Industrial Sanding Machines are powerful machines that automate the wood-finishing process. Unlike hand sanding, an industrial sander applies constant pressure and speed to smooth and level wooden surfaces.

These machines range from compact belt or disc sanders to large, wide-belt and drum sanders. They are engineered for heavy-duty use in factories and workshops. This guide will help you find a good Industrial Sanding Machine for Wood.

Featured Resource

Table of Contents

1. What Is an Industrial Sanding Machine?

An industrial sanding machine is essentially a heavy-duty sander designed for large-scale wood processing. It uses abrasive materials (belts, discs, drums, etc.) powered by electric motors to strip material and smooth surfaces.

Wood Sanding Machine automates the sanding process, providing consistent pressure and motion that manual sanding can’t match.

It can remove burrs, dust and paint quickly and evenly on wood board surface, creating a smooth, uniform surface ideal for staining or finishing. For example, a wide belt sander is commonly used to sand rough material until it reaches a desired thickness and/or is sufficiently conditioned for coating.

These machines use a conveyor and a broad abrasive belt to rapidly level huge panels.

In short, an industrial wood sanding machine is a robust, high-capacity tool that makes batch sanding fast, reliable, and precise.

2. Benefits of Industrial Sanding Machines for Wood

Industrial sanding machines deliver fast, consistent, high-quality finishes that save time and money.

They remove material quickly, drastically cutting processing time.

- Speed and Productivity: Industrial sanders obliterate roughness in seconds. A wide belt sander can produce a perfectly flat surface in less time than you could with a handheld sander, speeding up production schedules.

- Uniform Quality: By stabilizing feed speed and pressure, these machines create a uniform finish. The result is a smooth, blemish-free wood surface every time.

- Enhanced Surface Preparation: Precision sanding prepares wood perfectly for finishing. Sanding machines remove scratches, dents, and waves, allowing stains and coatings to be applied evenly.

3. Types of Industrial Sanding Machines

There are several main types of industrial wood sanders, each suited to different tasks. The four key categories are Belt Sanders, Drum Sanders, Brush Sander and Edge Sanders.

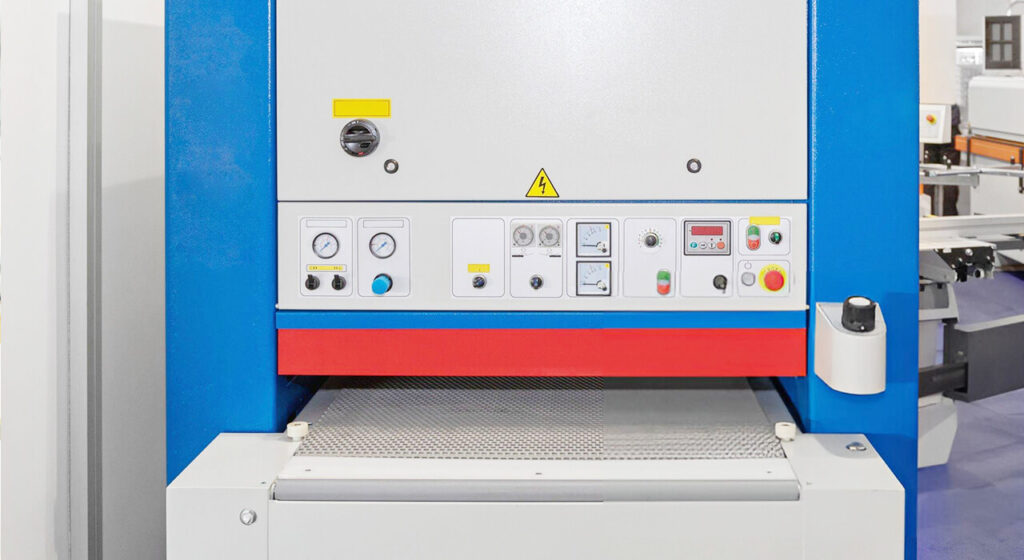

3.1. Wide Belt Sanders

Wide Belt Sanders are the workhorses of large-scale woodworking shops. They use a large, continuous abrasive belt—often 24 inches wide or more—to sand panels, doors, tabletops, and other broad surfaces.

