As a woodworking enthusiast or professional, you understand the importance of precision and quality in every project.

Achieving smooth, flawless edges is a critical step in crafting furniture, cabinetry, or any wooden masterpiece.

That’s where the best edge sander comes into play—a must-have Sanding Machine designed to streamline your sanding process and elevate your craftsmanship.

At Bestin Company, we’re committed to helping you find the perfect edge sanding machine for your workshop, whether you’re a hobbyist or running an industrial operation.

In this guide, we’ll introduce you to the best edge sanders from leading brands, including our very own Bestin 60DS Side Sander, alongside competitors like Powermatic, Cantek, and JET. Expect detailed comparisons, expert insights, and actionable advice.

Ready to transform your woodworking game? Let’s dive in and explore the world of edge sanders, ensuring you find the ideal machine to meet your needs.

Featured Resource

Table of Contents

1.What is an Edge Sander?

An Edge Sander is a specialized woodworking machine designed to sand the edges of wooden pieces with precision and efficiency.

Unlike handheld sanders, edge sanders are stationary machines featuring a continuous sanding belt that rotates around rollers. This belt, allows you to guide your workpiece along a stable table, ensuring consistent results every time.

1.1. How Edge Sanders Work

The core of an edge sander is its sanding belt—a loop of abrasive material that spins at high speeds. You position your workpiece against the moving belt, which removes material to smooth and refine the edge.

Many models, known as oscillating edge sanders, add an up-and-down motion to the belt’s rotation. This oscillation reduces heat buildup, prevents wood burning, and extends belt life by evenly distributing wear.

1.2. Types of Edge Sanders

Edge sanders come in various forms to suit different needs:

- Oscillating Edge Sanders: Feature a belt that oscillates vertically, delivering smoother finishes and longer belt life. Ideal for most woodworking tasks.

- Benchtop Edge Sanders: Compact and portable, perfect for small workshops or hobbyists with limited space.

- Industrial Edge Sanders: Heavy-duty machines with powerful motors and large tables, built for high-volume production.

- Combination Sanders: Multi-functional units combining edge sanding with disc or spindle sanding capabilities.

Understanding these types helps you pinpoint the best edge sanding machine for your specific projects.

2.Why You Need the Best Edge Sander for Woodworking

Investing in a top-tier edge sanding machine for woodworking offers unmatched benefits:

- Precision: Achieve uniform edges that enhance the aesthetic and functional quality of your work.

- Efficiency: Save time and effort compared to manual sanding, especially on large or repetitive projects.

- Versatility: Handle straight edges, curves, and contours with ease, depending on the model.

- Professional Results: Elevate your craftsmanship to meet client expectations or personal standards.

Whether you’re sanding plywood edges, shaping cabinet doors, or finishing intricate furniture pieces, the right edge sander is a game-changer.

3.Factors to Consider When Choosing the Best Edge Sander

3.1. Motor Power

Measured in horsepower (HP), motor power determines the sander’s ability to handle tough materials. Hobbyists may need 1-1.5 HP, while professionals might opt for 2-3 HP or more.

3.2. Belt Size and Speed

Larger belts (e.g., 9” x 138”) accommodate bigger workpieces, while adjustable speeds (in feet per minute, FPM) offer flexibility for various tasks.

3.3. Oscillation Features

3.4. Table Size and Adjustability

3.5. Dust Collection

3.6. Build Quality and Durability

3.7. Price and Value

Balance your budget with the features you need. A higher upfront cost can mean better performance and fewer repairs down the line.

By weighing these factors, you’ll find an edge sanding machine that perfectly suits your workshop.

4.Top 10 Best Edge Sanders for Woodworking: Brands and Models Compared

After analyzing the market and top-ranking content, we’ve curated a list of the best edge sanders from 10 leading brands.

4.1. Bestin 60DS Side Sander

Overview:

The Bestin 60DS edge sander is engineered specifically for the grinding and sanding of the edges of plywood, MDF, veneer, and solid wood materials. Designed for efficiency, this model features an adjustable roller speed controlled via inverter technology, ensuring optimal performance across various wood hardness levels.

