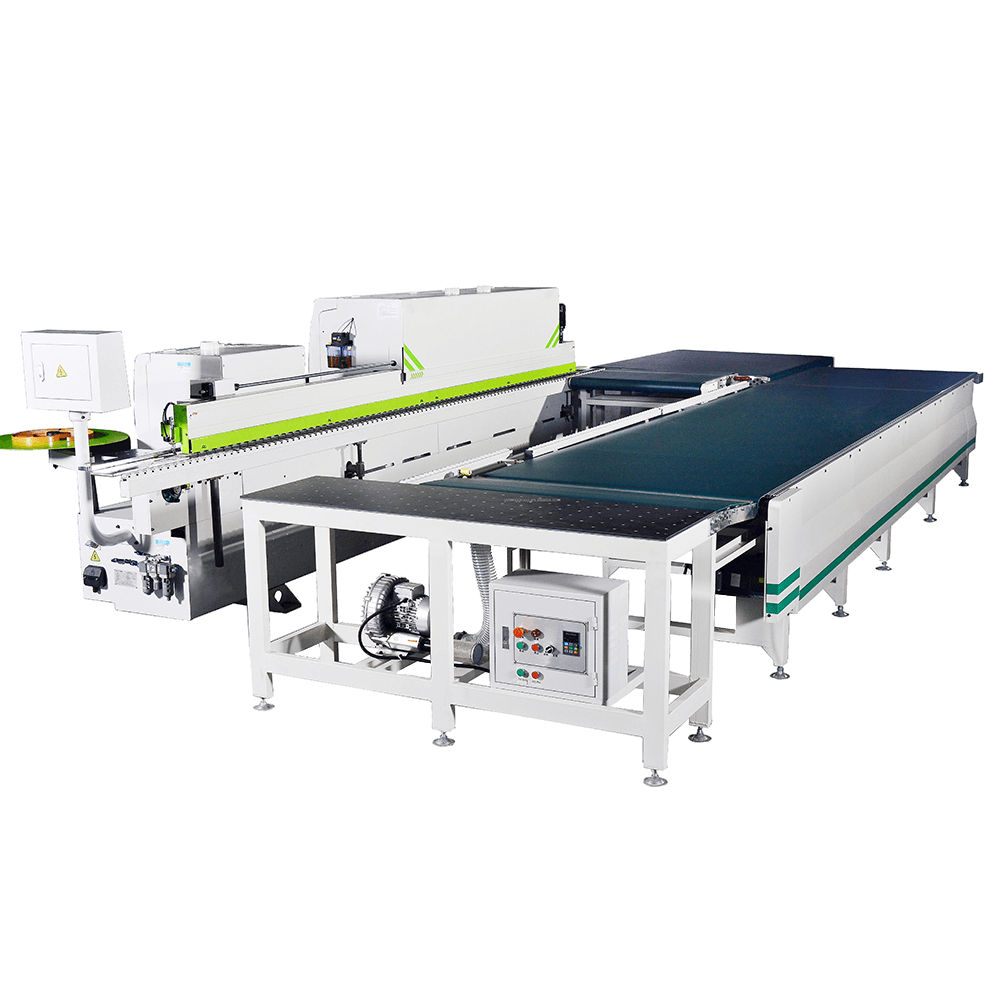

Nova Edge Bander Return Conveyor System

Nova Edge Bander Return Conveyor System

- Machine-Mate Transfer Roller Section

- Customizable Dimensions

- Polymer-Coated Rollers

- Fabricated Steel Frame

- Fully Synchronized Operation

- Independent Control Panel

Nova Edge Bander Return Conveyor System

The BESTIN Nova Series Edge Bander Return Conveyor streamlines panel handling by automating part return from the edgebander to the operator, reducing labor requirements and increasing throughput.

Its modular design offers seamless machine interfacing, customizable lengths and widths, and robust construction with non-marking, polymer-coated rollers.

Fully synchronized with your edge bander, the Nova system supports panels from 250 mm to 2,800 mm long, 8 mm to 60 mm thick, and up to 50 kg, all while ensuring stable, damage-free transport.

Benefits

- Lean Workflow & Labor Savings

Automating material flow with a return conveyor allows a single operator to manage both feeding and unloading—eliminating the need for a second operator at the edgebander outfeed and cutting labor costs significantly.

- Faster Throughput & ROI

Shops that pair their edgebanders with a return conveyor often see return-on-investment in under a year thanks to reduced manpower and fewer stoppages for part handling.

- Consistent, Damage-Free Handling

Polymer-coated steel rollers and gentle cross-transfer belts protect delicate panel surfaces—ideal for high-gloss laminates and sensitive finishes.

