PUR Edge Banding – the use of Polyurethane Reactive adhesives for panel edging – has revolutionized modern woodworking.

This guide dives deep into PUR edge banding, aimed at professionals seeking a complete, practical understanding.

Whether you’re upgrading your shop or improving product durability, the insights below will equip you to choose and apply PUR edge banding with confidence.

Featured Resource

Table of Contents

1. What Is PUR Edge Banding?

PUR Edge Banding is the process of using moisture-reactive polyurethane hot-melt glue to join edge tapes to panels, It yields a higher-performance edge compared to traditional hot melts.

In practice, a PUR Edgebanding process works like this: The machine’s PUR gluing unit heats the adhesive to about 120–150 °C, applies a thin bead or layer to the panel edge, and presses the pre-glued tape against it.

As the PUR cools, the bond forms; then over the next hours (and up to 48 hours full cure) the moisture reaction solidifies the joint. The result is an exceptionally strong, durable bond that is resistant to solvents, steam, and temperature swings.

PUR adhesives are formulated as 100% solids (no solvents) and are available in various forms (blocks, granules, or cartridges). They must be kept dry until used, and during application the machine must maintain the right temperature.

Because PUR cures slowly after application, it has a longer “open time” than EVA. It allows slight repositioning of tape if needed.

Its curing chemistry is irreversible – once bonded, the adhesive will not soften with reheating. As Neoflex explains, PUR hot-melts “react with the moisture… giving the product high resistance to temperature and extreme environmental conditions”.

In summary, PUR Edge Banding offers a chemically bonded, waterproof edge seam. It is widely used in cabinetry, furniture, and other panel processing where edge quality and durability are paramount.

2. Why Choose PUR Adhesive?

PUR adhesives bring dramatic performance improvements that often justify their cost. Woodworking professionals choose PUR edge banding for several powerful advantages:

2.1. Unmatched Bond Strength

PUR forms a true chemical bond with both the substrate and the edge tape. During curing, the adhesive crosslinks to form a robust matrix. The result is a bond far stronger than EVA hot-melts.

In practical terms, PUR-banded edges rarely delaminate or peel, even on bent or flexible components. This unmatched adhesion gives manufacturers confidence in product longevity and customer.

2.2. Superior Moisture and Heat Resistance

PUR bonds are highly water-resistant. Once cured, the adhesive repels moisture and withstands heat spikes. PUR creates a watertight and heat-resistant seal on the edge banding.

This makes PUR ideal for humid or wet environments (kitchens, bathrooms) and for cabinetry near ovens or heating elements.

Furniture and Cabinets finished with PUR edges stay intact under steam cleaning or tropical humidity, whereas EVA bonds can soften or weaken.

2.3. Thin, Invisible Glue Lines

PUR’s high adhesion allows you to use much less glue per joint. The glue line is extremely thin – often imperceptible. For visible-edge products (like glossy cabinets or light laminates), this minimal seam is a major aesthetic plus.

In comparison, EVA glue lines tend to be thicker and more opaque. Casa Custom notes that with PUR “the amount of glue used will be about 1 times less, and the glue line is less obvious”.

In other words, PUR allows virtually zero-line finishing, enhancing the appearance of high-end cabinetry.

2.4. Flexibility with Materials

A single PUR formula will adhere to PVC, ABS, wood, veneer, melamine and more.

This eliminates the need to switch adhesives when changing panel types. Even specialty tapes like textured woodgrain laminates or thick solid-wood edges can be glued with PUR if the machine supports it.

In practice, manufacturers appreciate that a PUR-capable edgebander handles all their common edge materials without recipe changes.

2.5. Clean, Environmentally Friendly Operation

Modern PUR adhesive systems have low VOCs (volatile organic compounds). It means workers breathe far fewer fumes compared to solvent-based glues. PUR’s “low VOC content” promotes a cleaner, healthier shop environment.

Unlike some EVA formulations, PUR does not contain formaldehyde or other airborne toxins. And because PUR bonds via moisture rather than solvent evaporation, there are no solvent emissions.

It aligns with stricter safety and green manufacturing standards: choosing PUR shows a commitment to sustainability and worker safety.

2.6. Increased Productivity & Cost Efficiency

It may seem counterintuitive since PUR costs more per kilogram, but it often saves time and money in the long run. PUR cures faster to handling strength, which shortens cycle times. Workers can finish and deliver parts sooner.

Also, because PUR needs less adhesive per joint, suppliers report material cost savings. In practice, you might use 30–50% less PUR by weight than EVA for the same job.

In addition, the long-term reliability of PUR bonds means less rework, scrap or warranty issues – all of which improve overall profitability.