Key Features:

- Adjustable Roller Speed: Precisely control the roller speed to match material hardness.

- High-Quality Sandpaper: Uses imported Riken sandpaper, offering durability with grit options from 80 to 600.

- User-Centric Design: An easy-change system for sandpaper and customizable appearance options.

- Powerful & Stable: Provides consistent sanding with electric-controlled lifting systems and robust conveyor motors.

Why Choose Bestin 60DS?

- Ideal for precision side sanding that minimizes material wastage.

- Built with user experience in mind—ensuring both ease of operation and repeatable, high-quality results.

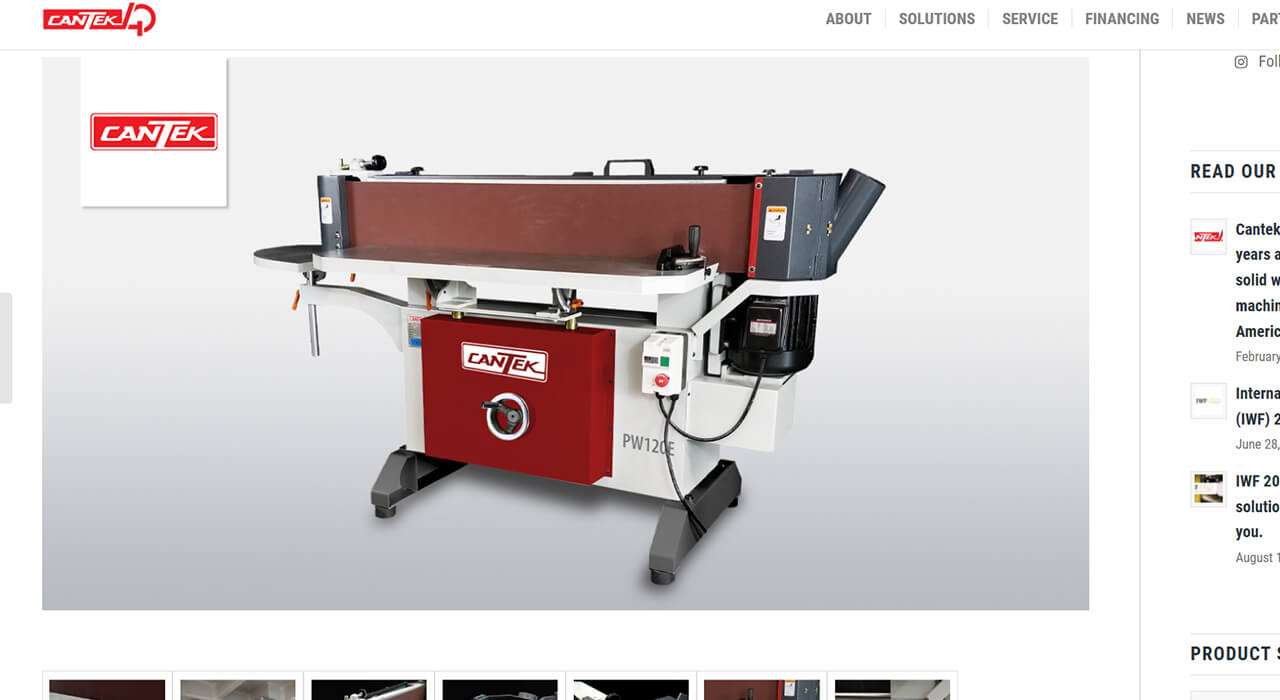

4.2. CANTEK PW120E Oscillating Edge Sander

Overview:

The CANTEK PW120E is a high-performance oscillating edge sander featuring a powerful 3HP motor perfect for demanding industrial applications. Its robust design includes cast aluminum tables that can be tilted for both straight and miter edge sanding.

Key Features:

- Oscillating Belt Technology: Enhanced belt life due to running cooler during operations.

- Adjustable Tables: Front and rear tables are adjustable and tiltable to accommodate different angles.

