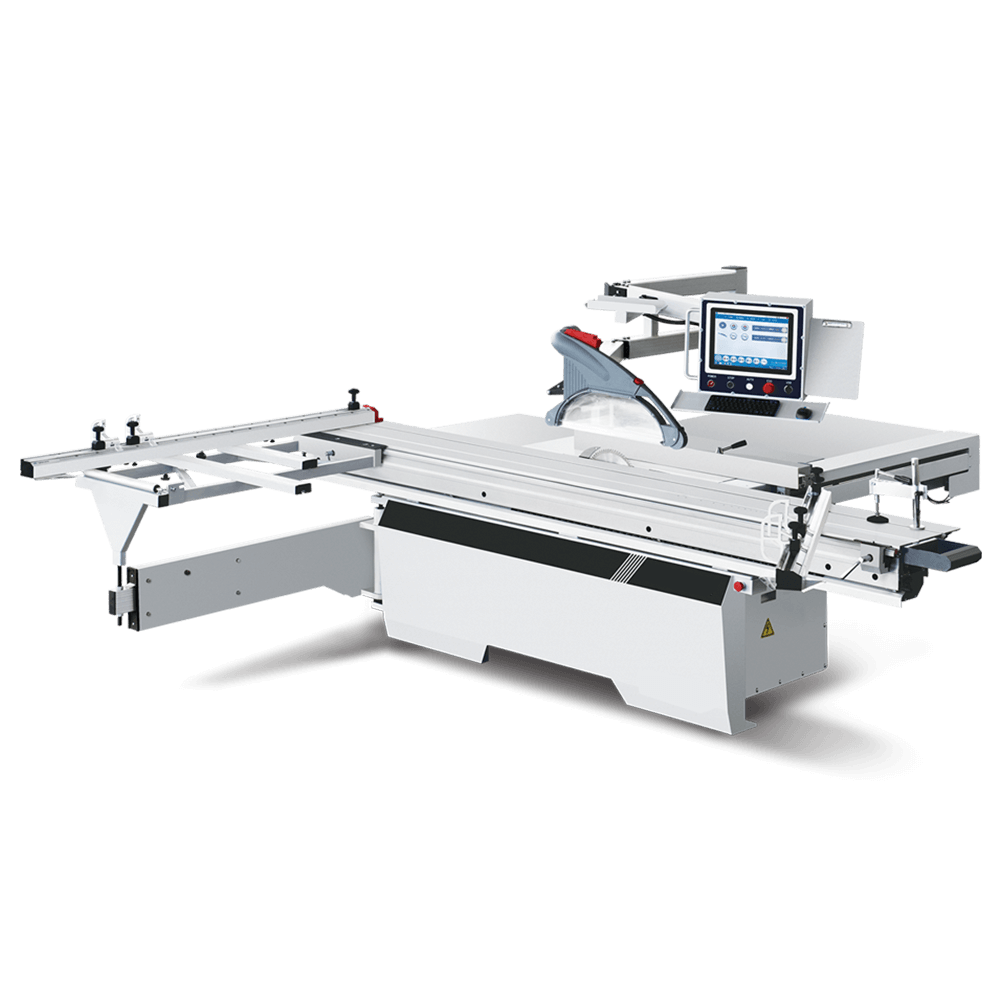

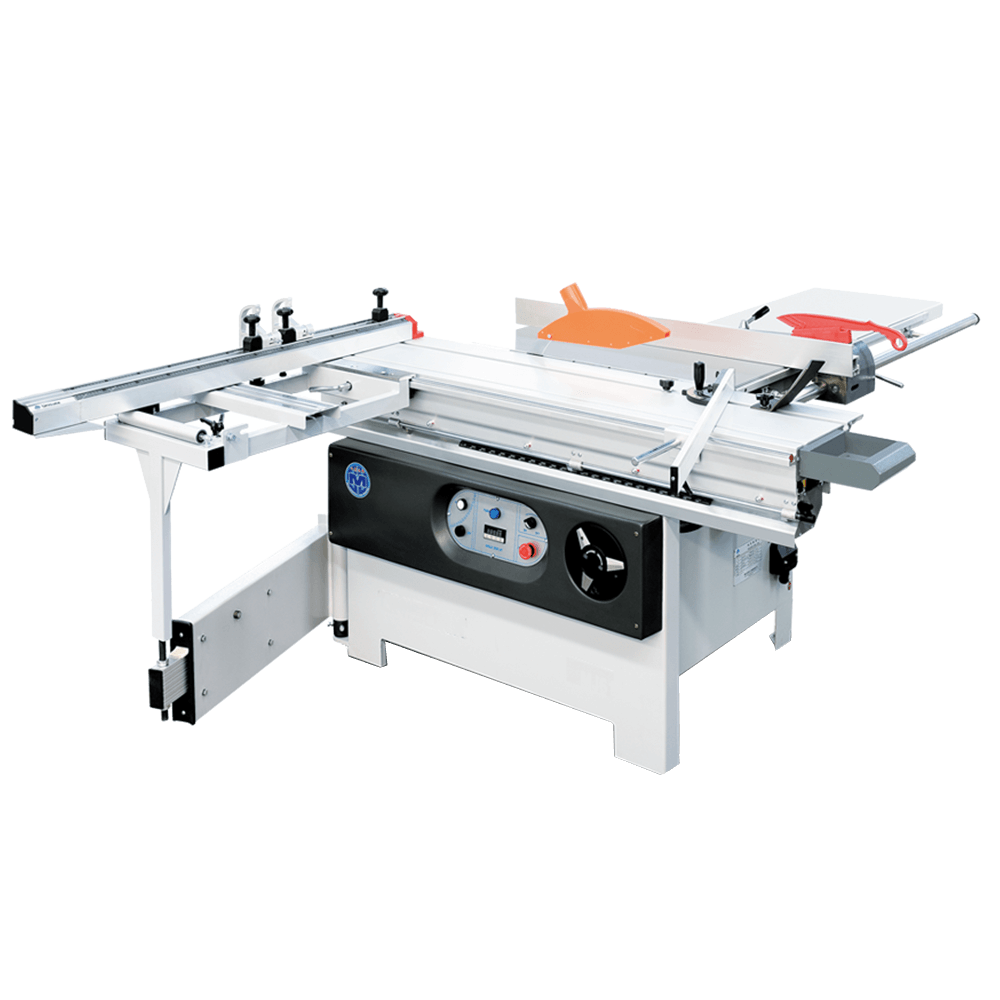

CNC Sliding Table Saw

CNC Sliding Table Saw

Our CNC Sliding Table Saw is perfect for woodworkers who need precision and efficiency in their projects. With programmable settings and a large cutting capacity, it allows you to streamline your workflow while maintaining accuracy.

Benefits

- High Efficiency

Store your cut programs, reducing setup time and ensuring

repeatable results across shifts.

- One-Person Operation

The large sliding table allows one operator to handle

panels up to 10 feet long, saving labor costs.

- Versatile Cutting

Program and save multiple cutting applications for

different projects, increasing your workshop’s flexibility.

- Precision Cuts

Achieve accurate cuts with the CNC system, reducing waste

and ensuring high-quality finishes.

- Durable Design

Built with industrial-grade materials for long-lasting

performance in any production environment.

- Time-saving

With automated adjustments and smooth sliding table

movement, it makes you working fast and efficiently.

Picture

Features

- CNC Control System

Equipped with a PC touchscreen panel with multiple-program memory, making you store cut programs for consistent results.

- Automated Adjustments

Program cutting width, blade tilt, and height for both the main and scoring saw blades, ensuring precise cuts every time.

- Rip Fence Automation