How It Works:

- Wood pieces move through on a conveyor belt.

- The abrasive belt spins between two large drums.

- Adjustable pressure rollers press the belt onto the workpiece.

- Operators set feed speed and belt grit to control material removal.

Best For:

- High-volume production of cabinet panels, furniture tops, and flooring.

- Rough lumber dimensioning and fine finishing in one continuous pass.

- Applications where perfect flatness and uniform thickness are mandatory.

Key Advantages:

- Ultra-fast material removal. Large belts remove heavy stock quickly.

- Consistent finish. Automated feed and pressure rollers eliminate “sanding waves” from manual processes.

- Adjustable calibration. Multiple sanding heads allow coarse and fine sanding in a single pass.

- High throughput. Ideal for shops that need to process hundreds of boards per hour.

Considerations:

- Floor space: Requires a substantial footprint.

- Power requirements: Often 10–30 HP motors (or more) demand robust electrical service.

- Dust collection: High-volume dust output must be managed with a powerful dust-extraction system.

- Initial cost: Higher than smaller sanders, but ROI is rapid if you run large batches daily.

Power Tip: Invest in a model with a variable-speed conveyor and adjustable pressure. This flexibility lets you switch quickly between rough and finish sanding without changing machines.

3.2. Drum Sander

Drum Sanders use a large, rotating drum wrapped with sanding paper. Unlike wide belt sanders, they typically have a narrower belt but still handle wide boards—up to 30 inches or more, depending on the model.

How It Works:

- The workpiece feeds under a rotating drum that spins at a constant RPM.

- Sanding paper wraps around the drum, removing material as it rotates.

- Operators adjust drum height to set the cut depth per pass.

Best For:

- Thicknessing rough lumber and glued-up boards.

- Achieving exact uniform thickness across panels.

- Shops that need a robust machine but don’t produce wide panels continuously.

Key Advantages:

- Uniform thickness control. Ensures board thickness is consistent from edge to edge.

- High stock removal. Effective on thick, rough boards—even hardwoods.

- Compact footprint. Smaller than wide belt sanders, easier to fit in medium-sized shops.

- Lower cost than wide belt units, making it a common choice for mid-sized operations.

Considerations:

- Single grit per pass. You may need multiple passes with different grits for a fine finish.

- Feed speed limitations. Slower than wide belt sanders when working on broad panels.

- Dust management. Like all sanders, generates significant dust—plan accordingly.

Quick Note: Some modern drum sanders offer dual drums or two-stage sanding, where one drum does rough sanding and the second does finish sanding in a single pass. This speeds up throughput and improves finish quality.

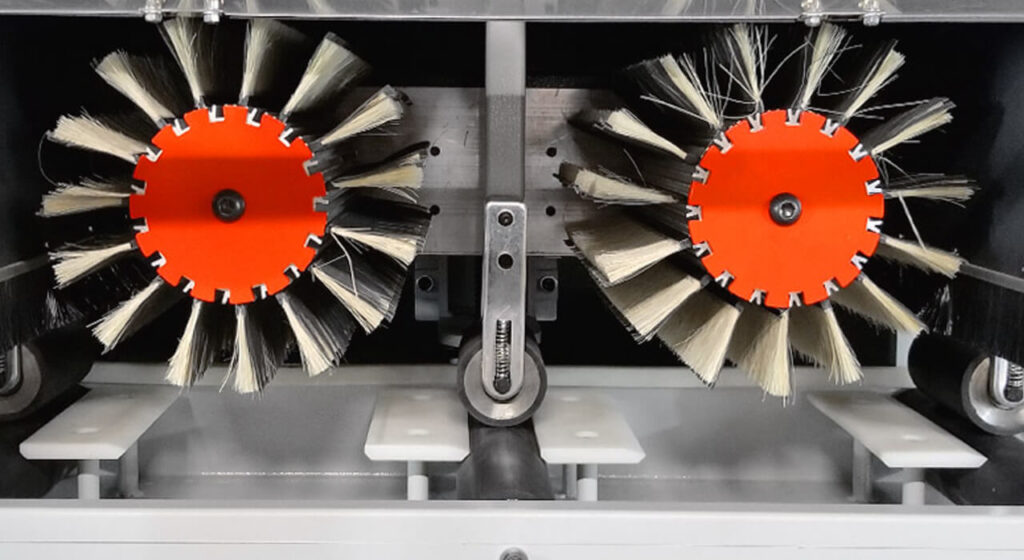

3.3. Brush Sander

Brush Sanders, also known as profile or contoured sanders, use rotating abrasive brushes instead of flat belts or discs. The flexible bristles conform to profiles, raised panels, and decorative mouldings.