- Large Sanding Platen: A 9.5″ x 48″ cast iron platen ensures stability, especially when sanding longer workpieces.

- Built-in Dust Collection: Dual 4″ dust chutes for connecting to dust collectors guarantee a cleaner work environment.

Unique Benefits:

- Ensures optimal sanding quality on a wide range of materials.

- Extended sanding belt life reduces maintenance and replacement costs.

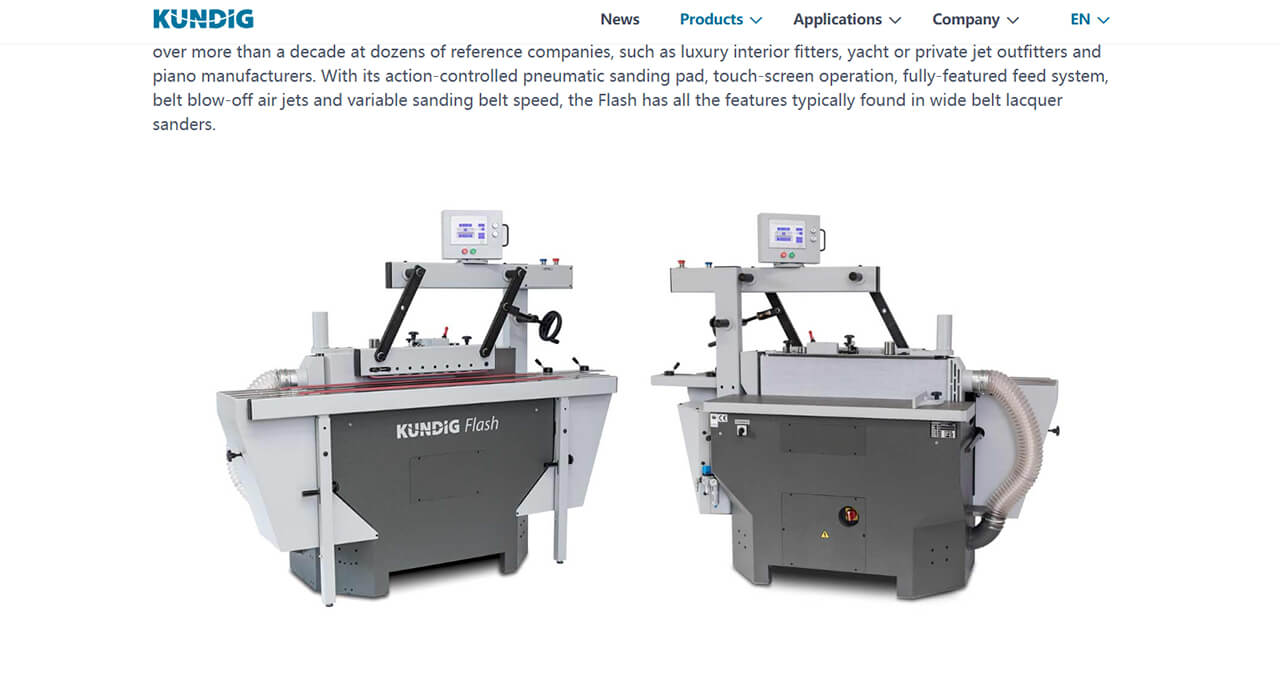

4.3. Kündig Flash – The Lacquer Edge Sanding Specialist

Overview:

The Kündig Flash stands out in the market with its groundbreaking technology specifically tailored for high-gloss lacquer edge sanding. Trusted by luxury interior fitters, yacht and private jet outfitters, and piano manufacturers, this machine is a hallmark of precision and quality.Key Features:

-

Touch Screen Operation: Rotatable 270° for intuitive sanding program adjustments.

-

Pneumatic Sanding Pad: Prevents sanding through thin lacquer layers by offering precision insertion and removal timing.

-

Air Jet Belt Blow-Off: Actively prevents heat build-up and belt clogging, ensuring long belt life.

-

Variable Belt Speed: Stepless speed adjustment guarantees perfect sanding on even the most delicate surfaces.

