To choose a cabinet table saw, you need to match the machine to your workspace and woodworking projects. Pay attention to size, power, and safety. This article will guide you in finding a good cabinet table saw.

Let’s Go !!

Featured Resource

Table of Contents

1. What Is a Cabinet Table Saw?

Cabinet Table Saw are a strong woodworking machine. It is made to be very accurate and last a long time. Many professionals use this saw in their shops. It is different because it is heavy and has a solid base. The saw sits inside a sturdy cabinet.

This helps stop shaking and keeps the saw steady when you use it. The design lets you make very exact cuts each time.

Key Features

- The cabinet uses steel or cast iron. This gives the saw strength and keeps it steady.

- Motors are strong, from 3 to 5 horsepower. You can cut thick hardwoods and big sheets of wood.

- The table is large, usually between 24″x24″ and 30″x30″. This helps you work with big pieces of wood.

- You can move the miter and rip fences. This helps you cut straight and true.

- Safety parts include blade guards, riving knives, and sometimes auto-stop tech. These help keep your hands safe.

- Dust collection parts, like ports and shrouds, help keep your shop clean and safe.

- You can change the blade height and angle easily. This helps you make different kinds of cuts.

- The saw can cut wide boards, sometimes up to 52 inches.

Tip: A cabinet table saw is not just about being strong. Its design helps you stay safe and keep your shop tidy.

2. Cabinet vs. Other Saws

You might wonder how a cabinet table saw is different from contractor and hybrid saws. The main differences are in how strong, accurate, and powerful they are.

Here is a table to show you the differences:

|

Saw Type |

Durability & Build |

Precision & Performance |

Best For |

|

Cabinet Saws |

Heavy, closed cabinet, cast iron top |

Very exact, less shaking, easy to adjust |

Professional and tough jobs |

|

Contractor Saws |

Lighter, open base, not as strong |

More shaking, not as exact |

Beginners and small projects |

|

Hybrid Saws |

Medium weight, partly closed |

Good balance, less power than cabinet saws |

Home shops and hobby work |

Cabinet Saws are the heaviest and have the strongest motors. This means they shake less and cut more accurately. Contractor saws are lighter and not as steady. This can make your cuts less exact. Hybrid saws are in the middle. They have better dust control and are steadier than contractor saws, but not as strong as cabinet saws.

If you want a saw that will last a long time and give you great results, a cabinet table saw is the best pick. Many woodworkers choose this saw because it is strong, accurate, and safe.

3. Assess Your Needs

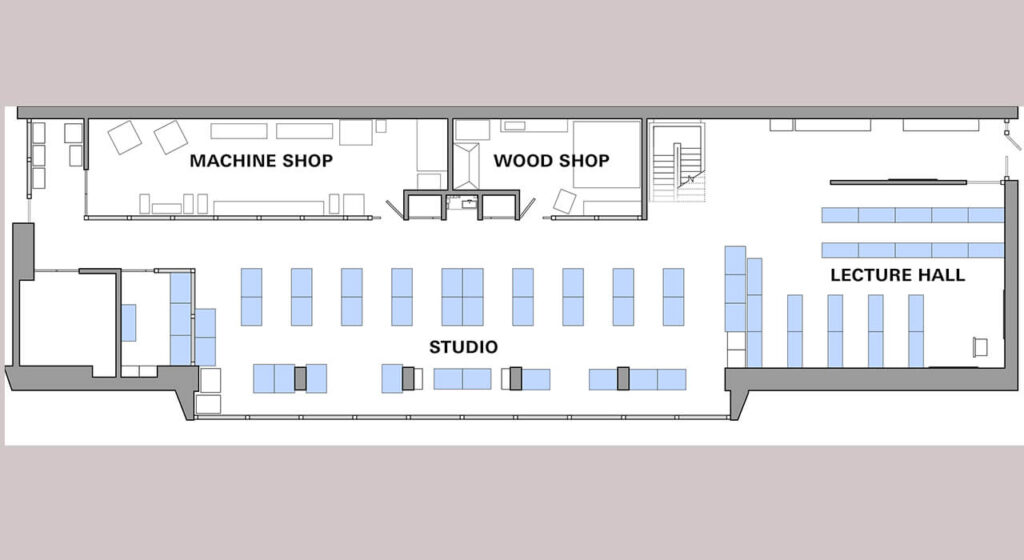

3.1. Shop Space

You need to plan your shop space before you bring in a cabinet table saw. These saws are large and heavy. They do not move easily. You must give them a permanent spot in your workshop.