How It Works:

- The workpiece moves under a series of spinning abrasive brush rolls.

- Brushes can be adjusted in height and angle to match the contours of the wood.

- Usually part of a production line where boards pass continuously under the brush heads.

Best For:

- Texturing surfaces (e.g., distressing, wire-brushing).

- Sanding intricate profiles on panels, doors, and MDF mouldings.

- Reaching into recessed areas and grooves where flat sanders cannot.

Key Advantages:

- Contour conformity. Brushes reach into nooks and crannies for uniform sanding on complex shapes.

- Delicate on veneers. Gentler than belts or discs—ideal for thin veneers or delicate species.

- Texturing options. Can create wire-brushed or reclaimed-wood looks.

- Mid-to-high production. More automation than hand-held tools, but often less aggressive than wide belt sanders.

Considerations:

- Less aggressive stock removal. Not designed for flattening or heavy sanding.

- Brush wear: Abrasive brushes wear faster than belts or discs—plan on replacing them regularly.

- Setup complexity: Adjusting brush height and angle takes time to dial in correctly for each profile.

Pro Insight: Combine a brush sander with a wide belt sander in your line. First, you can pre-sand flat surfaces on the wide belt; then, run the edges and profiles through the brush sander. This cuts finish time in half.

3.4. Edge Sander

Edge Sanding Machines are specialized machines designed to precisely sand the edges of panels, boards, cabinet doors, and tabletops. They remove mill marks, clean up edges after cutting, and prepare edges for finishing or assembly.

How It Works:

- The workpiece is guided along a fence so that only its edge contacts the sanding belt or pad.

- A vertically mounted belt or disc turns at high speed.

- Some models offer top and bottom sanding for both edges in a single pass.

- Adjustable fences and guides ensure consistent contact and uniform removal.

Best For:

- Removing mill marks and preparing edges before assembly.

- Cleaning up rough-cut edges from CNC routers or saws.

- Shops that require fast, repeatable edge finishes, such as cabinet and furniture manufacturers.

Key Advantages:

- Precision edge work. Achieve square, straight edges quickly and consistently.

- Consistent results. Adjustable fences keep edges uniform across multiple pieces.

- Time savings. Automated edge work is far faster than hand-sanding multiple edges.

- Versatile configurations. Models exist for both single-edge and dual-edge sanding, with options for different belt widths (1–4 inches).

Considerations:

- Limited to edges. Not suitable for face sanding or wide surfaces.

- Operator skill: While straightforward, achieving perfect squareness requires careful fence setup.

- Dust collection: Edges generate fine dust—ensure you have a hood or port to capture it before it clogs the belt.

Quick Tip: For cabinet shops, invest in a dual-edge sander that sands both the top and bottom edges in one pass. This cuts handling time and ensures both edges are squared identically.

4. Key Considerations When Buying One

Selecting the right Industrial Sanding Machine involves balancing technical specs, materials, and business goals. Keep these critical factors in mind:

-

Application and Material: What will you sand? Consider the thickness, width, and type of wood. Measure the largest pieces you’ll process. Make sure the machine’s maximum workpiece size and infeed height accommodate your materials. Also consider surface type – for example, rough lumber vs. veneered panels – as this affects roller choice and abrasive type.

-

Sanding Capacity: Look at belt or drum width and feed speed. A wider belt covers more area per pass; a faster conveyor speeds throughput. Match belt width to your board widths. Check whether you need multiple sanding stations (coarse and fine) or special attachments (like brush or fine polishing heads).

-

Motor Power and Speed: The machine’s horsepower dictates how quickly and aggressively it can sand. We suggest 5–30 HP for most wide-belt sanders, with larger plants using up to 30+ HP for very high throughput. If you frequently sand hardwoods or heavy stock, opt for a more powerful unit.