Unique Benefits:

-

Perfect for demanding high-gloss applications where over-sanding can ruin premium finishes.

-

The innovative design provides supreme control over sanding depth and precision.

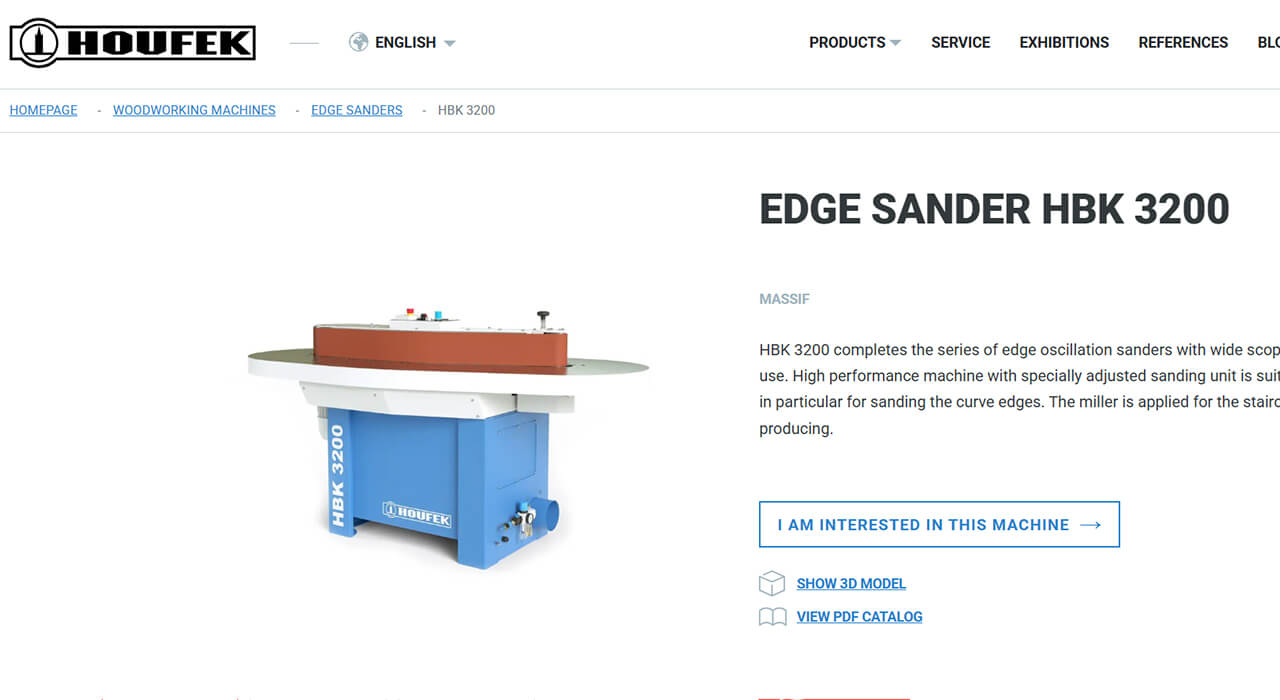

4.4. HBK 3200 – The Multipurpose Edge Sander

Overview:

The HBK 3200 is a robust and multipurpose edge sander designed for sanding both flat and curved edges. It is particularly well-suited for sanding staircases, furniture parts, and other custom woodwork.

Key Features:

-

Large Sanding Belt: 150 mm width and 3200 mm length, making it ideal for extensive workpieces.

-

High Speed & Efficiency: Operates at a remarkable 15 m/min while maintaining consistent finish quality.

-

Heavy-Duty Build: Weighing 680 kg, it is stable and reliable in heavy industrial usage.

-

Flexible Operation: Accommodates both single- and double-sided sanding operations.

Unique Benefits:

-

Comprehensive capability to handle the sanding of perpendicular, rounded, and radius edges.

-

Its multipurpose design improves production efficiency in busy workshops.

