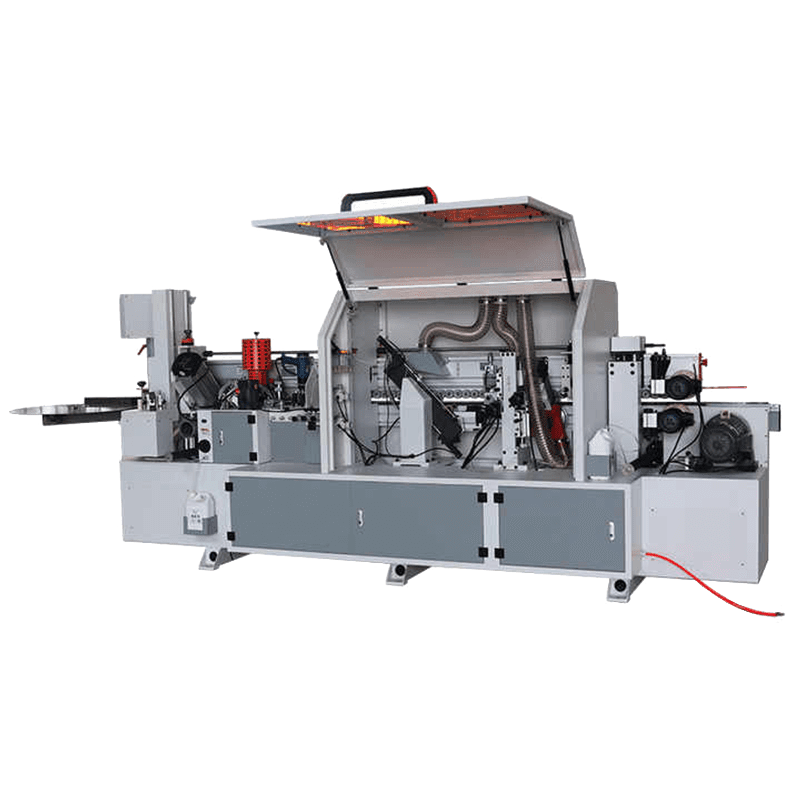

45 Degree Edge Banding Machine

45 Degree Edge Banding Machine

- 45-Degree Edge Banding

- Sharknose Finger-pull Handles

- Automatic Pre-Milling for Bevel Shapes

- Noise-Dampening Design

- Supports EVA and PUR Adhesives

45 Degree Edge Banding Machine

Bestin’s F350 45° edge banding machine is engineered for precise edge banding with bevel edge banding. 45-degree bevel pre-milling unit uses cutting-edge technology to deliver flawless results. It makes wood panels perfect and clean 45° bevels. Its automatic functions, upgraded glue system, and intuitive controls ensure high-quality finishes for woodworking professionals.

Benefits

- Automatic Pre-Milling for Bevel Shapes

Delivers precise, clean edges with perfect 45° bevel angles, ensuring high-quality panel finishes.

- Clever Bevel Cutting for a Clean Fold

Produces a seamless, clean fold where the vertical meets the bevel, improving the aesthetic quality of the panel.

- Pressure Roller Sets

Ensures the edge band is applied smoothly and evenly, enhancing adhesive contact and panel quality.

- Cleaning Devices for a Flawless Finish

Enhances the visual quality of the finished product, eliminating residue and ensuring a professional finish without manual cleaning.

Picture

Features

-

250mm Touch Screen Control

Large, user-friendly 250mm touch screen for controlling machine functions. Simplifies operation with intuitive controls and diagnostic tools, allowing for quick adjustments without technician assistance.

- Twin Shaping Heads for 45° Bevel

Heavy-duty twin shaping heads for cutting both vertical and 45° bevel profiles.

- End Saw Precision

End saws mounted on a cast iron base with high-precision guides. It can provide perfect end trimming, avoiding panel damage and delivering a clean, accurate finish.

- Upgraded Glue Pot (2600 ml)

Large glue pot capacity (2600 ml) with an automatic discharge. It can improve efficiency and provide a quick glue change at the press of a button.

- Supports EVA and PUR Adhesives

Compatible with both EVA and PUR glues. It can provide flexibility for different woodwork requirements, allowing you to switch between adhesives quickly and easily.

- Heating Devices for Stronger Bonding

Built-in heating units ensure the adhesive bonds firmly to the panel. Creates a durable and long-lasting bond, ensuring edges remain intact even after extended use.

- High-Speed Trimming with 12,000 RPM Motors

12,000 RPM HF motors for top and bottom trimming. It can guarantee ultra-fine trimming for perfectly smooth edges, improving the overall look and feel of the panel.

- Twin Scraping Unit

Twin scraping unit for precise edge scraping. It can remove glue to get a smooth, professional finish and enhance the final appearance of the edges.

- Final Spray and Polish

Pneumatic spray system and 1440 RPM buffing motors for final polishing. It can get the perfect edges, leaving a clean and professional look.

- Stable Air Pressure with 2-L Tank

Equipped with a 2L air tank to maintain stable air pressure during operation. Ensures smooth operation and consistent results.

Technical Data

| Model | F350 | | Power Supply Voltage | 380V/Three-Phase Four-Wire 50HZ |

| Total Power | 16kw | Air Source Pressure | 0.6-0.8Mpa | |

| Glue Pot Capacity | 2600ml | Glue Pot Temperature | 110°C-210°C | |

| Hot Melt Adhesive Type | PUR/EVA | Edge Banding Width | 14-40mm | |

| Plate Thickness | 14-25mm | Edge Banding Thickness | Usually 0.5-3mm (Related To Edge Banding Material) | |

| Slotting Height | 3-23mm | Feeding Speed | 12m/Min | |

| Sealing Plate Size | ≥250*150mm (250 Is The Size In The Edge Sealing Direction) | Straight Edge Height | ≥5mm | |

| Gas Tank Volume | 2L | External Vacuum Cleaner | Vacuum Nozzle ∮100mmx3 Pcs | |

| Type Of Edge Banding Material | PVC | Weight | 1330kg | |

| Packing Size | 450*110*164 (Length*Width*Height cm) | | |

Video&Brochures

We Are Here For You!

- +86 166 7861 1290

- Info@bestingroup.com

- www.bestingroup.com