3. EVA vs. PUR Edge Banding: What’s the Difference?

EVA (Ethylene Vinyl Acetate) has been the industry standard hot-melt adhesive for decades. It’s inexpensive, fast-setting, and easy to work with. However, PUR adhesives represent an evolution in edge-banding technology. Here are the key differences:

3.1. Chemical Nature and Curing

Chemical Nature and Curing: EVA glue is a thermoplastic that bonds as it cools. Once set, it can be remelted if heated again (meaning joints can soften under heat).

In contrast, PUR is a thermoset – once it cures, it does not remelt. PUR cures through a chemical reaction with moisture, creating a permanent crosslinked bond. This makes PUR bonds structurally different and far more heat- and moisture-stable.

3.2. Bond Strength

Both adhesives yield strong initial adhesion, but PUR ultimately outperforms EVA. After full cure, PUR bonds tend to have higher peel and shear strength.

In practical terms, furniture manufacturers find that PUR-bonded edges rarely separate, even under stress.

EVA-bonded edges, while acceptable for many uses, are more prone to delamination in high-stress or high-moisture environments.

3.3. Glue Line Thickness and Appearance

To achieve strong bonding, EVA applications often deposit more adhesive, resulting in a visible glue line.

PUR’s superior strength allows for much thinner glue layers. The result is a nearly invisible seam – a big advantage on light-colored or transparent surfaces.

3.4. Application Temperature and Processing

EVA adhesives melt and apply at around 150–180 °C. PUR products typically heat to a similar or slightly lower range (about 120–150 °C).

However, EVA cooling is the main cure mechanism, whereas PUR’s bond strength builds over time. EVA sets almost immediately, meaning very short open times. PUR, by contrast, has a longer open time (minutes) and slower full cure (up to 24–48 hours).

This can affect throughput planning: EVA allows virtually instant press-off, but PUR provides some wiggle room to adjust alignment before final set.

3.5. Moisture and Heat Resistance

EVA bonds will degrade if exposed to steam, tropical humidity or high temperatures. PUR bonds improve with moisture exposure (within limits), as that is what completes their cure.

3.6. Environmental and Health Factors

Many EVA formulations contain small amounts of formaldehyde or VOCs. PUR generally emits virtually no formaldehyde and lower VOCs post-application.

For shops aiming at LEED certification or low-odor environments, PUR is often the preferred glue.

4. PUR vs Laser Edge Banding: Two High-End Options

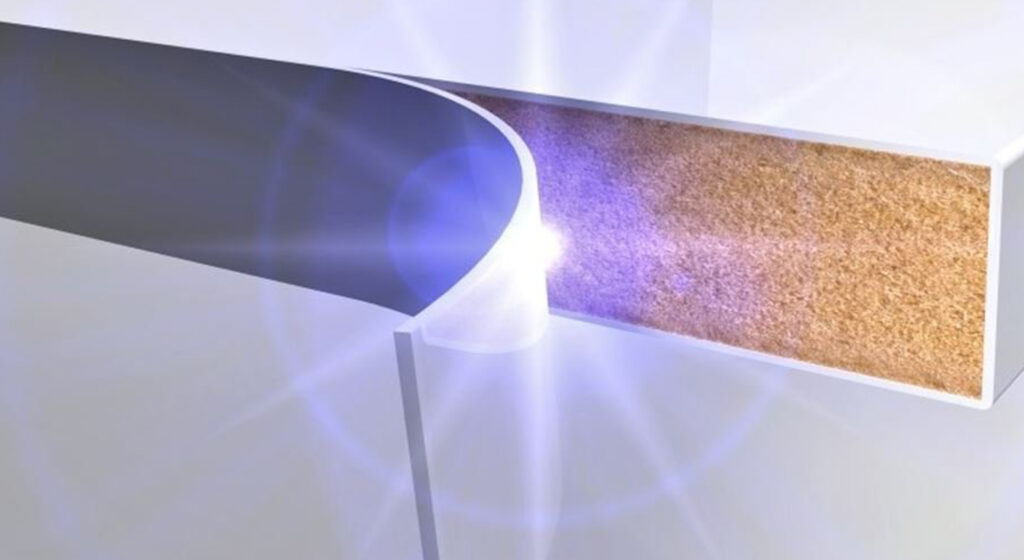

In recent years, Laser Edge Banding (sometimes called “laser bottom heat”) has emerged as an alternative to traditional glues. Laser edges use a special tape coated with a laser-reactive polymer and bond the edge with a laser diode instead of liquid glue. This technology promises completely seamless, glue-free edges. How does it compare to PUR?

