Compact Edge Banding Machine With Premilling

Compact Edge Banding Machine With Premilling

- Versatile Function In One

- Compacted Design For Small Space

- Working Unit: Pre-Milling Glue —End Cutting —Fine Trimming —Scraping —Buffing

- Easy To Operate

- Size: 2850x536x1316mm

Compact Automatic Edge Banding Machine

Elevate your woodworking production with the BESTIN Compact Edge Banding Machine With Premilling.

Designed as an entry-level, high-performance automatic edgebander, this machine is the perfect blend of quality and affordability for small workshops and cabinet makers.

Its integrated pre-milling unit, combined with advanced trimming, scraping, and buffing functions, ensures every panel receives a flawless edge finish.

Benefits

- Optimum Edge Quality

The dual counter-rotating diamond cutterheads pre-mill each panel, creating a perfectly straight edge before glue application. This ensures maximum adhesion and a superior final product.

- Enhanced Productivity

With fully automatic functions including edge feeding, end trimming, flush trimming, and PVC scraping, production becomes faster and more consistent. The chain feed system guarantees steady, scratch-free material handling

- User-Friendly Operation:

Featuring a PLC control system an optional touchscreen interface, adjustments are quick and precise. Change edge tape thickness effortlessly between 0.4mm and 3mm, ensuring versatility across projects

- Space-Saving Design

The compact design is ideal for small workshops, delivering industrial-level performance without requiring excessive floor space.

Picture

Features

- Pre-Milling Unit

Equipped with two counter-rotating diamond cutterheads, the pre-milling unit ensures the panel edge is flawlessly prepared for optimal glue penetration and tape adhesion.

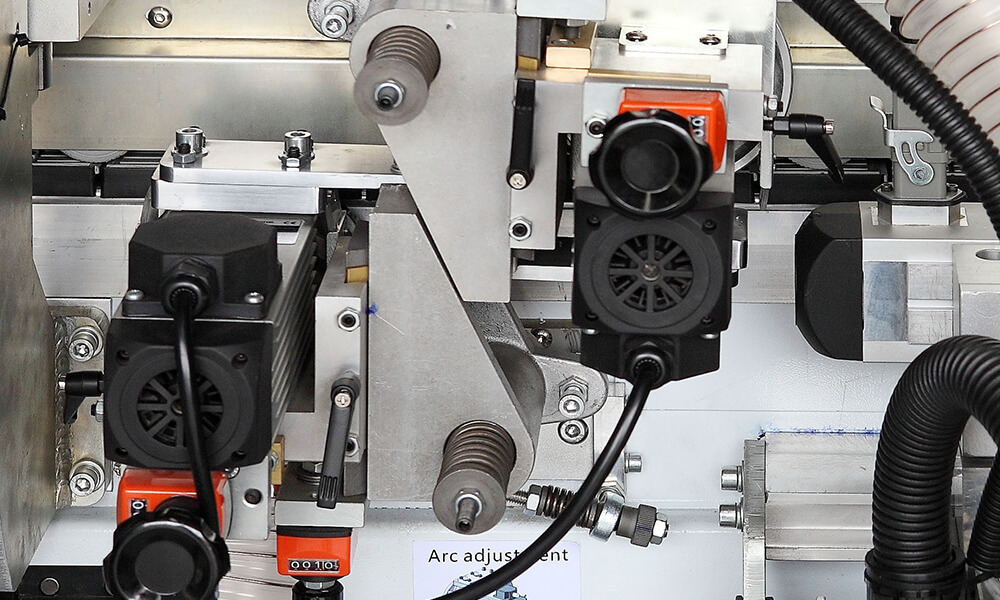

- End Trimming

An 8800 RPM dual saw blade and 10500 RPM top & bottom trimmers (with insert knife cutters) provide clean, precise cuts. Quickly switch from flush to bevel and radius trimming for a tailored finish.