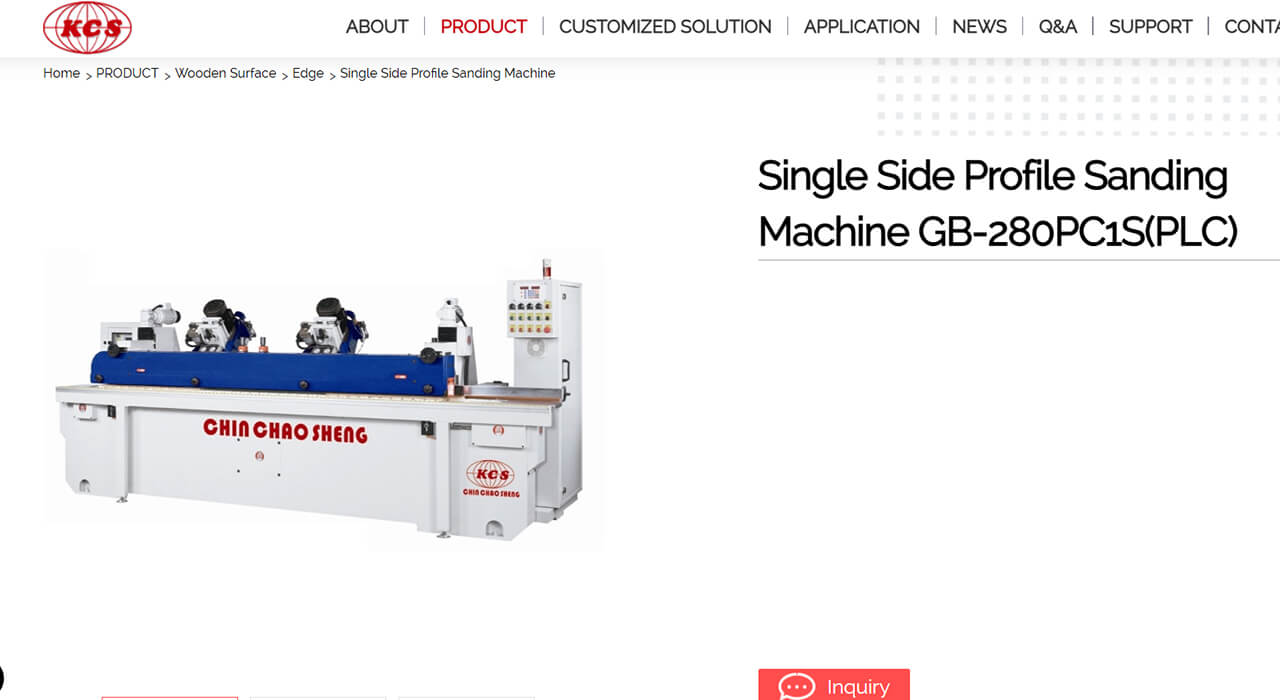

4.5. Single Side Profile Sanding Machine GB-280PC1S

Overview:

The GB-280PC1S is designed to provide industrial-level edge sanding with precision and ease of use. Its triangular belt head design features oscillation and air jet cleaning to maintain optimal sanding quality even under rigorous conditions.Key Features:

-

Triangular Belt Head: Offers versatile sanding angles with a tilt range from -90° to +20°.

-

PLC Controlled: Fast and efficient maintenance with an intuitive PLC control system.

-

Quick Maintenance: All motors and reducers are manufactured to ISO standards ensuring consistent performance.

-

Sturdy Frame Construction: Welded from thick gauge steel plates for maximum durability and accuracy.

Unique Benefits:

-

High speed and variable adjustment settings allow tailoring for a wide range of projects.

-

Perfect for both fine detail work and large-scale industrial sanding.

