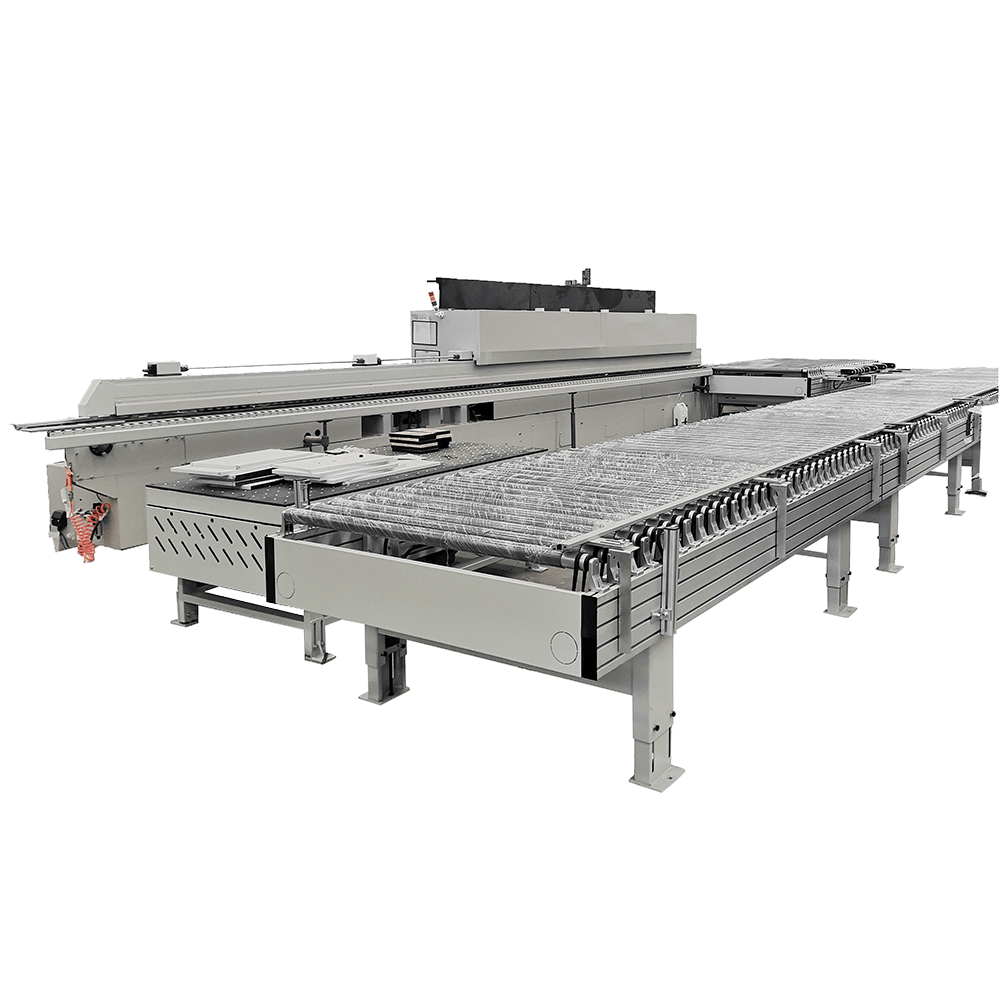

Automatic Edge Banding Return Conveyor

Automatic Edge Banding Return Conveyor

Automatic Edge Banding Return Conveyor UX-22

Unlock the full potential of your woodworking production with our roller-type returning conveyor line for edgebanding machines, the ultimate complement to your single-side edge banding machines. It is mainly used in the full-automatic edge banding assembly line for producing furniture board, cabinet board, and big-size and heavy-weight woodwork pieces. It can reduce costs and enhance efficiency.

Benefits

- Fast ROI: Payback In Serial Days a Month

Experience a rapid return on investment, with the Roller-type Returning Conveyor Line paying for itself in as little asserial days of month operation.

- Effortless Setup: Get Started Quickly

No extensive training is needed. Assembling and connecting this conveyor line is a breeze, ensuring you can start boosting your productivity right away.

- Flexible Operator Organization

Optimize your workforce with an economic one-man operation. This conveyor line adapts to your workflow, allowing you to do more with less.

- Ergonomic Operation

Prioritize the well-being of your operators. With this system, heavy physical work becomes a thing of the past.

- Enhanced Quality Control

Maintain superior quality standards and respond swiftly to material adjustments, ensuring precision in every workpiece.

Picture

Features

- Seamless Integration with BestIn Edge Banding Machines

The Roller-type Returning Conveyor Line perfectly aligns in terms of size, capacity, and speed with BestIn Group’s single-side edge banding machines. Achieve seamless synergy in your production.

- Optional Sensor-Controlled Turning Bolt

Effortlessly handle short and narrow parts, such as drawer fronts, with the optional sensor-controlled turning bolt. Precision meets efficiency with every use.

- Optional Small Roller Gib

The optional small roller gib provides essential support when working with wide workpieces, ensuring flawless results for every piece.

- Transform Your Edge Banding Process

Take your furniture and cabinet board production to new heights with the Roller-type Returning Conveyor Line. Automate, streamline and enhance your edge banding process for unparalleled efficiency and precision.

Technical Data

| Model | UX22 |

| Workpiece Range | 300*300-1200*2400mm |

| Workpiece Thickness | 10~60mm |

| Maximum Loading Weight | 100kg |

| Working Speed | 12~28M/min |

| Total Power Supply | 7.5KW |

- Part One: Machine Head-1

| External Dimension | L3500*W2330mm(1815)*H900±50mm |

| Roller Length | 1700mm and 1400mm |

| Main Beam | 240*50 Aluminum profile |

| Roller Dia | 56mm with rubber covered |

| Rubber Thickness | 3mm |

| Distance Between Rollers | 120mm |

- Part Two: Machine Head-2

| External Dimension | L3000*W2660mm (1615)*H900±50mm |

| Roller Length | 1500mm |

| Main Beam | 240*50 Aluminum profile |

| Roller Dia | 56mm with rubber covered |

| Rubber Thickness | 3mm |

| Distance Between Rollers | 120mm |

| Add With Bakelite Plate To Hold The Panel | |

- Part Three: Powered Roller Conveyor

| External Dimension | L6900*W1415mm*H900±50mm |

| Main Beam | 240*50 Aluminum profile |

| Roller Dia | 56mm with rubber covered |

| Roller Length | 1300mm |

| Rubber Thickness | 3mm |

| Distance Between Rollers | 120mm |

- Part Four: Pneumatic Ball-Floating Table

| Total Dimension | L2500*W1200*H800~900mm |

| Material Of The Table-Board | 8#U-steel with Bakelite plate |

| Main Frame | 60*40*3mm rectangular tube |

| Power Supply | 1.5 KW |

| With Lifting Function, Lifting Range Is Around 100mm | |

- Part Five: Pneumatic Ball-Floating Table

| Total Dimension | L1800*W600*H900±50mm |

| Material Of The Table-Board | 8#U-steel with Bakelite plate |

| Air Blower | 1.5 KW, brand |

| Leg | 60*40*3mm rectangular tube |

| Main Frame | 40*60 steel |

Video&Brochures

We Are Here For You!

- +86 166 7861 1290

- Info@bestingroup.com

- www.bestingroup.com