4.1. Bonding Mechanism

Laser edge banding does not use adhesives at all. Instead, the laser beam melts the polymer on the tape, fusing it to the panel. PUR, by contrast, uses a reactive glue that cures over time. Both methods yield very strong joints, but the material origins differ (polymer tape vs liquid resin).

Laser edge banding does not use adhesives at all. Instead, the laser beam melts the polymer on the tape, fusing it to the panel. PUR, by contrast, uses a reactive glue that cures over time. Both methods yield very strong joints, but the material origins differ (polymer tape vs liquid resin).

4.2. Seamlessness and Aesthetics

Laser banding creates a flawless, invisible joint (“zero-joint” finish). There is no bead, so even on pristine white or translucent panels, the edge looks like one continuous piece. This is a key advantage over PUR (and especially EVA). Laser edge banding allows a permanent, completely seamless visual and functional bond resistant to moisture and heat.

In applications like high-gloss or acrylic cabinets, this perfect white-on-white or clear-on-clear finish can be worth the investment.

4.3. Speed and Cleanliness

Laser bonding is extremely fast and clean. There is no drying time or waiting – the bond is instantaneous as the panel passes under the laser. There are also no fumes or solvent emissions, and no cleaning of glue pots. Laser systems produce no volatile glue pollution, and require no cleanup, saving energy and maintenance

PUR systems, while much cleaner than solvent glues, still need occasional maintenance of the glue pot and can produce some odor during application.

4.4. Material Compatibility

Laser edge tapes must have the special polymer coating. You cannot use ordinary PVC/ABS tape – you need laser-compatible stock, which can be more expensive and currently available in fewer colors/finishes.

PUR, on the other hand, can bond any PVC, ABS, wood, acrylic or PVC foil tape. If you want to band with a thick solid wood or textured profile, PUR is more flexible.

4.5. Machine Cost and Complexity

Laser edge banding machines (or retrofit laser heads for existing machines) are significantly more expensive than standard PUR-capable banders. They also require precise calibration and maintenance of the laser system.

PUR glue stations, while requiring maintenance, are simpler and more established technology. For many shops, the decision comes down to budget and volume.

PUR banders are common and cost-effective; laser banders are premium investments for high-output or high-margin lines.

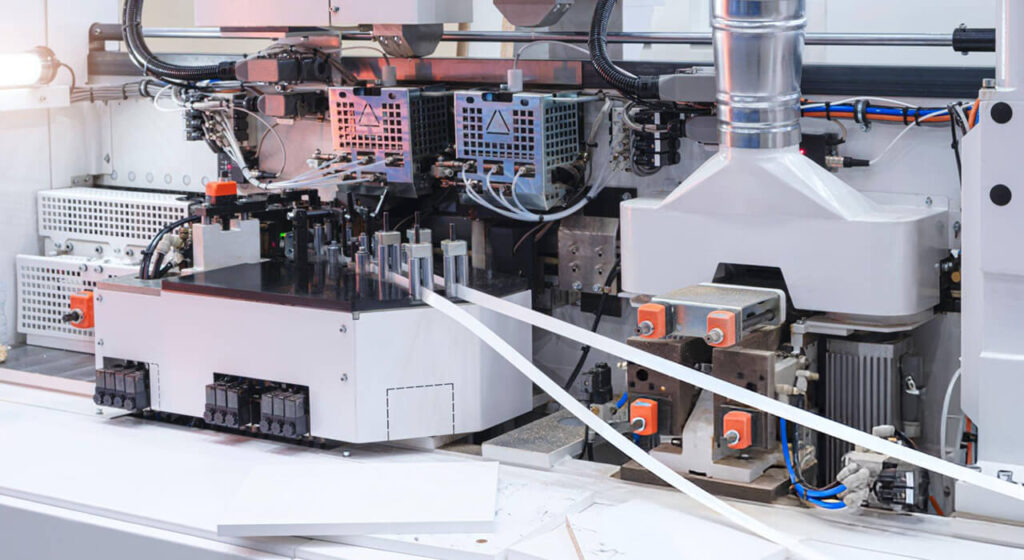

5. Application Process and Best Practices for PUR

To get the most out of PUR edge banding, careful attention to the application process is essential. Below are key steps and tips:

5.1. Machine Setup

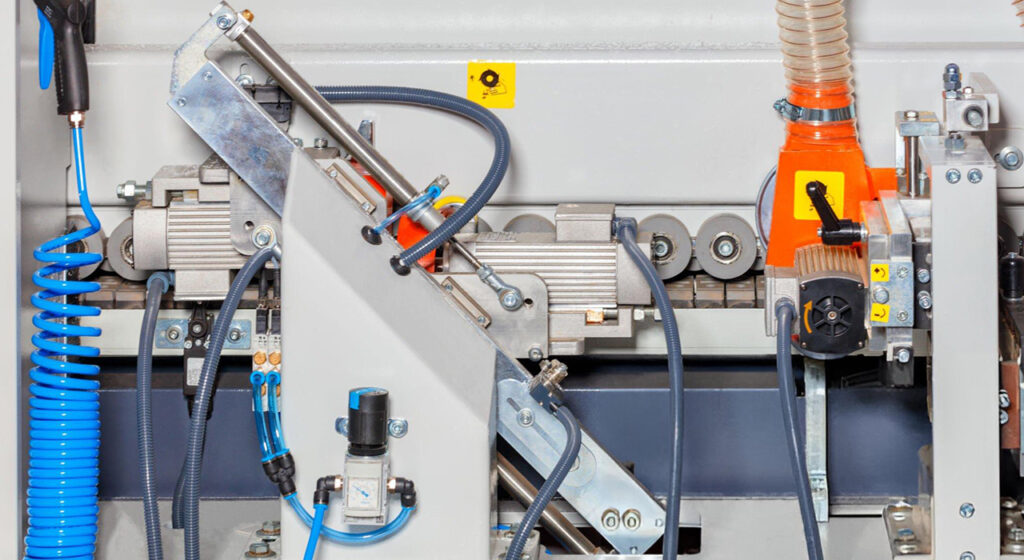

Ensure the edge bander’s PUR unit is clean, all filters (if any) are fresh, and the glue pot is properly heated. Most PUR adhesives apply best around 130–150 °C, though some formulations work as low as 120 °C. Set the temperature per adhesive spec.

Equip the machine with a nozzle or roller head suited for even spread. Verify that the pressure rollers are adjusted and in good condition.

5.2. Conditioning the Tape

PUR adhesives bond best if the tape adhesive and substrate have some surface moisture. Some manufacturers lightly mist water on natural wood edges to ensure complete curing.

However, too much moisture can cause foaming. Maintain the shop at normal humidity; extremely dry air can slow PUR cure, while very humid air accelerates it (sometimes within minutes).

5.3. Applying the Glue

As panels feed, the machine applies a thin bead or film of PUR onto the edge (or onto the tape, depending on design). Keep the glue pot full; avoid introducing air into the lines, as bubbles cause uneven glue flow.

5.4. Edge Banding

The tape is pressed onto the glued edge by pressure rollers immediately after glue application. Proper pressure (often pneumatic rollers) is critical for full contact. Since PUR cures chemically over time, you generally still trim and finish the edge as with EVA banding – the initial glue solidifies on cooling, allowing immediate trimming.

5.5. Curing

Immediately after press-off, the bond has initial strength due to cooling. Over the next hours, moisture in the air and board will complete the cure, making the joint irreversibly set.

Thus, parts can usually be stacked or processed, but full mechanical strength takes a day. Plan production so that newly banded parts are not subjected to extreme stress until cured.

5.6. Glue Changeovers

If switching between PUR and EVA, or between PUR formulations, be prepared to clean the system. Many of edge banding machines were equipped double-glue pot system. It can switch between PUR and EVA quickly.

On simpler machines, a small flush with cleaning granules or complete glue pot cleaning is needed. Always follow manufacturer guidelines – leftover glue can solidify and clog nozzles.

5.7.Trimming and Finishing

You can trim, flush, and profile the PUR-banded edges just like EVA edges – usually immediately on the same machine. In fact, many CNC edgebanders auto-trim the tape flush with a router, plane, and scraper.

Because PUR does not re-soften, finishing tools should be sharp to cut the cured PUR film cleanly. Be aware that fully cured PUR is harder than EVA, so if post-processing manually (e.g., hand scraper), use carbide blades.

6. Maintenance Tips for PUR Edgebanding

Maintaining PUR edge banding equipment ensures consistent quality and uptime. Follow these recommended practices:

6.1. Daily Cleaning

At the end of each shift, remove residual PUR from the glue pot and nozzles. While still warm (not scalding hot), scrape or wipe out as much cured glue as possible. Most machines allow you to dump the melt and flush with cleaning sticks or IPA-based solvents if needed. Emptying and cleaning the pot prevents old adhesive from charring or contaminating fresh glue

6.2. Vacuum Dust and Debris

Wood dust and scrap can jam the machine. Vacuum or blow out chips from the pressure rollers, trim saw, and feed track daily.

Dust buildup especially around the glue pot can act as insulation, causing overheating or lumpy glue application.

6.3. Roller and Blade Care

Keep trimming knives, planers, and scrapers sharp. Dull blades rub instead of cutting, and wood fragments can tear the edge joint. Similarly, inspect pressure rollers and feed rollers for nicks. A gouged roller can mar the part or apply uneven pressure on the PUR glue line.