Think about how you move wood through your shop. Place your saw so you have enough room for big boards on both sides.

- Let your available space guide your shop layout.

- Plan the path wood takes from the door to the finished project.

- Group machines you use together, like the jointer, planer, and table saw, close to each other.

- Store wood near the entrance. This makes it easier to bring in large sheets.

- Put the table saw at one end of the shop or in the center. Make sure you have clear space for infeed and outfeed.

- Keep a large open area in the middle of your shop. This helps you move around safely.

- Place your assembly table in the center. Keep clamps and hand tools nearby for easy access.

Tip: Always allow enough space around your cabinet table saw for safe and easy movement. This helps you work faster and keeps your shop safe.

You should also think about future changes. If you want to add more machines later, leave flexible paths and open areas. Overlapping infeed and outfeed spaces can help you fit more tools in your shop.

3.2. Power Requirements

A cabinet table saw needs a lot of power. Most models use motors between 3 and 5 horsepower. These motors often run on 230 volts and draw a lot of amps. You must check your shop’s electrical setup before you buy.

|

Motor Power |

Voltage |

Amperage |

Wiring |

|

|

8.85HP |

380 |

N/A |

3 Phase 380V |

|

|

SawStop Industrial Cabinet Saw |

5 HP |

230 |

19.7 |

Single-phase 230V |

|

Jet XACTA SAW |

3 HP |

230 |

14.5 |

Single-phase 230V |

|

DeWalt – DWE7491 |

N/A |

120 |

15 |

120V |

|

SawStop – CNS175 |

N/A |

120/220 |

14 |

120V / 220V |

|

Grizzly – G0771Z |

N/A |

120/240 |

20 |

120V / 240V |

You may need a dedicated circuit for your saw. Some models, like the SawStop Industrial Cabinet Saw, draw almost 20 amps. The Jet XACTA SAW uses 14.5 amps. These numbers show that a standard outlet will not work for most cabinet saws. You should ask an electrician to check your wiring before you install your saw.

Note: Always match your saw’s power needs to your shop’s wiring. This keeps your saw running well and helps prevent electrical problems.

3.3. Project Types

Think about the projects you want to build. Your work will help you decide what features you need in a cabinet table saw. If you cut large sheets of plywood or thick hardwoods, you need a strong motor and a big table. If you make small boxes or frames, you may not need as much power or space.

- Flatness of the table top is important for accurate cuts. Look for a saw with a table that is flat within 0.005 inches.

- A good rip fence helps you cut straight. Make sure it locks tight and stays parallel to the blade.

- If you cut angles, you need a miter gauge with stops at 45 and 90 degrees.

- Dust collection is important if you work indoors. A good dust port keeps your shop clean and safe.

- Choose a saw with enough power for your future projects. This helps you avoid upgrades later.

- Safety features like blade guards and riving knives protect your hands.

Tip: Match your saw’s features to your main projects. This helps you get the best results and makes your work easier.

If you plan to grow your skills or take on bigger jobs, choose a saw that can handle more than your current needs. This makes your investment last longer.

3.4. Usage Frequency

How often you plan to use your table saw matters a lot. If you work with wood every day, you need a machine that can

handle heavy use. Daily use puts stress on the motor, bearings, and table. You want a saw that stays accurate and safe after many hours of work.

If you use your saw only on weekends or for small projects, you may not need the most powerful model. Light use means less

wear and tear. You can focus on features like easy adjustments and safety.

Ask yourself these questions:

- Will you use the saw every day, every week, or just a few times a month?

- Do you plan to run the saw for long periods, or only for short cuts?

- Will you share the saw with others in a busy shop?

Tip: Write down how many hours you expect to use your saw each week. This helps you choose a model that matches your needs.

Here is a simple guide to help you decide:

|

Usage Level |

Description |

What to Look For |

|

Heavy (Pro) |

Daily, long hours, big projects |

Strong motor, solid build, top safety |

|

Medium (Hobby) |

Weekly, medium projects |

Good power, easy setup, safety |

|

Light (Occasional) |

Monthly, small jobs |

Basic features, simple controls |

If you plan to grow your skills or take on more work, choose a saw that can handle more use than you need right now. This

helps you avoid buying a new saw too soon.

Note: The more you use your saw, the more important it is to pick a model with strong parts and good support. A reliable saw saves you time and money in the long run.

4. Cabinet Table Saw Features

4.1. Motor Power

Motor power is one of the most important things to look at when you choose a cabinet table saw. The motor gives the saw its strength. You need enough power to cut thick wood and keep the blade spinning at the right speed.