- Dust Collection: Sanding generates huge dust volumes. Choose a sander with a built-in dust collector or a strong dust-port. Some machines have integrated vacuum bags or ports for external collectors. Good dust removal is essential for worker safety and consistent results.

-

Safety Features: Industrial sanders should include emergency stops and guards. Robust safety features protect your operators and give you peace of mind.

-

Build Quality and Maintenance: Invest in a reputable brand. High-quality machines last longer and require fewer repairs. Look for features like durable cast-iron tables, precision bearings, and easy service access. Check warranty and support options.

-

Accessories and Consumables: Remember abrasives and replacement parts. Ensure you can source the right sanding belts, discs, and other accessories to keep your sander running. Using high-quality abrasives will maximize life and finish quality.

A quick checklist: 1) Size & Capacity: Belt width, table height, footprint. 2) Power: Motor HP and speed controls. 3) Dust Handling: Built-in collection. 4) Control Features: Adjustable feed, safety stops. 5) Support: Warranty, service, spare parts availability. 6) Price vs. Productivity: ROI, lifetime cost.

5. Maintenance Best Practices

Owning an industrial sanding machine is a long-term investment. Proper Maintenance keeps your sander running smoothly and your output top-notch. Follow these best practices:

-

Keep It Clean: After each shift, clear the machine of dust and debris. Use a vacuum or compressed air on rollers, belt paths, and motors. Excess dust can burn out motors and affect sanding quality.

-

Inspect and Replace Abrasives: Check sanding belts/discs frequently. A worn or clogged belt reduces efficiency and can overheat. Replace belts or papers as soon as material removal slows. Stock spare like belts and pads so you can swap them quickly and avoid downtime.

-

Check Belt Tension and Alignment: Proper tension keeps the belt tracking true. Consult the manual to adjust tension periodically. Misaligned belts can tear or cut into the machine. Correct any drift promptly.

-

Lubricate Moving Parts: Many machines have chains, bearings, or gears. Apply lubricants as recommended by the manufacturer. This prevents wear and keeps movements smooth.

-

Monitor Rollers and Motors: Listen for unusual noises or vibrations during operation. Regularly inspect sanding drums, contact drums, and feed rollers for wear or damage. Replace rollers if they show wear patterns. Keep motor shafts aligned and in good condition.

-

Calibrate and Test: Verify that sanding tables and heads are level and square. Use measuring blocks or gauges to check that thickness settings are accurate. Recalibrate as needed to maintain precision.

-

Follow a Maintenance Schedule: Adhere to the maintenance plan in your machine’s manual. This includes periodic deep checks (e.g., every 3–6 months) of electrical connections, belt paths, dust ports, and safety systems.

-

Professional Service: Arrange annual servicing by qualified technicians. They can perform deep cleaning, belt tracking alignments, and component checks that you might not catch.

By keeping up with maintenance, you ensure safety and longevity. Well-maintained industrial sanding machines work at peak efficiency, minimizing scraps and costly repairs. This protects your ROI and keeps production uninterrupted

6. FAQ About Industrial Sanding Machine

What is the best sanding machine for wood?

The “best” sanding machine depends on your project size, budget, and finish goals.

For large flat surfaces, a belt sander (e.g., a 3×18-inch or 4×24-inch model) removes stock quickly. For finer finishing, an orbital or random-orbit sander (5-inch or 6-inch pad) provides uniform swirl-free results. For edge work and corners, a detail (corner) sander or delta sander excels. Top brands include Festool, Makita, Bosch, and DeWalt:

-

Festool ETS 150/3 (5″ random-orbit): Ultra-low dust, variable speed, concert-quality finish.

-

Makita 9403 (1/3-sheet belt-type): Great balance of power and low vibration for big jobs.

-

Bosch GSS23-125 (3-inch random-orbit): Compact for corners, affordable.

Choose a sander type based on surface area, desired finish level, and ergonomics.

What is a big sanding machine called?

A large sanding machine used for aggressive stock removal on big panels is commonly called a belt sander (especially in woodworking shops). In industrial/commercial settings, the largest multi-head machines are called wide-belt sanders or panel sanders.

