In modern furniture and cabinet manufacturing, the surface finish of a wooden door is as critical as its design and construction. High-quality finishes not only protect the door but also define its visual appeal and perceived value.

Spray Painting has become a cornerstone of the finishing process for wooden doors and cabinet components. It delivers a smooth, even coat of paint or lacquer across all surfaces and contours, far beyond what brushing or rolling can achieve.

This article examines why spray painting is so important in wooden door manufacturing and highlights its technical and practical benefits.

Featured Resource

Table of Contents

1. Why Spray Painting Is Essential in Wooden Door Manufacturing

Spray Painting is typically one of the final steps in the production of wooden doors, following surface preparation (sanding and priming) and before assembly or finishing touches.

Its primary role is to apply a uniform coating of paint, stain, or lacquer that adheres deeply into the wood grain and seals the surface. Unlike manual brushing or dipping, spray application can cover complex door profiles, raised panels, and recesses without leaving brush strokes or drips.

In practice, Spray Booths or Paint Rooms are set up in manufacturing plants to control the environment during this stage. Wood doors are typically hung or placed on carriers, and high-volume spray guns or robotic arms apply multiple thin coats quickly.

This automated approach produces consistent results and greatly reduces the variability inherent in hand-painting. The even layer of finish also improves the door’s adhesion and durability, effectively locking out moisture and contaminants.

Spray Painting transforms raw or primed wood panels into finished doors with a flawless surface, ready for installation in kitchens, cabinets, and furniture.

2. Advantages of Spray Paint Over Other Finishes

Spray can provides multiple advantages in wood door production efficiency and quality:

- Even Coverage, No Brush Marks: Spray systems atomize the finish into a fine mist that coats every visible surface uniformly. This eliminates brush strokes or roller marks.

- Faster Application and Drying: Industrial spray guns can apply a thin coat of paint much faster than manual methods.

- Complete Access to Complex Shapes: Cabinet and wardrobe doors often feature decorative moldings, raised panels, or grooves. Spraying penetrates these hard-to-reach areas uniformly. The fine spray mist flows into nooks and crannies, something a paintbrush might skip over or require careful detailing.

- Reduced Downtime for Color Changes: In a factory setting, spray lines can switch colors more efficiently. Using dedicated equipment (often with disposable cups or cleanable hoses), operators can flush and change paints quickly between jobs without the lengthy cleanup required for brushes. This agility reduces idle time when production must shift between different door colors or finishes.

Together, these advantages make spray finishing far more efficient than brushing or rolling, particularly for medium-to-large manufacturing runs.

3. Technical Benefits: Durability, Appearance, and Consistency

Beyond the obvious visual improvements, Spray Painting imparts technical advantages that enhance the durability and longevity of wood doors:

- Durable Protective Coating: Automated Spray Systems precisely control film thickness and layering, creating a robust barrier on the door’s surface. It can protective layer helps prevent the wood from swelling or warping due to humidity. Coatings also block out dirt and oils, making doors easier to clean and less likely to discolor over time (“Stain Resistance”)

- Flawless Appearance (Gloss and Texture Control): Spray equipment can accommodate a range of finishes, from ultra-matte to high-gloss.

- Uniform Thickness and Coverage: Automated Spray Machines can produce the same coating thickness on each panel, every time.

In sum, spraying improves both the look and function of wooden doors. It yields a premium, showroom-quality surface while imparting hard-wearing protection.

4. Common Materials and Paint Types for Wood Doors

Wooden doors and cabinet fronts can be finished with a variety of coating chemistries. The choice of paint depends on the desired appearance, durability, and environmental regulations. Common spray-applied coatings include:

-

Nitrocellulose Lacquers (1K): Traditionally used for fine furniture, nitrocellulose lacquers dry quickly to a high gloss. They are easy to spray but emit high levels of VOC. They are less common now due to environmental concerns.

-

Catalyzed (2K) Lacquers and Polyurethanes: These two-component finishes cure via a chemical catalyst, producing a very hard, durable surface. They are ideal for doors that require heavy scratch and chemical resistance (such as kitchen cabinets). Many 2K systems can be sprayed, but require careful handling (mixing with hardener) and longer cure times.

-

Water-Based Lacquers and Polyurethanes: These are newer formulations that use water as the primary solvent. They have much lower odor and VOC emissions while still providing good hardness and clarity. Many cabinet makers now prefer water-based topcoats to meet stricter air quality laws.

-

Stains and Primers: Before color or clear coats, doors are often treated with stains (to add color to the wood) and sealers or primers. These are usually solvent or water-based and sprayed as well.