Horsepower

Most cabinet table saws use motors with 3 horsepower (HP) or more. This is the standard for serious woodworking. A 3 HP motor can cut through thick hardwoods and full-size plywood sheets without slowing down. Some industrial models use 4 HP motors for even more power. If you pick a saw with less than 3 HP, you may find it struggles with tough jobs. Many users say that 3 HP is the best choice for long-term use.

Here is a table to help you see the differences:

|

Motor Power (HP) |

Typical Use / Benchmark |

Notes |

|

1.75 – 2 HP |

Light work, not true cabinet |

May overload on thick cuts, not for heavy use |

|

3 HP |

Standard for cabinet table saws |

Handles thick hardwoods, best |

|

4 HP |

Industrial-grade, heavy-duty work |

For demanding, high-volume shops |

Tip: Choose a cabinet table saw with at least a 3 HP motor if you want to cut thick wood or work for long hours.

Voltage

Note: Always check your shop’s wiring before you buy a cabinet table saw. The right voltage keeps your saw safe and powerful.

4.2. Table Flatness

A flat table is key for making straight, accurate cuts. The table on a cabinet table saw is usually made from cast iron or steel. This makes it heavy and stable. A flat table keeps your wood from rocking or tipping as you push it through the blade.

Manufacturers test table flatness using special tools. Many aim for a flatness within 0.005 inches. Some tables use nickel plating to make the surface harder and more resistant to wear. This helps the table stay flat for many years, even in humid shops. Nickel plating also protects against rust.

|

Aspect |

Measurement / Test Result |

Description / Impact |

|

Table flatness |

Within 0.005 inches |

Ensures straight, accurate cuts |

|

Nickel plating hardness |

Keeps table surface strong and

flat over time |

|

|

Corrosion resistance |

Passes high-temp, acid tests |

Prevents rust, keeps table

smooth in any environment |

Tip: Run your hand over the table before you buy. A smooth, flat surface means better cuts and safer work.

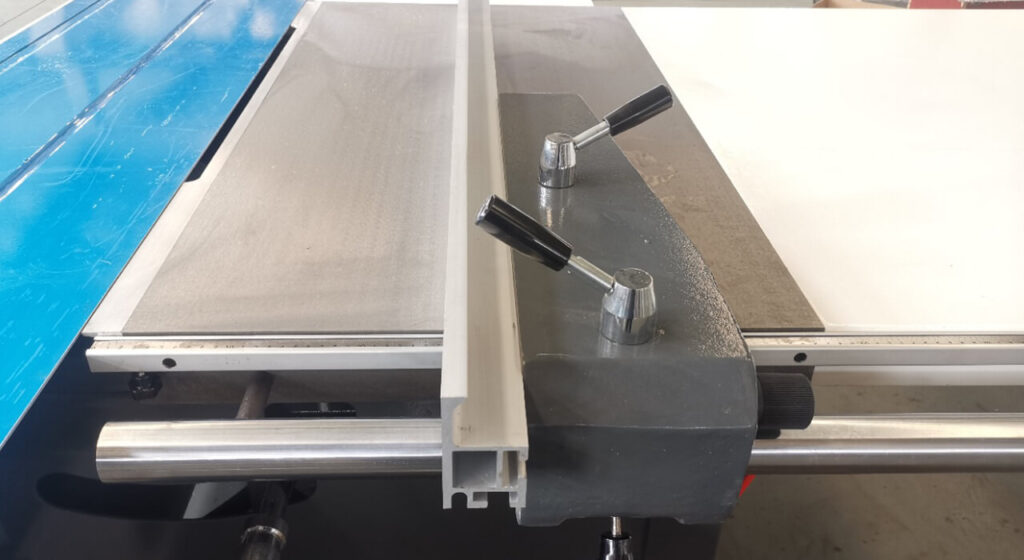

4.3. Fence System

The fence system helps you make straight cuts every time. A good fence locks in place and stays parallel to the blade. This keeps your wood from drifting as you cut. Most cabinet table saws use a heavy-duty fence with a smooth sliding action.

Some fences use a dual-axis guide rail system. This lets the fence move smoothly and lock down tight. The best fences stay flat across their whole width. Some users notice a small bow in the fence, but this is usually less than 0.004 inches. You can fix this by adding a flat piece of MDF to the fence.