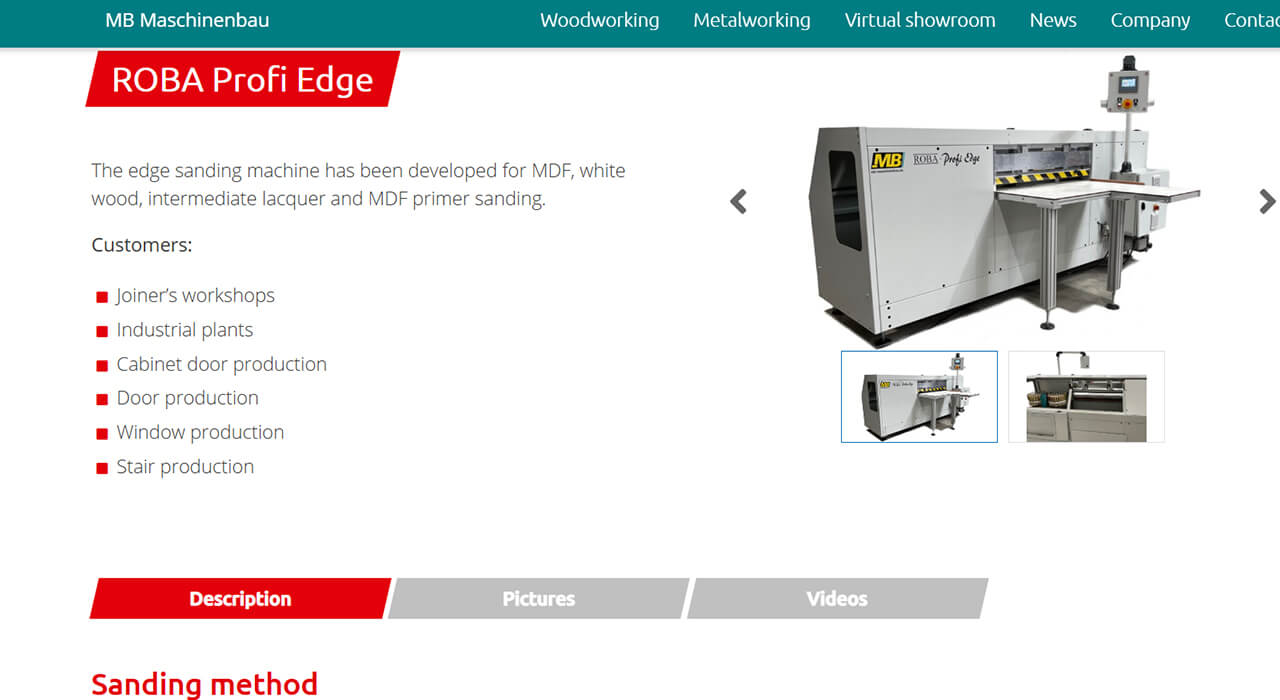

4.6. OBA Profi Edge – Precision for Profiled Edges

Overview:

The OBA Profi Edge is built for sanding profiled edges and panels, especially for high-production environments such as joiner’s workshops, cabinet, door, window, and stair production facilities.Key Features:

-

MB Double Brush Unit: Maximizes contact between sanding tool and workpiece, ensuring a uniform finish.

-

Pneumatic Pressure Bar: Secures workpieces without excessive manual repositioning.

-

Dual-Directional Rotation: Tools rotate in both directions to optimally sand end-grain areas.

-

Dust-Free Operation: An encapsulated design and effective dust extraction system reduce mess and improve air quality.

Unique Benefits:

-

Greatly enhances production efficiency in industrial settings.

-

The integrated system adapts to various workpiece sizes and shapes.

4.7. L-700TB2 Triangle Track Belt Profile Edge Sanding Machine

Overview:

The L-700TB2 is designed with a revolutionary track belt sanding head that provides exceptional detail and control. Ideal for polishing complicated and irregular wood edges, it’s perfect for small-batch or detail-oriented production.Key Features:

-

Track Belt Design: The sanding head can be manually adjusted in various directions, including tilt adjustments from 0° to 90°.

-

Precision Micro Adjustment: An attached mechanical meter gauge allows for detailed micro-adjustments.

-

Piano Rubber Pressing Rollers: These rollers provide stable pressure to secure wood panels, reducing waste and ensuring consistent quality.