6.4. Lubrication and Mechanics

Follow manufacturer schedules for lubricating chains, bearings, and pneumatic cylinders. A smoothly running machine maintains proper alignment. Over-lubricated parts can attract glue and dust – wipe off any excess.

6.5. Glue Pot and Nozzle Filters

Change any inline filters or screens regularly, as PUR can gel with resin particles. If your machine has a circulating oil or water heater system, ensure coolant is clean (some systems cool the glue tank).

6.6. Machine Calibration

Check that the glue pot temperature and application rate are correct. An infrared thermometer can verify pot temperature. Ensure emergency stops and sensors (like tape presence detectors) are functioning.

6.7. Preventive Service

Plan annual service on the heating elements, thermocouples, and pneumatic valves. PUR units operate under pressure; ensure seals and safety valves are intact to avoid dangerous leaks.

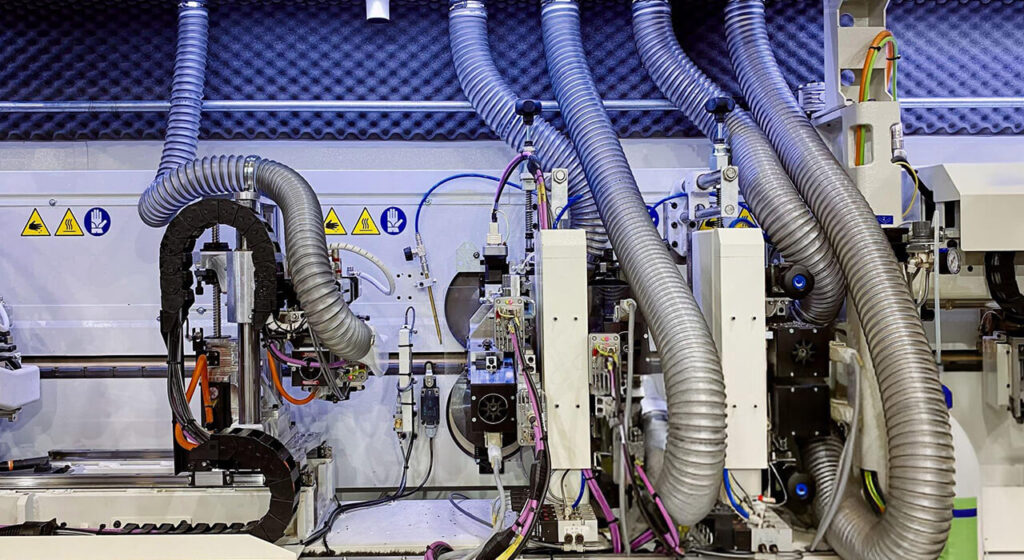

7. Recommended PUR Edge Banding Machines

Selecting the right edgebanding machine is critical for mastering PUR. Look for models that offer stable PUR heating, quick glue change systems, and robust pressure zones. Here are some industry-leading options:

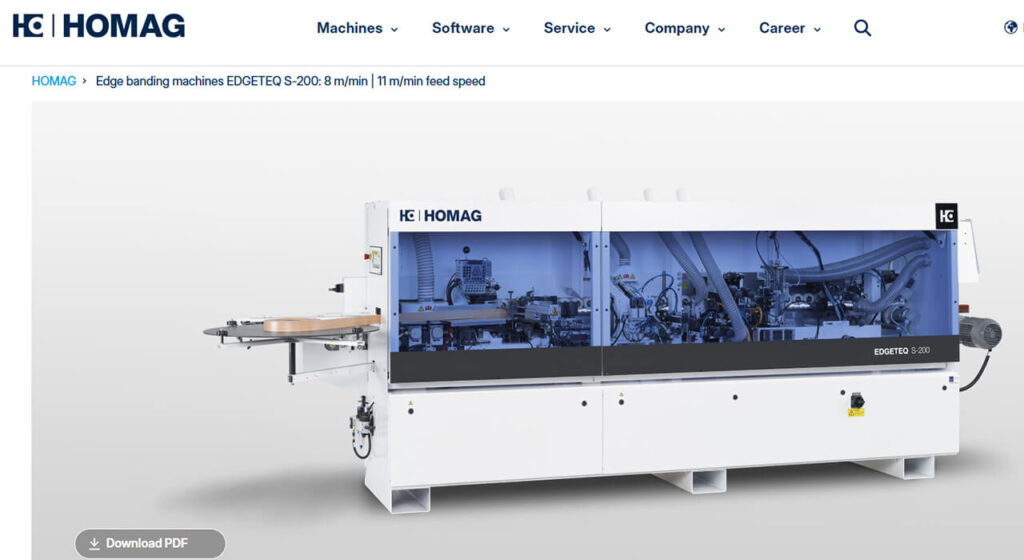

7.1. Homag EDGETEQ S-200

Homag is a market leader in edge banding. The EDGETEQ S-200 is a popular single-sided model that comes standard with a precision gluing unit for PUR. It feeds at 8–11 m/min and handles 6 mm edge thickness up to 60 mm panel height. Its SGP glue pot supports both EVA and PUR (Homag lists “processing of PUR-glue” as standard). The machine’s airTec option can even do zero-joint (laser-like) bonding.