Here are some features to look for in a fence system:

- Micro-adjustment knob for fine tuning

- Clear scale viewer to read measurements easily

- Dual-end locking to prevent fence movement during cuts

- Smooth sliding rails for easy adjustment

|

Fence Feature |

Measurement / Test Result |

Description / Impact |

|

Fence movement accuracy |

0.15 mm over full length |

Smooth, precise movement for |

|

Fence position accuracy |

Within 0.02 mm (0.0008″) |

Keeps fence parallel to blade, prevents deflection |

|

Scale viewer |

K9 Crystal Glass, 92% light pass |

Easy to read, reduces measurement errors |

Note: A precise fence system helps you cut safely and get the same results every time. Look for easy adjustments and a strong lock.

4.4. Safety

When you use a cabinet table saw, safety should always come first. Table saws can cause serious injuries if you do not use the right safety features. Many accidents happen even to experienced woodworkers. You need to know how each safety part works and why it matters.

Riving Knife

A riving knife sits behind the blade. It moves up and down with the blade. This tool keeps the wood from pinching the blade and kicking back toward you. Kickback is one of the most dangerous risks when using a table saw. The riving knife helps stop the wood from binding and flying back.

- The riving knife stays close to the blade at all times.

- It works for both straight and angled cuts.

- You do not need to remove it for most cuts, so you stay safer.

Blade Guard

The blade guard covers the spinning blade. It keeps your hands away from the sharp teeth. A clear guard lets you see your work while staying safe. Some guards also connect to a dust hose to help keep the air clean.

- The guard moves up as you push wood through the blade.

- It drops back down when you finish the cut.

- Some guards have anti-kickback pawls for extra safety.

Tip: Never skip safety steps. Even a quick job can lead to injury if you do not use the riving knife and blade guard.

4.5. Dust Collection

Dust Collection is important for both safety and cleanliness. When you cut wood, fine dust fills the air and lands on every surface. Breathing in this dust can harm your lungs. A good cabinet table saw has a built-in dust port. This port connects to a shop vacuum or dust collector.

- Most saws use a 4-inch dust port under the blade.

- Some models add a shroud around the blade for better dust capture.

- Blade guards with dust ports help catch dust above the table.

A strong dust collection system keeps your shop cleaner. It also helps you see your cut line better. Less dust means fewer slips and less time spent cleaning up. Always connect your saw to a dust collector before you start cutting.

Note: Clean air keeps you healthy. Good dust collection also helps your saw last longer by keeping dust out of moving parts.

4.6. Build Quality

Build quality affects how well your cabinet table saw works and how long it lasts. You want a saw that feels solid and does not shake when you cut. Look for a table made from precision-ground cast iron. This heavy material keeps the saw steady and helps you make accurate cuts.

- Welded steel frames and crisscross webbing stop the saw from warping or shrinking.

- The trunnion, which holds the blade, should attach to the base. This setup reduces wobble and noise.

- A strong rip fence made from hardened plastic or metal lets wood slide smoothly and locks in place.

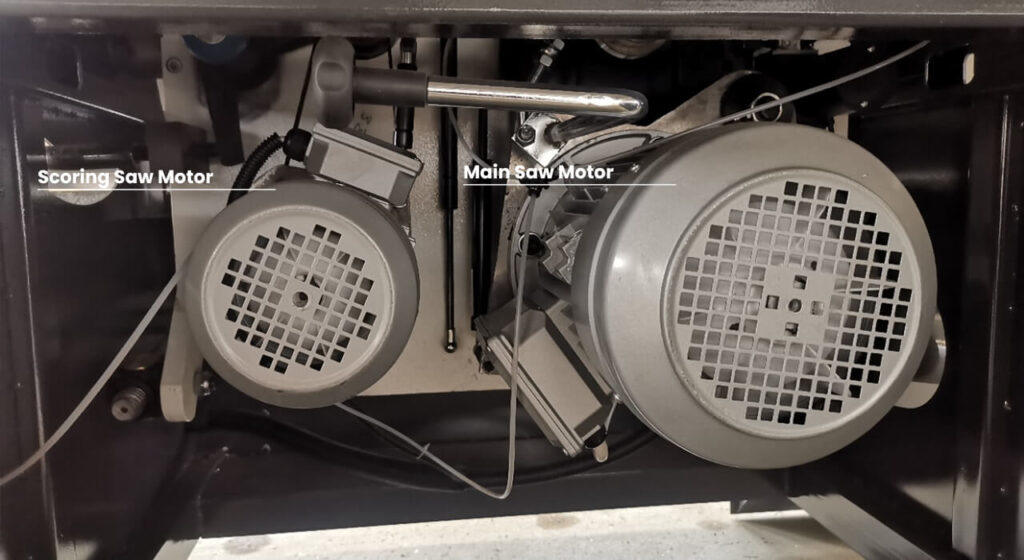

Some saws, like the Bestin Panel Saw, use these features to give you stable, accurate cuts every time. A good build means less vibration, less noise, and more control. Some models, like the SawStop Jobsite Table Saw JSS, have great safety features but may have fences that flex. This can make it harder to get perfect cuts. Always check the fence and table for strength and flatness before you buy.