-

Variable Speed Inverter Control: Both the feeding and sanding speeds are adjustable for best results on any wood type.

Unique Benefits:

-

Perfect for high-efficiency polishing and detail work.

-

Provides flexibility for irregular and custom woodworking projects.

4.8. RITTER R701/R703 – The Universal Edge Belt Sander

Overview:

RITTER’s R701/R703 series is highly regarded in the woodworking industry for its reliability and versatility. These machines are designed for multiple edge finishing applications in furniture and custom woodworking.Key Features:

-

Double-Sided Ground Steel Platen: Provides stability and ensures a smooth finish.

-

Bias Tilting Tables: Allow sanding on both sides for added versatility.

-

Full Dust Hood: Helps to maintain a clean and safe work environment with multiple dust collection ports.

-

Dual Motor Options: Available in 1.5 HP and 2 HP configurations to suit varying production needs.

Unique Benefits:

-

Provides excellent sanding accuracy even on tough or irregular surfaces.

-

The robust design minimizes downtime with easy maintenance and setup.

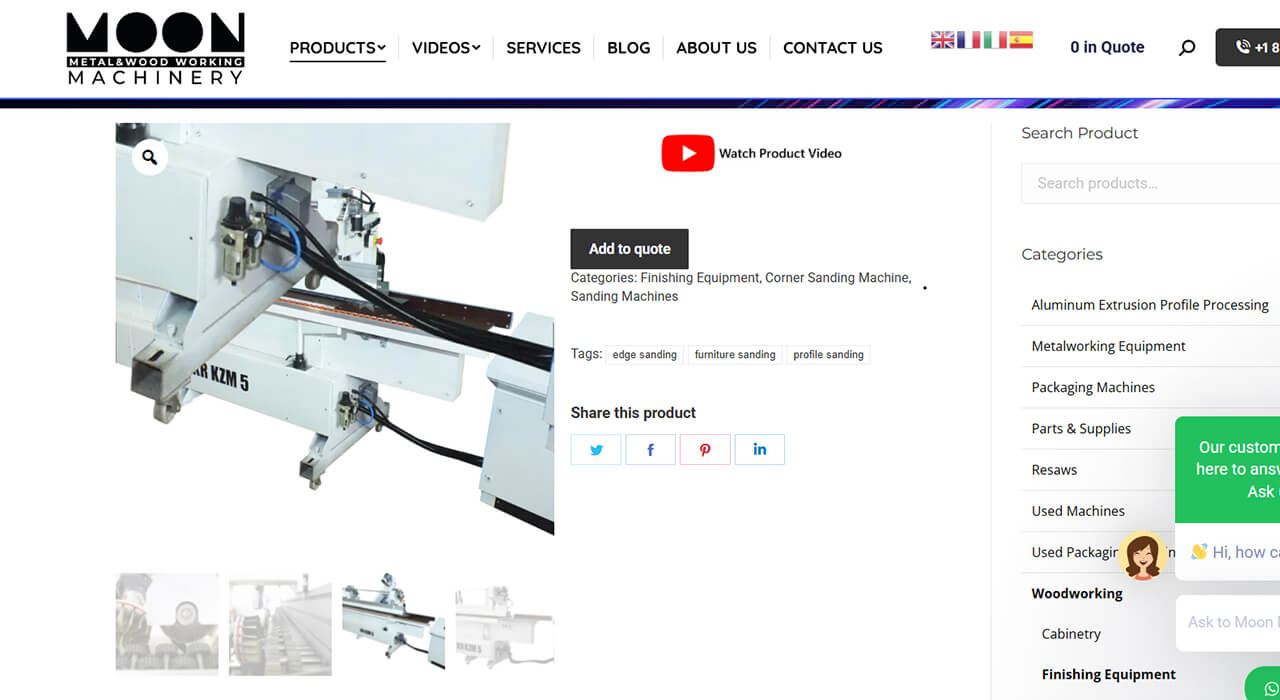

4.9. KR KZM 5 – The Edge Sander for Modular Furniture Parts

Overview:

Produced by Moon Machine, the KR KZM 5 is tailored for sanding door edges, cabinet door edges, and modular furniture components. Its flexible, oscillating sanding unit means it can handle both flat and curved edges with ease.

