Furniture Machines are powerful machines that streamline and boost production in the woodworking and furniture industries.

Industrial furniture factories use advanced machines like CNC Routers, Lathes, and Automated Edge Banding Machine to mass-produce cabinets, chairs, doors, and more.

This guide introduces the most important furniture machine types, explains how to buy them. By understanding these machines, you’ll be well-equipped to improve productivity and quality in any furniture workshop.

Let’s Go !!!

Featured Resource

Table of Contents

1. Key Types of Furniture Machines

Modern furniture production relies on a variety of specialized woodworking machines, each designed for a specific task. Below are common furniture machine types used in factories and workshops:

1.1. Sliding Table Saw

Sliding Table Saw (also Panel Saw) combines a circular blade with a sliding worktable. It is designed to cut large panels and boards accurately.

In furniture shops, sliding saws are ideal panel cutting solutions for cutting sheet goods used in cabinets and millwork.

The sliding table supports and feeds big panels through the blade, allowing Precise Crosscuts and Pip Cuts on sheet stock with safety and high accuracy.

Industrial sliding table saws have robust construction (heavy cast-iron table and rollers) to ensure stability and repeatability. They are essential for sizing plywood, MDF, and other panels used in furniture frames and shelves.

1.2. Edge Banding Machine

Edge Banding Machines automatically apply and trim material (PVC, veneer, or wood tape) to cover the raw edges of panels.

Edge banders are automated woodworking machine that perform pre-milling, gluing, trimming, scraping, and polishing on panel edges.

In furniture production, edge banding gives panels (like cabinet sides or shelves) a clean, finished edge. Modern edge banders can complete all edge-milling and trimming steps in one continuous pass, greatly increasing speed and uniformity.

These machines are indispensable for adding durable decorative edges to melamine, MDF, or plywood furniture parts.

1.3. CNC Nesting Machine

CNC Nesting Machines are specialized routers or machining centers that cut many parts from large panels while minimizing waste.

In nested-based manufacturing, software arranges (“nests”) all furniture parts onto sheet stock to use material efficiently.

A CNC nesting machine cuts the parts directly from wood, MDF, or plywood panels. Nesting simplifies cutting parts to size, especially when there are many small parts with different shapes.

By maximizing material yield and minimizing offcuts, CNC nesting drastically reduces waste and material costs in furniture production. This technology boosts profitability by using every inch of panel material effectively.

1.4. Tenoning Machine

Tenoning Machine cuts rectangular tenons (protruding wood joints) onto workpieces.

Tenons fit into matching mortises to form strong joints in furniture frames. Modern tenoners cut tenons quickly with much greater accuracy than manual hand tools. CNC Tenoners use computer control to produce complex tenons with high precision.

1.5. Mortiser Machine

Mortiser (hollow-chisel mortiser) drills square or rectangular holes (mortises) into wood. These mortises pair with tenons to form the classic mortise-and-tenon joint.

Mortisers can cut mortises remarkably quickly and accurately using a square chisel and drill bit in tandem.

1.6. Drilling Machine

Drilling Machines (drill presses or multi-spindle boring machines) create precise cylindrical holes in wood. These holes are essential for screws, dowels, hardware (like hinges), and other fasteners in furniture assembly.

A woodworking drill press can drill holes for screws and bolts to tight tolerances, ensuring secure joints in cabinets, tables, and chairs. CNC Drilling Machines automate the process, producing dozens of holes at once with consistent accuracy.

1.7. Spindle Moulder (Shaper)

The Spindle Moulder (also called a Wood Shaper) uses a vertical, high-speed spinning cutter (or cutters) to profile and shape wood edges and moldings.

It can trim profiles, grooves, and decorative contours on panels and moldings. Spindle moulders are essential woodworking machines that produce precise, detailed and complex profiles on wood.

In a furniture factory they shape parts like door frames, trim edges, and machine grooves for joinery. Different cutters can be mounted to create almost any edge or profile, making the spindle moulder extremely versatile and precise in furniture manufacturing.

1.8. CNC Wood Lathe Machine

A CNC Wood Lathe automates the turning and carving of wood around an axis. It’s an advanced, computer-controlled lathe for producing symmetrical wooden parts (legs, spindles, bowls, etc.).