Tip: A well-built cabinet table saw will serve you for many years. It will help you work faster and safer.

4.7. Blade Compatibility

Blade compatibility tells you what types of blades you can use with your saw. This feature affects the kinds of cuts you can make and the materials you can work with. If you pick the right blade, you get smoother cuts and safer results.

Most cabinet saws use a 10-inch blade. This size works for many woodworking projects. You can find blades for ripping, crosscutting, or cutting plywood. Some saws also accept 12-inch blades, but these are less common in home shops.

What to Check for Blade Compatibility

- Arbor Size: Most saws use a 5/8-inch arbor. Always check the arbor size before you buy new blades.

- Blade Diameter: The standard is 10 inches. Using a different size can cause problems or even damage your saw.

- Blade Thickness (Kerf): Thin-kerf blades remove less wood. They work well with less powerful motors. Full-kerf blades are thicker and need more power.

- Maximum Blade Height: This tells you how thick a board you can cut in one pass. Most 10-inch saws cut up to 3 inches deep.

- Dado Blade Support: Some projects need dado cuts. Check if your saw can use dado blade sets. Not all models support wide dado blades.

|

Feature |

Typical Value |

Why It Matters |

|

Blade Diameter |

10 inches |

Fits most woodworking blades |

|

Arbor Size |

5/8 inch |

Standard for most blades |

|

Max Blade Thickness |

1/8 inch (full) |

Affects cut width and motor load |

|

Dado Blade Width |

Up to 13/16 inch |

Needed for joinery and grooves |

Tip: Always use blades that match your saw’s specs. Using the wrong blade can cause

vibration, poor cuts, or even accidents.

Types of Blades You Can Use

You can choose from many blade types. Each blade works best for a certain job.

- Rip Blades: Cut along the grain. They have fewer teeth and remove wood fast.

- Crosscut Blades: Cut across the grain. They have more teeth for smooth cuts.

- Combination Blades: Handle both ripping and crosscutting. Good for general use.

- Plywood Blades: Have many fine teeth. They give clean cuts in sheet goods.

- Dado Sets: Make wide grooves. Check your saw’s manual before using them.

If you want to cut special materials like plastic or metal, you need special blades. Always read the blade label and your saw’s manual.

Why Blade Compatibility Matters

Choosing the right blade keeps your saw running well. It also keeps you safe. If you use a blade that does not fit, you risk damage or injury. The right blade also gives you cleaner cuts and less waste.

Note: Check your saw’s manual before buying new blades. This helps you avoid costly mistakes.

5. Compare and Choose

When you shop for a cabinet table saw, you will see many choices. Some brands are well-known because people trust them. Bestin has made strong and reliable saws for many years.

MJ6132TAZ

Feature

- Linear guide rail internal structure for more precise cutting.

- Electrical lifting for main saw blade ( electrical tilting optional).

- Cast iron table disassemble, easy for maintaince.

- ” Optional high precision crosscut dimension reader.

Model( Electric Up And Down Of Main Saw Blade ) | MJ6132TAZ | | Main Motor Power | 5.5kw | ||

Sliding Table Size | 3200*410mm | Scoring Motor Power | 1.1kw |

| ||

Gross Cut Capacity | 3200mm | Scoring Saw Blade Diameter | 120mm |

| ||

Width Between Saw Blade&Rip Fence | 1250mm | Scoring Saw Blade Speed | 8000rpm |

| ||

Saw Blade Diameter | 300(250-350)mm | Scoring Saw Diameter | 20mm |

| ||

Height Of Cut (300mm) | 70-80mm | Weight | 900kgs |

| ||

Main Saw Spindle Speed | 4500/6000rpm | Machine Body Package Size | 2200*1150*1100mm |

| ||

Main Spindle Diameter | 30mm | Sliding Table Pack Size | 3350*480*320mm |

| ||

Tilting Saw Blade | 0-45-90° | | |

| ||

6. Setup and Space

6.1. Footprint

A cabinet table saw takes up a lot of space in your workshop. You cannot move it easily once you set it up. Most models need a permanent spot because of their size and weight. The main body of a cabinet saw often measures about 19 inches by 19 inches. When you add the cast iron table and extension wings, the total width can reach over 44 inches and the depth about 27 inches. Some saws with larger extension tables or sliding features may need even more room.

