How Do I Maintain My Sliding Table Saw Attachment?

It is essential to maintain your sliding table saw attachment to ensure its longevity and optimal performance.

Here are some tips on how to properly maintain your sliding table saw attachment:

- Clean It Regularly: It is important to clean your sliding table saw attachment after each use. Wipe it down with a dry cloth or use compressed air to remove any sawdust or debris that may have accumulated.

- Lubricate Moving Parts: Lubricate the moving parts of your sliding table saw attachment periodically to ensure smooth operation. Use a silicone or graphite lubricant, as oil-based lubricants can attract sawdust.

- Check For Wear And Tear: Inspect your sliding table saw attachment regularly for any signs of wear and tear. Replace any damaged or worn-out parts as soon as possible.

- Keep It Covered: When not in use, cover your sliding table saw attachment with a dust cover to protect it from moisture and dust.

- Store It Properly: Store your sliding table saw attachment in a dry and dust-free area.

Avoid stacking heavy objects on top of it, as this can damage the attachment.

By following these maintenance tips, you can ensure that your sliding table saw attachment will provide you with many years of reliable service.

6. Can I Use Sliding Table Saw Attachments For Angled Cuts?

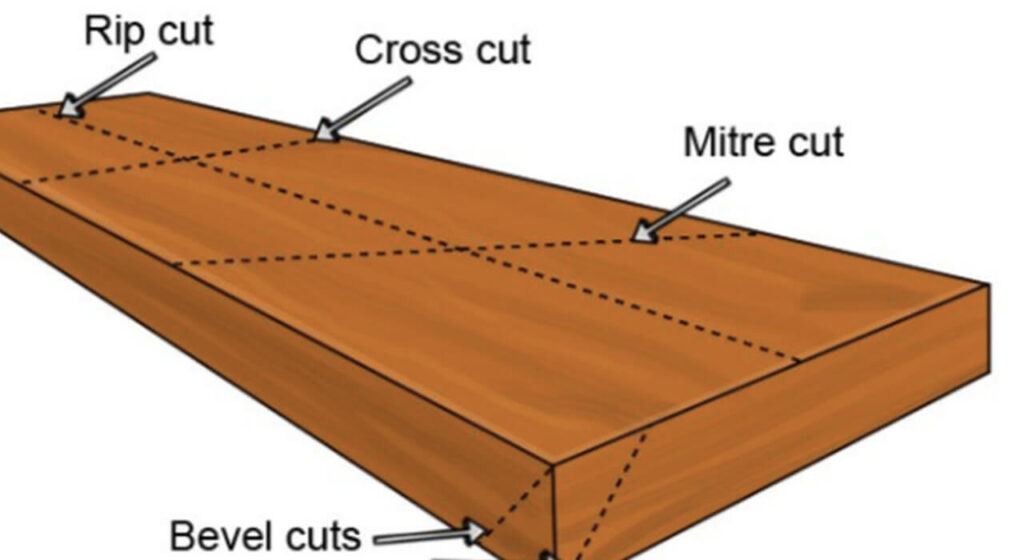

When it comes to angled cuts, sliding table saw attachments can be especially useful. The sliding table allows for the wood to be held securely in place while the blade cuts at the desired angle. This ensures that the cut is both accurate and safe.

However, it’s important to note that not all sliding table saw attachments are designed for angled cuts.

Some may only allow for straight cuts, so it’s important to check the specifications of the attachment before purchasing.

7. Choosing and Buying a Sliding Table Attachment

When selecting a sliding table, keep these guidelines in mind:

-

Fit and Compatibility: Verify that the attachment works with your saw’s make and model. Note the required saw table size and blade tilt (left or right). Some tables have adjustable brackets for various machines.

-

Capacity Needs: Determine the size of panels you cut most often. If you work with full sheets or large door panels, choose a table with a long travel (60″–70″ crosscut capacity). For mostly smaller cabinet parts, a compact crosscut table (30″–48″) may suffice.

-

Build Quality: Look for a sturdy frame (steel or cast aluminum) and precision rails. Sealed ball bearings or rollers will ensure long-term smooth operation. Anodized or powder-coated surfaces resist wear.

-

Fence and Features: A good sliding table has an adjustable fence that locks securely. Angle detents or stops (15°, 22.5°, 45°, etc.) make miter cuts easy. Extras like flip stops, fence storage hooks, and support legs add convenience.

-

Installation Support: Check if setup instructions are provided and if dealer support is available. Some suppliers offer installation services or videos. Since this is a big investment, reliable technical support is valuable.

-

Budget: Balance price with features. A cheaper model might suffice for occasional use, but serious production shops often benefit from higher-end units that maintain accuracy under heavy use.

Pro Tip: Visit dealers or woodworking shows to see tables in action. If possible, test cutting a panel with your saw. This hands-on comparison can reveal which system feels most solid and intuitive for your needs.

8. To Sum Up

Overall, choosing the best Sliding Table Saw Attachment comes down to personal preference and the specific needs of your woodworking projects.

It can take your woodworking to the next level by investing in a high-quality sliding table saw attachment.