-

UV-Curing Varnishes: In some high-end or ultra-fast lines, doors may be coated with a UV-curable finish. After spraying a thin coat, the panel passes under UV lamps that instantly cure the varnish. It can be done in seconds, eliminating most drying time. UV-curable coatings are often acrylate-based and form very durable films. This method requires specialized equipment (UV booths) but greatly increases line speed.

-

Specialty Coatings: Other options include acid-cure varnishes, polyester paints, or specialty textured finishes. Some manufacturers even use an “electrostatic” spray method, where charged paint particles are attracted to the grounded wood surface, improving transfer efficiency.

In short, the spray booth must be compatible with whatever chemistry is chosen. The actual materials used will be dictated by the customer’s durability requirements, budget, and local regulations.

5. Essential Equipment and Systems

Efficient Spray Painting of wooden doors depends not only on the paint itself but on the right machinery and accessories. Key pieces of equipment commonly used in a door manufacturing finish line include:

5.1. Wide Belt Sanding Machine

Before any paint goes on, door panels must be flat and smooth. Wide Belt Sanders are heavy-duty conveyors with abrasive belts that quickly level and finish panels. They are routinely used to sand rough material until the surface is flat and smooth for coating and yielding a flawless final appearance.

5.2. Paint Spray Room

Paint Spray Room is equipped with powerful exhaust fans and filters to capture airborne paint particles and solvents. The spray booth provides a safe, clean, and well-lit environment that is essential for consistent finishes. Many booths are classified (according to NFPA-33 codes, for example) to be explosion-proof and fire-safe when spraying flammable coatings.

5.3. Disposable Spray Gun Cups

Spray Guns typically feed paint from a cup attached to the gun body.

Traditional metal cups must be cleaned with solvents between color changes. Disposable spray gun cups (and their liners) eliminate this cleanup step.

They deliver paint directly to the gun without extra mixing containers, so every color change is fast and clean. Because each cup liner is used only once, there’s no risk of a stray drop of old paint spoiling the next batch.

5.4. Industrial Paint Drying Rack

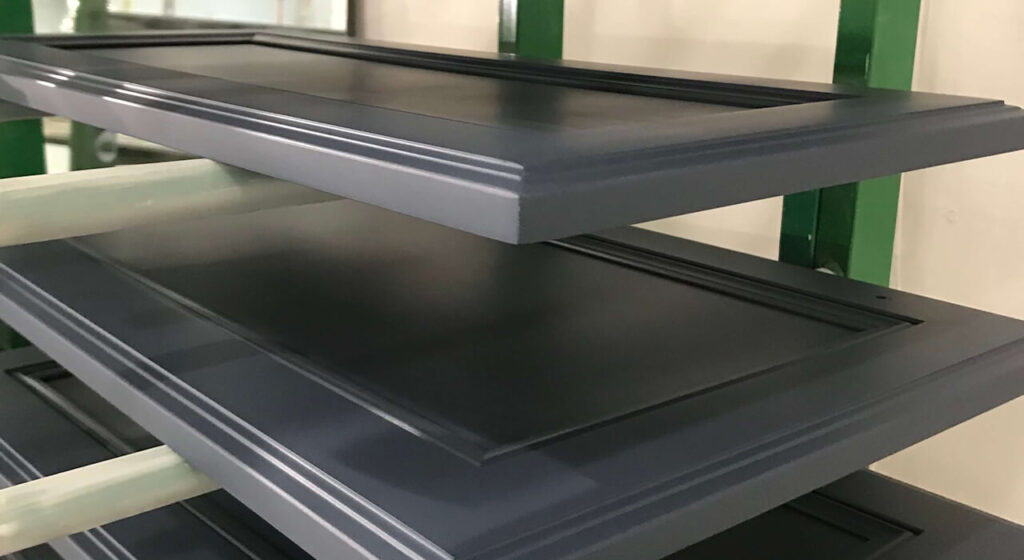

After painting, the doors must dry and cure without being disturbed. Here, an industrial drying rack or cart is indispensable. Our Industrial Paint Drying Racks are designed to help you dry multiple items like cabinets, doors, and trim with ease while saving valuable space in your workshop.

5.5. Automated Cabinet Door Painting Machine

Finally, for maximum efficiency, many modern cabinet makers use automated door painting machines. These are complete systems – often robotic – designed specifically for spraying cabinet fronts, drawer faces, and doors.

6. How Do You Paint Raw Wooden Doors

Painting raw (unfinished) wood doors requires several careful steps. Below is a detailed professional workflow – from prep to finish – tailored for spray application on door-sized panels.

-

Prepping the Door:

-

Sand Smoothly: Sand the door’s faces and edges to make the surface uniformly smooth. Start with medium-grit (e.g. 120-grit) to level rough spots, then finish with fine-grit (180–220) paper.