-

Belt Sander: Handheld (e.g., 3×21″, 4×24″) used for leveling boards, removing old finishes.

-

Wide-Belt Sander: Stationary machine with a conveyor table; belts range from 18″ to 54″ wide. Ideal for sanding large cabinet doors, plywood sheets, and tabletops.

-

Drum Sander: Another shop-machine name; uses a spinning drum wrapped with sandpaper to flatten planks, often 3 to 4 feet wide.

What are the 4 types of sanders you can use to sand wood?

Four common sander types for wood projects include:

-

Belt Sander:

-

Best for fast material removal on large boards.

-

Available in hand-held (e.g., Makita 9403) and floor-standing/drum (shop) versions.

-

-

Random-Orbit Sander (ROS):

-

A 5″ or 6″ round pad that both spins and orbits.

-

Produces swirl-free finishes, ideal for cabinetry, furniture tops, and plywood.

-

-

Finishing (Sheet) Sander:

-

Uses a 1/2-sheet or full-sheet rectangle pad.

-

Moves in a straight, orbital direction; good for final sanding before paint or stain.

-

-

Detail (Corner) Sander:

-

Small, triangular sanding pad.

-

Great for sanding inside corners, tight spaces, and small decorative pieces.

Each has its own grit ranges; select coarser grits (60–80) on belt sanders for stock removal, mid-range on ROS (100–120) for smoothing, and fine (180–220+) on finishing sanders.

-

What are the biggest sanding mistakes to avoid with a sanding machine?

Skipping Grit Progression: Starting at too fine or too coarse a grit. Jumping from 60 to 220 grit can leave visible scratches. Use a systematic path (e.g., 80 → 120 → 180 → 220).

-

Excessive Pressure: Pressing down on the sander will cause uneven cuts, “dishing,” or gouges. Let the weight of the machine do the work.

-

Incorrect Sandpaper Type: Using metal-bonded or masonry sandpaper on wood can clog or leave burns. Always use wood-grade abrasive.

-

Not Securing the Workpiece: Sanding a loose board can cause kickback, uneven sanding, or scratches. Clamp the piece firmly.

-

Over-Sanding Edges: Focusing too long on edges removes more material than intended, causing rounded corners instead of square edges.

-

Ignoring Dust Collection: Sanding without vacuum or dust bag leads to clogged grit, reduced efficiency, and health risks from fine dust.

-

Not Checking Pad Condition: Worn-out or torn backing pads cause tear-out or swirl marks. Replace pads when adhesive fails or foam compresses.

What is the difference between a grinder and a sanding machine?

Grinding Machine:

-

Uses abrasive wheels or discs to remove metal or very hard surfaces.

-

Higher RPMs and coarser grit, designed for metal, masonry, or heavy-duty material removal.

-

Generates significant heat; not ideal for wood as it can burn or chatter the surface.

-

-

Sanding Machine:

-

Uses sandpaper or sanding belts with grits designed for wood, composites, and softer materials.

-

Typically spins at lower RPMs (though still fast) but “orbits” (ROS) or uses fine-grain belts for smoother wood removal.

-

Designed to minimize heat, reduce tear-out, and maintain consistent surface finish on wood or painted surfaces.

In short, a grinder is for metal or masonry, whereas a wood sander is optimized for controlled, fine stock removal and smooth finishes on wood.

-

What grit is used for sanding wood?

Grit selection depends on task stage:

-

Initial Stock Removal (Rough): 36–60 grit (belt sander, coarse ROS).

-

Surface Smoothing (Intermediate): 80–120 grit (ROS or finishing sander).

-

Pre-Finish Sanding: 150–180 grit (finishing sander or ROS).

-

Between Finish Coats: 220–320 grit (finishing pad or hand-sand).

-

Ultra-Fine Polishing (Optional): 400–600 grit (fine finish, lacquer sanding).

Always follow a progressive grit sequence—skipping too many grit levels can leave deep scratches that show through finish.

7. To Sum Up

Embrace precision and productivity with the right Industrial Wood Sander.

By understanding your needs and choosing a powerful, well-supported machine, you unlock next-level results – faster throughput, higher-quality finishes, and real cost savings.

Contact Us. Start exploring sanding solutions today to see how an industrial sander can revolutionize your wood processing.