In furniture making, CNC Lathes can turn chair legs, table legs, staircase balusters, and even artistic woodware automatically. They replace much of the manual woodturning process, ensuring high consistency and freeing skilled turners to focus on design.

1.9. Pressing Machine

Press Machines apply uniform pressure (and sometimes heat) to wood panels and veneers during glue-up.

In furniture factories, panels are often made by laminating layers of wood or adhesives together, and press machines hold the board flat until the glue cures.

There are two main types: cold presses (often hydraulic) that exert steady pressure, and hot presses that also heat the panel to speed up adhesive curing.

Hydraulic cold presses are reliable and cost-effective, while hot presses accelerate production by heating the glue layer.

1.10. Wide Belt Sanding Machine

Wide-belt Sander Machine (also called wide belt sanders or large belt sanders) are used to smooth and finish large panels and flat surfaces.

These machines feed big wood sheets under a wide abrasive belt, leveling any irregularities and producing a uniform finish.

They are essential in furniture factories for sanding tabletops, cabinet doors, plywood sheets, and other large panels.

1.11. Dust Collector

Dust Collector Systems are critical safety machines in any furniture workshop. They capture sawdust, chips, and airborne particles from cutting, sanding, and routing.

A dust collector (with a series of filters and fans) pulls in the dust from multiple machines, keeping the air clean.

In addition to health, dust collectors prevent dust buildup which can pose fire or explosion risks. High-quality shops integrate dust collection with all major machines (saws, sanders, routers) to maintain a safe, clean environment.

2. How to Buy Furniture Machines

Choosing the right machines requires careful planning. Here are key steps for buyers

2.1. Define Your Needs

List the functions you require (joinery, panel cutting, finishing, etc.) and your production volume.

For example, a high-volume factory might prioritize automated CNC machines and multi-spindle routers, while a smaller shop might start with essential stand-alone tools. Consider the materials (hardwoods, plywood, plastics) and dimensions you will work with.

2.2. Compare Specifications

Get detailed specs (power requirements, cutting capacity, speed, accuracy) from manufacturers.

Ensure the machine can handle your largest workpiece and meets precision needs. Review brochures and user manuals to match features with your requirements.

2.3. Inspect Build Quality

Whenever possible, inspect the machine physically before buying.

Check the frame and castings for cracks or damage. Examine moving parts for wear and smoothness. As one expert advises, look for cracks in welded joints, and test spindles or shafts for any play.

If buying used equipment, be extra vigilant: smell the motor for burnt windings and try to turn shafts by hand to check bearings.

2.4. Test Operation

Run a test cut or operation if the vendor allows it. Watch for excessive vibration, noise, or heat. On an edge bander, test the glue adhesion; on a lathe, inspect finish quality.

A trusted guide recommends watching manufacturer demos and trying a live test run to ensure the machine runs smoothly and meets performance claims.

Check controls and electronics for user-friendliness.

2.5. Evaluate Total Cost

Machine price is just one factor. Consider installation, tooling (blades, cutters, etc.), training, maintenance, and energy use. Factor in delivery and setup costs.

Also assess after-sales support: good training, warranty, and readily available spare parts are crucial for minimizing downtime.