You should plan for clear space around the saw. Experts recommend at least 16 feet in front and behind the blade and 5 feet on each side. This gives you enough room to handle big boards and move safely. For many woodworkers, this means setting aside about 320 square feet just for the saw and its work area. If you work with full sheets of plywood or use a slider saw, you may need up to 25 feet front to back and 14 to 16 feet side to side.

Tip: Use shop layout software like SketchUp or Inkscape to plan your space before you buy a saw. This helps you see how everything will fit.

|

Feature |

Dimension

(inches) |

|

19

3/8 W x 19 3/8 D |

|

|

Cast

Iron Table |

20

W x 27 D |

|

Cast

Iron Table w/ Extensions |

44

W x 27 D |

|

Extension

Table (36 inch) |

23

3/4 W x 27 D |

|

Overall

Saw Dimensions |

69

1/8 W x 33 D x 34 H |

6.2. Installation

Installing a cabinet table saw takes planning and effort. These saws are heavy, often weighing over 400 pounds. You may need help to move the saw into place. Make sure your floor can support the weight. Place the saw where you have enough room for infeed and outfeed. Leave at least 3 feet of walk-around clearance for safety and comfort.

You should check your shop’s electrical setup before installation. Most cabinet saws need a 220-volt outlet and a dedicated circuit. If you do not have this, call an electrician. Once you have the saw in place, check that it sits level. A level saw gives you better accuracy and safety.

Many woodworkers build a custom cabinet or base for their saw. This can raise the working height to about 38 inches, which feels comfortable for most people. A custom base also gives you extra storage and better dust collection.

Note: Always follow the manufacturer’s instructions for assembly and wiring. This keeps you safe and protects your investment.

6.3. Mobility Options

Cabinet table saws are not designed to move around your shop. Their weight and size make them stationary tools. You should plan for a permanent location. If you must move the saw, use a heavy-duty mobile base. Some brands offer special bases with locking wheels. These let you shift the saw a short distance if needed, but you should avoid moving it often.

Most woodworkers find that once the saw is set up, it stays in place for years. If you have a small shop, think about how you will bring in large boards and move around the saw. Good planning now saves you trouble later.

Tip: Focus on a layout that lets you work safely and efficiently. A fixed spot for your cabinet table saw helps you get the best results every time.

7. Where to Buy And To Sum Up

You can buy a cabinet table saw in many places. Or Contact Our Expert, we will recommend a right cabinet table saw to you.

Choosing the right cabinet table saw starts with knowing your shop space, power needs, and project plans. Check motor power for your wood types—3 HP works best for most users.

Compare saw types and focus on safety features like a locking rip fence and riving knife. Research brands, read reviews, and balance cost with long-term value.

Take your time and match the saw’s features to your woodworking goals. You will make a smart investment for years of safe, accurate work.

8. FAQ

What size blade does a cabinet table saw use?

Most cabinet table saws use a 10-inch blade. This size works for many woodworking projects. Always check your saw’s manual before buying new blades.

Do I need a special power outlet for a cabinet table saw?

Yes, you usually need a 220-volt outlet. Cabinet saws have strong motors that require more power than a standard 110-volt outlet provides. Ask an electrician to check your shop’s wiring before you install your saw.

How do I keep my cabinet table saw table flat?

Keep your shop dry and clean. Wipe the table after each use. Use a rust-preventive spray. If you see warping, contact the manufacturer for help.

Can I move a cabinet table saw by myself?

No, you should not move it alone. Cabinet table saws are very heavy. Always ask for help or use a heavy-duty mobile base with locking wheels.

What safety features should I look for?

Look for a riving knife, blade guard, and emergency stop switch. Some saws, like SawStop, have a safety system that stops the blade if it touches your skin.

How often should I clean the dust collection system?

Check and empty the dust collection bag or bin after every project. Clean the dust port and hoses once a month to keep airflow strong and your shop safe.

Can I use dado blades with my cabinet table saw?

Many cabinet table saws support dado blades. Check your saw’s manual for the maximum dado width and proper installation steps. Always use the correct throat plate for safety.