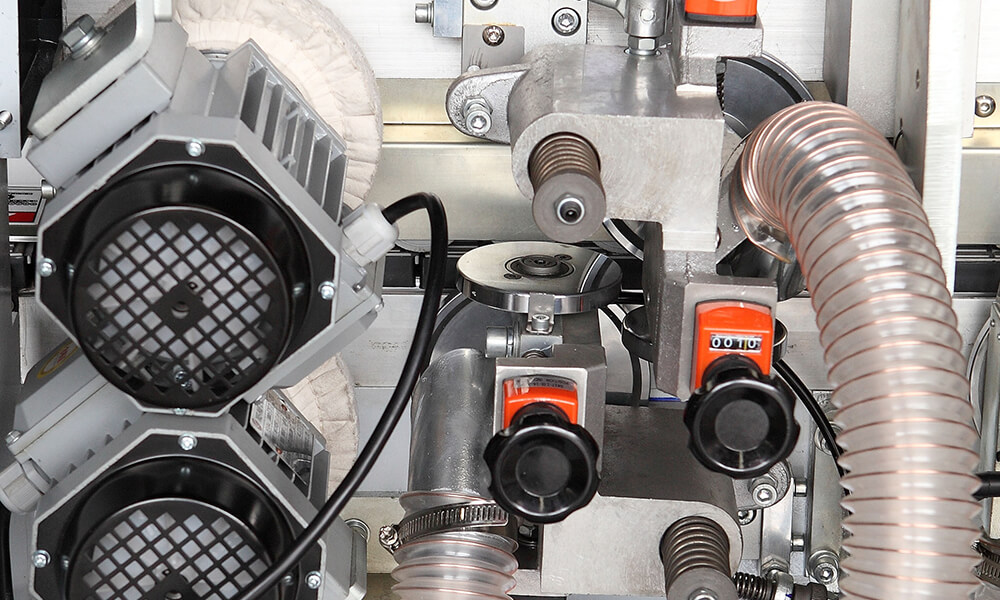

- Advanced PVC Scraping & Buffing

The radius scraping unit fine-tunes the edge while removing excess glue. Follow this with the 2800 RPM buffing units that polish ABS and PVC edges, erasing discoloration and enhancing visual appeal.

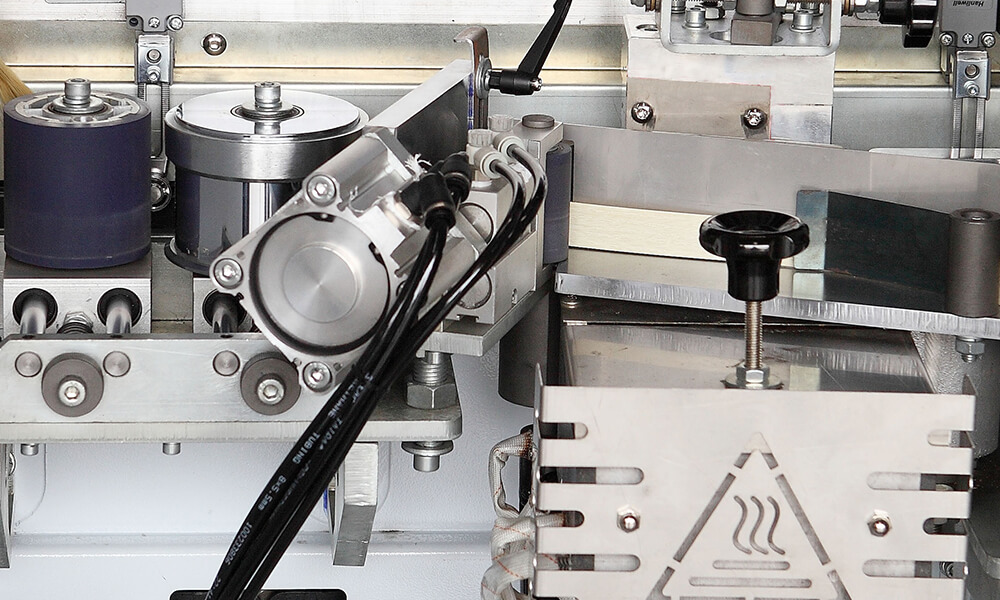

- Efficient Glue Application

The 1.2kg Teflon-coated hot-melt glue pot, paired with an adjustable glue roller, ensures even and reliable glue distribution for strong, lasting bonds.

- Robust and Reliable Mechanics

A heavy-duty chain feeder and a spring-loaded pressure system (with dual pressure rollers – chrome and rubber) provide consistent workpiece feeding and pressure, ensuring flawless edge results every time.

- Heated Infeed Fence

Pre-heats panels for optimal glue penetration, contributing to the durability and quality of the edge banding.

Technical Data

|

F600 |

|

|

Total

Power |

10.9KW |

|

Overall

Dimensions |

2850x536x1316mm |

|

Feed

Speed |

9m/Min |

|

Edge

Thickness |

0.4-3mm |

|

Panel

Thickness |

10-50mm |

|

Panel

Length |

≥150mm |

|

Panel

Width |

≥120mm |

|

Working

Air Pressure |

≥0.6Mpa |

|

Weight |

620KG |

Video&Brochures

We Are Here For You!

- +86 166 7861 1290

- Info@bestingroup.com

- www.bestingroup.com