-

-

Priming the Door:

-

Choose Primer: Select a primer suitable for raw wood – typically an all-purpose wood primer (shellac or acrylic) is best. As noted above, use one coat on all sides of the door. This seals the wood and creates a good bond for paint.

-

Spraying Primer: Use a spray gun or can, holding about 10–12 inches from the surface and applying in steady, overlapping passes. If using a spray booth or room, vent the primer fumes safely.

-

Drying Time: Let primer dry completely (follow product instructions).

-

Light Sand After Primer: Once dry, lightly sand the primed surface with 220-grit. This knocks down any raised grain or dust nibs. Clean off the dust again.

-

-

Selecting and Mixing Paint:

-

Paint Type: Pick a high-quality paint formulated for wood. If using liquid paint, thin it slightly if recommended for your spray system (consult spray gun manual or paint maker).

-

Strain Paint: Pour paint through a filter or strainer into your spray cup or gun reservoir. This removes lumps that could clog the nozzle.

-

Use Disposable Cups: To save cleaning time, consider disposable spray gun cups. These are plastic liners for your cup that you throw away after use.

-

-

Setting Up the Spray Area:

-

Ventilation and Booth: Ideally, spray in a dedicated paint spray room or booth. A proper spray room has filtered airflow and ample lighting – both of which enhance finish quality.

-

Safety Gear: Wear a respirator rated for paints, safety glasses, and appropriate clothing. Have air filters or exhaust fans running.

-

-

Spraying the Door:

-

Technique: Hold the spray gun about 8–12 inches from the surface. Use smooth, even strokes parallel to the door, overlapping each pass by about 50%. Apply paint in multiple thin coats, not one heavy coat. Thin coats prevent runs and ensure even coverage.

-

Edges and Panels: Tip the door slightly or approach at an angle for edges and recessed panels to avoid pooling. One tip: spray towards the center of panels first, then edges – this “from the inside out” approach prevents drips on the face.

-

Manage Overspray: If you don’t have a booth, use cardboard shields or drop cloths. Always wipe up stray overspray immediately with a solvent cloth.

-

-

Drying and Curing:

-

Drying Racks: After spraying, immediately transfer the door to a Drying Rack.

-

Curing Time: Allow sufficient cure time before handling.

-

Light Sanding Between Coats: For the absolute best finish, a very light sanding (220–320 grit) between coats can remove any small imperfections. Always clean off dust before subsequent coats.

-

-

Finishing Touches:

-

Final Inspection: Check for missed spots or dust specs. If found, lightly sand and touch up as needed.

-

Topcoat (Optional): For extra durability or sheen, apply a clear polyurethane or varnish. Many cabinet shops add a water-based clear coat over the color. Spray polyurethane can add depth and resistance to wear and moisture.

-

7. FAQ

Can You Spray Paint Wooden Doors?

Yes – spraying is an excellent method to paint wood doors of all kinds. Modern spray-paint formulations (especially aerosol or HVLP spray paints) are specifically designed to adhere to wood and create a smooth, even film.

What Is the Best Paint for Wooden Doors?

Choosing the right paint is crucial. For wooden doors, the best paint often depends on the door’s location and usage:

-

Interior Doors (households, kitchens, closets): Many professionals use water-based acrylic latex or alkyd enamel paints.

-

Exterior Doors (front doors, weather-exposed): Use exterior-grade paints designed to withstand moisture and UV light.

-

Finishes and Sheens: Glossy or semi-gloss finishes are often chosen for front doors and kitchen cabinets for durability and ease of cleaning.

Is It Better to Spray Paint or Brush Paint Wood?

- Superior Finish Quality

- Speed and Coverage: Spray guns cover large areas rapidly.

- Consistency: Automated or skilled spray application delivers uniform film thickness.

Can I Paint a Wood Door Without Sanding?

Preparing the surface is critical for a durable finish. Sanding is normally recommended to smooth the wood, remove old finishes, and promote paint adhesion.

Will Spray Paint Make Wood Waterproof?

Spray paint can add a degree of water resistance, but it does not make wood fully waterproof on its own. A good quality exterior spray paint or enamel will seal the wood’s surface and repel light moisture.

Do I Need to Prime a Wood Door Before Painting?

Spray paint can add a degree of water resistance, but it does not make wood fully waterproof on its own. A good quality exterior spray paint or enamel will seal the wood’s surface and repel light moisture.

8. To Sum Up

Spray paint is not just a decorative finish—it is a core part of modern woodworking that improves the durability, beauty, and efficiency of wooden door production.

By integrating Bestin Woodworking Machines, manufacturers can achieve top-tier results with lower labor, better consistency, and faster throughput.