The servo motor moves the rip fence automatically based on your programmed settings for faster and easier adjustments.

- Sliding Table

The 3800 x 435 mm anodized aluminum sliding table glides effortlessly on precision shafts, making it easy to handle large panels.

- Heavy-Duty Frame

The cast iron frame and steel base reduce vibrations, providing stability for accurate, clean cuts.

- Powerful Motors

The 5.5kw main motor delivers constant speed and power, while the 0.75kw scoring motor ensures a crisp finish without extra sanding.

- Dust Collection System

A 100mm dust port keeps your workspace clean by easily connecting to an extraction system.

Technical Data

|

Dimension Of Sliding Table |

3200 × 435mm |

|

Gross Cut Capacity |

3200mm |

|

Wide Of Cut Between Saw Blade And Rip

Fence |

1300mm |

|

Saw Blade Diameter |

φ300mm(φ250-φ400) |

|

Height Of Cut 300Mm |

80mm |

|

Height Of Cut With Saw Blade 300mm At 45° |

55mm |

|

Speed Of Main Saw Spindle |

3000/4000/5000rpm |

|

Main Spindle Diameter |

φ30mm |

|

Tilting Saw Blade |

0-45° |

|

Main Motor |

5.5kw |

|

Scoring Saw Blade Diameter |

120mm |

|

Speeg Of Scoring Saw Blade |

8000r/min |

|

Scoring Spindle Diameter |

φ20mm |

|

Scoring Motor |

0.75kw |

|

Net Weight |

1080kg |

|

Overall Dimensions |

3350×3600×900mm |

Video& Brochures

We Are Here For You!

- +86 166 7861 1290

- Info@bestingroup.com

- www.bestingroup.com