In summary, the S-200 is an excellent entry to mid-range edgebander: compact, user-friendly, and capable of consistent PUR operation. (For details, see our Edge Banding Machines page.)

7.2. SCM Olimpic 500plus

This SCM Olimpic 500plus is engineered for EVA, PUR, and hot-air processes. SCM advertises that its SGP glue pot allows “use of EVA and PUR glue with simple and quick changeovers”. It has a hefty pressure zone and can run at 12–18 m/min – great for shops needing higher throughput. The Olimpic 500plus also supports machining of two radii and NC adjustments for fast switching between edge profiles.

In practice, its quick-glue-change design makes it ideal for jobs requiring frequent EVA↔PUR switches.

7.3. IMA Schelling Novimat Compact R3

IMA Schelling Novimat Compact R3 can be ordered for PUR gluing (with IMA’s quick-lock pot system). The R3 is capable of speeds up to 25 m/min, and as IMA notes, it “handles all aspects of edge processing” on an industrial scale. It features automatic pressure and feed controls for minimal operator effort. Notably, the R3 can be outfitted with an optional laser for zero-joint finishing, making it a hybrid machine.

This means you could run both laser edges and traditional PUR edges on one line. The R3 is ideal for shops that want top-tier performance in a compact footprint.

7.4. Biesse Akron Series

Biesse’s Akron edge banders (e.g. Akron 1400/1440) are robust and flexible. The newer Akron models offer a hybrid pre-melter (TM15) for rapid switching between EVA and PUR. They also come with features like Airforce top-sucking units that ensure perfect tape adhesion. For manufacturers requiring both types of adhesive glue, Akron banders are worth consideration. (Biesse provides extensive documentation on their Akron models.)

8. Additional Tips and Considerations

8.1. Adhesive Storage

Store PUR adhesive in airtight containers. Once a drum is opened, it will slowly absorb moisture and harden. Plan your inventory so an opened container is used up quickly. Keep spares sealed, especially in humid climates.

8.2. Health & Safety

Even though PUR is low-VOC, always ensure good ventilation in the banding area. Operators should avoid skin contact with hot adhesive. Many PUR melts appear neutral or off-white, but some formulations may be colored (black/pigmented for certain tapes) – treat all as irritants.

8.3. Training

Train operators on the differences of PUR: emphasize how it flows less than EVA (so clear blockages immediately), and how to clean up safely (mineral spirits are useless once PUR has cured). Many suppliers offer training for new PUR equipment – take advantage of this.

8.4. Environmental Compliance

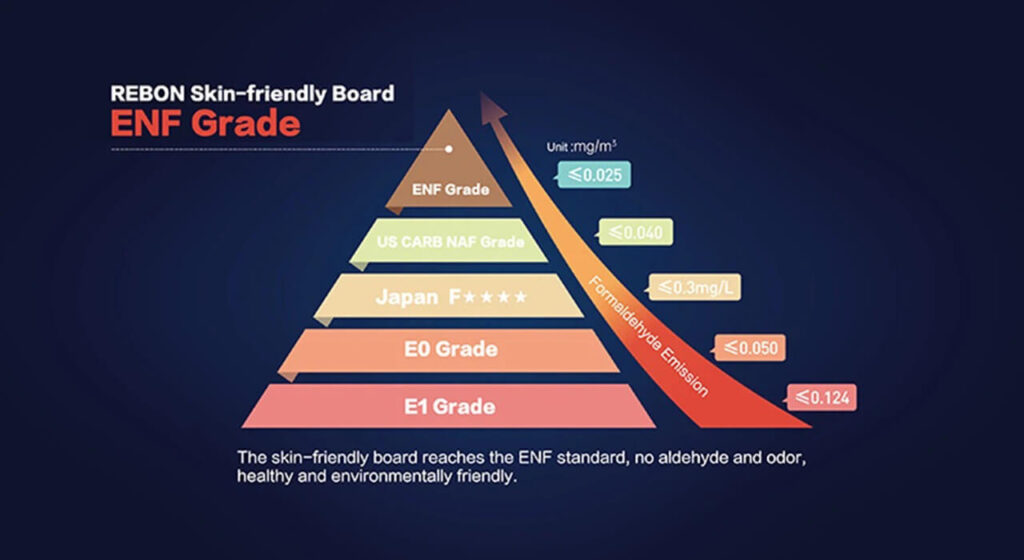

PUR usually meets or exceeds Formaldehyde Emission Standards (e.g. CARB, ETS, E0, etc.). Still, check specific grades if your project has formal regulations. UL and other agencies have approvals for PUR-banded products in some jurisdictions.