Picture

Features

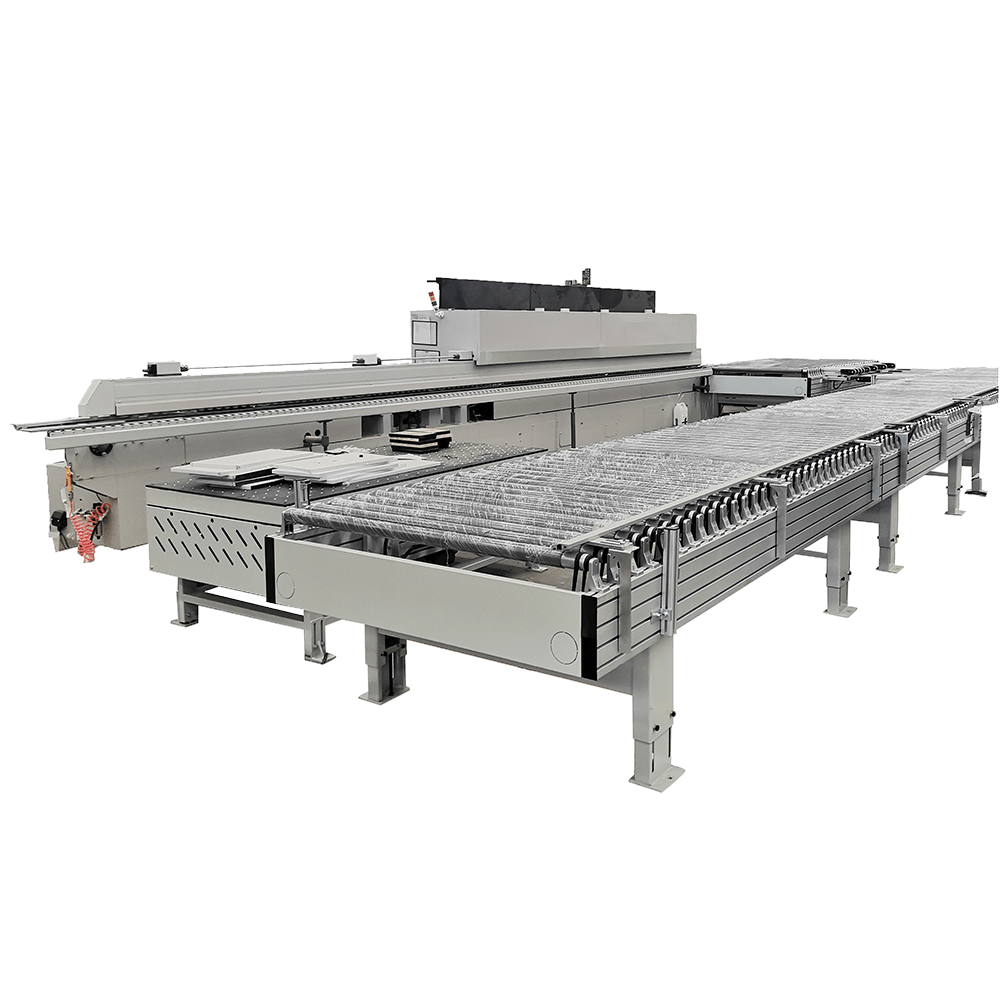

- Machine-Mate Transfer Roller Section

A dedicated transfer roller interface aligns precisely with any edgebander outfeed, ensuring panels flow smoothly onto the return conveyor without manual intervention.

- Customizable Dimensions

- Lengths & Widths: Tailored to your edgebander’s size, with return conveyors matching edgebander lengths for optimal layout.

- Panel Size Range: Handles workpieces from 200 mm (120 mm with optional Panel Deviator) up to 2,800 mm in length, 40 mm to 1,220 mm in width, and 8 mm–60 mm thick.

- Robust Construction

- Polymer-Coated Rollers: Provide strength and stability while maintaining a non-marking surface to prevent scratches and dents.

- Fabricated Steel Frame: Bolt-down feet and adjustable legs ensure rock-solid leveling, even under loads up to 80 kg per panel.

- Automation & Control

- Fully Synchronized Operation: Variable-speed control allows the return conveyor (30 m/min feed) to match the edgebander’s cycle—eliminating jams and optimizing part flow.

- Independent Control Panel: Dual-station control with an electrical cabinet panel and separate operator box offers safe, intuitive start/stop and speed adjustments.

- Optional Enhancements

- Inclined Buffer Roller Conveyor: A non-motorized, angled roller section at the outfeed provides extra staging capacity for stacked panels.

- Panel Deviator: Reduces the minimum return length from 200 mm to 120 mm for small parts handling.

Technical Data

|

Workpiece Length |

250-2800mm |

|

Workpiece Width |

40-1220mm |

|

4-Sided Processing* Min. Workpiece Length |

40*250mm |

|

4-Sided Processing* Max. Workpiece Length |

1220*2800mm |

|

Workpiece Thickness |

8-60mm |

|

Mass Per Unit Area |

25 Kg/M² |

|

Working Height |

835 – 950 Mm |

|

Feed Speed |

8 – 35 M/Min |

|

Workpiece Weight |

Max: 30kg (Workpiece Length≤700mm) |

|

Max: 50kg (Workpiece Length>700mm) |

Video&Brochures

We Are Here For You!

- +86 166 7861 1290

- Info@bestingroup.com

- www.bestingroup.com