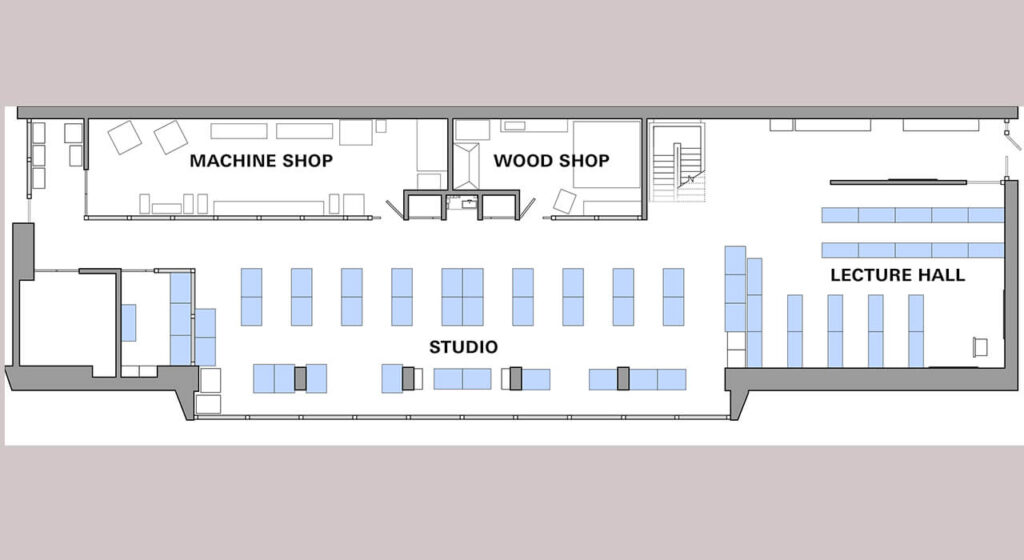

2.6. Plan the Layout and Safety

Ensure you have enough floor space and proper ventilation for dust collectors.

Verify electrical (3-phase vs single-phase) and air requirements. Make sure the equipment fits your shop layout and complies with safety standards (guards, emergency stops, CE marking, etc.).

3. Furniture Machine Prices

The price of furniture-making machinery varies widely by type and complexity. Here are typical price ranges for some common machines (USD):

| Machine Type | Typical Price Range (USD) | Remarks |

|---|

| Tenoning Machine | $4,000 – $20,000 | CNC tenoners are on the higher end; manual models are more affordable. |

| Mortiser Machine | $1,200 – $9,000 | Simple hollow chisel mortisers cost less; slot mortisers or CNC types cost more. |

| Drilling Machine | $1,000 – $15,000 | Multi-spindle and CNC boring machines cost more than manual drill presses. |

| Spindle Moulder | $3,500 – $18,000 | Depends on motor size, tilt function, and CNC control options. |

| CNC Wood Lathe Machine | $2,800 -$13,000 | Entry-level CNC lathes for turning wood spindles; dual-axis and tool-changing models are more expensive. |

| Pressing Machine | $5,000 – $30,000+ | Cold presses are cheaper; hot hydraulic presses with heating plates are more costly. |

| CNC Turning Machine | $6,000 – $25,000 | For precision turning of table legs, chair parts, balusters in bulk. |

| Edge Banding Machine | $600 – $32,800 | Manual edge banders start low; fully automatic with corner rounding are premium. |

| Wide Belt Sanding Machine | $5,000 – $40,000+ | Entry-level single-head; heavy-duty dual-head machines for production lines. |

| Dust Collector | $500 – $8,000 | Small bag units to industrial central systems; explosion-proof systems cost more. |

| CNC Nesting Machine | $15,000 – $65,000+ | Includes automatic tool changers, vacuum table, and nesting optimization software. |

| Sliding Table Saw | $6,500 – $26,500 | Depends on sliding table length, scoring unit, digital control, and power. |

4. General Maintenance Tips for Furniture Machines

- Daily Cleaning: Dust is your enemy—clean machines at the end of every shift.

- Lubrication Schedule: Grease bearings, gears, and rails weekly or as per manufacturer specs.

- Blade & Bit Checks: Dull tools damage both wood and machines—sharpen or replace as needed.

- Electrical Inspection: Monthly check of control panels, cables, and emergency stops.

- Calibration: CNC and precision machines should be calibrated quarterly for accuracy.

- Service Records: Keep a logbook for each machine (maintenance date, issues, replacements).

- Operator Training: Well-trained staff reduce wear and tear. Schedule refreshers annually.

5. To Sum Up

The world of furniture machines is vast, but understanding the core equipment — from edge banders and CNC routers to tenoners and wide belt sanders — is essential for any industrial furniture manufacturer looking to stay competitive.

These machines not only boost productivity and precision but also help factories produce higher-quality furniture faster and more efficiently.

At BESTIN, we help furniture factories of all sizes choose the right woodworking machines for their production goals.

Whether you need a high-speed edge banding machine, a precision CNC router, or a heavy-duty wide belt sander, we’ve got you covered with trusted machinery, expert support, and affordable pricing. Contact Us Now.