8.5. Part Design

When designing components, remember that PUR bonds strongly to all substrates. Sharp corner edges and voids can lead to glue sitting on shelf. A slight bevel or back-bevel on the edge profile can improve coverage.

Also, panels with heavy melamine paper edges bond well with PUR, but very porous substrates (like raw plywood edges) may require priming or an EVA intermediate coat to avoid moisture loss.

8.6. Cost Accounting

By paying attention to these details and trusting reputable equipment, your transition to PUR edge banding should yield immediately noticeable quality gains and long-term cost savings.

9. FAQ About PUR Edge Banding

What is PUR edge banding

PUR (Polyurethane Reactive) edge banding is a high-performance edge finish used to cover the exposed edges of panels (such as MDF, particleboard, or plywood).

Instead of being pre-glued with a hot-melt EVA (ethylene-vinyl acetate) adhesive on the back, PUR edge banding typically comes as a raw strip without adhesive.

During application, a PUR glue is applied separately from a heated glue pot. The panel edge and banding are joined under heat; the reactive polyurethane adhesive chemically cures, forming a very strong, moisture-resistant bond. Advantages of PUR edge banding include:

- Superior water and humidity resistance (ideal for kitchens, bathrooms, and commercial interiors)

- Higher heat resistance (less likely to peel under fluctuating temperatures)

- Better flexibility on tight radii without cracking

- Stronger bond strength, reducing the risk of edge lift over time

What are the three types of edge banding?

Edge banding materials are generally categorized into three main types based on their backing and adhesive system:

-

EVA (Ethylene-Vinyl Acetate) Pre-Glued Edge Banding:

-

Features a hot-melt EVA glue film already applied to the back of the strip.

-

The banding is applied using a hot-melt edge banding machine or iron to activate the adhesive.

-

Common, economical, and easy to use; suitable for most residential and light commercial applications.

-

-

PUR (Polyurethane Reactive) Edge Banding:

-

Un-glued banding paired with a separate PUR adhesive in liquid form.

-

Applied in an edge bander with a PUR glue pot; cured chemically (moisture-reactive).

-

Best for high-humidity environments, heavy-use cabinetry, and premium builds.

-

-

PSA (Pressure Sensitive Adhesive) Edge Banding:

-

Uses a pressure-sensitive (tacky) adhesive on the back.

-

No heat is required; the strip adheres by firm pressure alone.

-

Ideal for on-the-job repairs, field installations, or low-temperature environments where a hot-melt machine isn’t available.

-

Some sources also list ABS and PVC edge banding as sub-categories (materials of the strip itself), but overall there are three primary adhesive-based types: EVA (hot-melt), PUR (reactive), and PSA (pressure-sensitive).

What is the most durable edge banding?

Edge banding durability depends on both the strip material and the adhesive system. The most durable combinations include:

-

ABS (Acrylonitrile Butadiene Styrene) Edge Banding with PUR Adhesive:

-

ABS is more impact-resistant and heat-stable than PVC.

-

PUR glue provides superior water resistance and adhesion.

-

This combination resists scratches, yellowing, and delamination—ideal for commercial retail, healthcare, and hospitality furniture.

-

-

PVC (Polyvinyl Chloride) Edge Banding with PUR Adhesive:

-

While PVC can be more prone to color fading over time, it remains highly durable when paired with PUR glue.

-

PVC withstands moderate impact and is easy to clean, making it suitable for school or office environments.

-

-

Thick (2 mm–3 mm) Solid Wood Edge Banding with PUR:

-

Actual wood veneer or hardwood strips glued with PUR create a durable, premium finish.

-

More scratch-resistant and repairable than plastic banding, though installation costs are higher.

-

Between pure plastics, ABS + PUR is widely considered the “top tier” for durability, followed closely by PVC + PUR. If moisture resistance is paramount, PUR with non-porous ABS or high-pressure laminate (HPL) edging ensures the longest lifespan.

How do you smooth edge banding?

To achieve a perfectly smooth, seamless edge band after trimming:

-

Clean Residual Adhesive:

-

Use a soft cloth or scrubbing pad dampened with denatured alcohol (for EVA) or a PUR solvent (usually special cleaner) to remove any glue residue.

-

Make sure the banding is fully cooled before attempting to clean.

-

-

Fine Trimming & Buffing:

-

After the initial edge trim, gently run a fine roller or buffing pad along the joint to press the band firmly against the panel, eliminating any slight ridges.

-

-

Sanding or Filing:

-

For tiny overhangs or nibs, use a fine-grit abrasive pad (220–320 grit) or a flat file:

-

Lightly sand in a back-and-forth motion parallel to the band.

-

Keep the sander/foam block flat to avoid rounding over the corner.

-

-

A rubber sanding block wrapped in 320-grit sandpaper works well.

-

-

Edge Rounding (Optional):

-

If you want a slight bevel or radius on the edge, use a round-over bit in a trim router at low RPM. Follow with fine sanding to refine the profile.

-

-

Color‐Match Filler (If Needed):

-

Use a melt stick or colored edge band touch-up pen to fill minor dings or seams.

-

Once dry, buff lightly with 320–400 grit.

-

-

Final Wax or Polish:

-

Apply a thin coat of wax polish or edge band finish designed for PVC/ABS (sold by edge banding suppliers).

-

Buff with a soft cloth to achieve a uniform sheen.

-

By carefully trimming, cleaning, lightly sanding, and applying a finishing polish, you’ll end up with a smooth, factory-grade edge.

Can you remove edge banding?

Yes—you can remove most types of edge banding (EVA, PUR, PSA) with the proper technique:

-

Heat & Peel Method (EVA-Glued Banding):

-

Use a heat gun set to medium heat. Move the gun back and forth along the banded edge (kept about 4–6 inches away) until the adhesive softens.

-

Gently peel back the band using a putty knife or thin scraper, working in small sections to avoid damaging the panel.

-

Clean residual adhesive with denatured alcohol or an adhesive remover.

-

-

Cut & Pry Method (Veneer or Thick PVC/ABS):

-

Score along both top and bottom seams with a sharp utility knife to avoid tearing or leaving tear-out.

-

Slide a thin putty knife or scraper behind the banding, prying it off slowly while scoring any remaining glue filaments.

-

Remove any residual glue with a solvent (adhesive cleaner recommended by the band manufacturer) and a abrasive pad.

-

-

Chemical Solvent (PUR-Glued Banding):

-

PUR adhesive is more chemical-resistant, so use a specialized PUR cleaner (often containing solvents like methylene chloride).

-

Apply the cleaner, wait for the glue to soften, then use a scraper to remove banding and residual glue.

-

-

PSA Banding Removal:

-

For pressure-sensitive tape, use denatured alcohol or adhesive remover sprayed on the band.

-

Gently peel or scrape away. PSA leaves minimal residue compared to heat-activated adhesives.

-

Tips to prevent damage:

-

Always score the seams before prying to prevent chipping.

-

Work slowly over the entire edge—rushing can cause pitting in the panel surface.

-

Test solvents on a scrap piece first to ensure they won’t discolor the laminate.

-

After removal, sand lightly (320–400 grit) and fill any minor gouges before applying new banding.

Can edge banding be sanded?

Yes—but with caution. Whether using PVC, ABS, or veneer banding, you can sand the edge band to:

-

Smooth minor overhangs after trimming.

-

Blend seams between two banding pieces.

-

Refine profiles after using a round-over bit.

Guidelines for sanding edge banding:

-

Use Fine Grits Only (180–320): PVC and ABS can quickly burnish or melt under coarse abrasives. Start with 180–220 grit to remove high spots, then transition to 320 grit for a smooth finish.

-

Low Speed & Light Pressure: If using a random orbit sander, run it at the lowest speed setting and apply minimal pressure. Excess heat can melt plastic banding, causing glossy smears.

-

Hand Sanding for Control: A rubber block wrapped in 220–320 grit paper offers better control than power tools. Sand in one direction parallel to the edge to avoid rounding the corner too much.

-

Check Edges Frequently: Stop often to inspect the edge and prevent removing too much material.

-

Finish with a Soft Cloth: After sanding, wipe with a microfiber cloth to remove residue, then apply a plastic polish or vinyl finish product for optimal shine and protection.

While you can sand wood-veneer edging more aggressively (down to 100–120 grit) without melting, plastic banding always requires a gentle touch.

10. Conclusion

PUR edge banding has matured into a go-to solution for high-quality furniture and cabinet production. This guide has covered what PUR edge banding is, outstanding performance, and so on.

By investing in PUR technology, woodworking businesses can optimize their operations, improve the quality of their finished products, and stay ahead in a competitive industry.

By embracing PUR edge banding, woodworking manufacturers can deliver stunning, long-lasting cabinets and furniture.