Key Features:

-

Oscillating Operation: Reduces the need for manual adjustments and extends sanding belt life.

-

Adjustable Belt Sanding Unit: Modify angle, distance, and pressure intensity to suit different materials.

-

Easy Sanding Change Feature: Quick change of sanding belts and accessories cuts downtime.

-

Ergonomic Design: Optimized for user comfort and rapid setup, improving overall productivity.

Unique Benefits:

-

Ideal for both raw edge sanding and primer sanding.

-

Economical in operation while producing high-quality finishes.

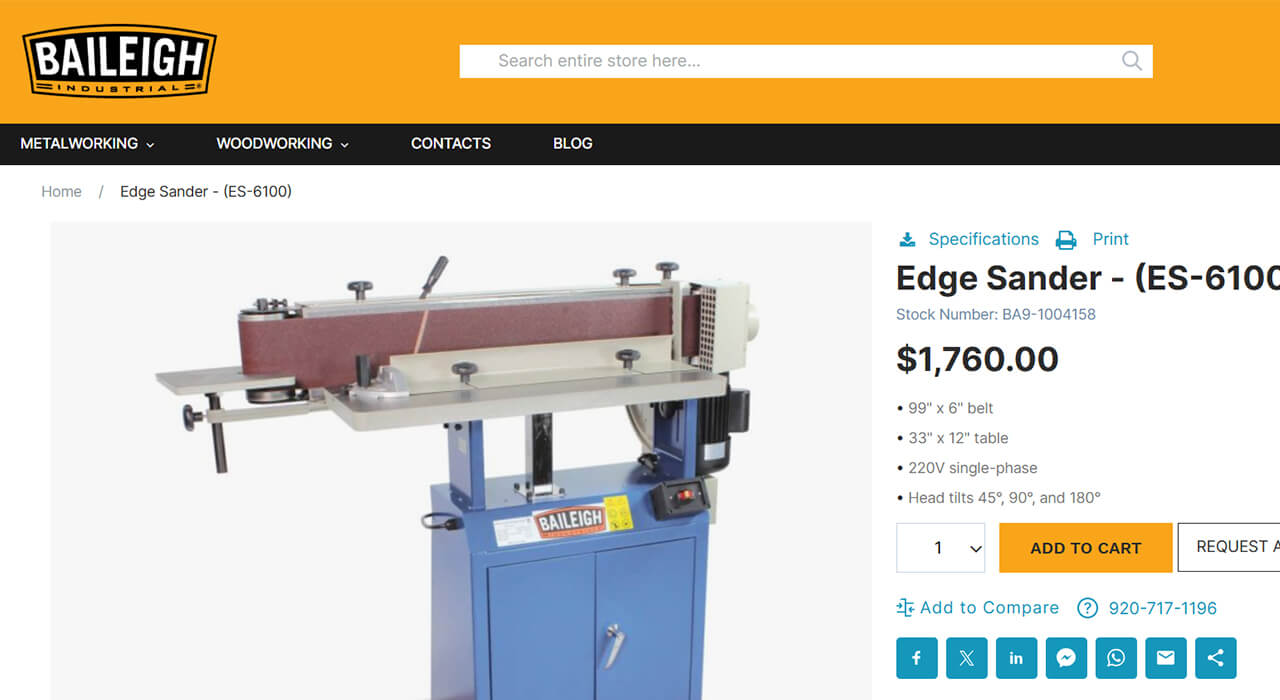

4.10. Baileigh ES-6100 Edge Sander

Overview:

Key Features:

-

Precision Engineering: Outstanding accuracy even when working with delicate wood surfaces.

-

User-Friendly Controls: Intuitive interfaces and robust controls make it accessible to operators at all levels.

-

Multiple Configuration Options: Available with variable belt speeds, oscillation functions, and customizable table settings.

-

Enhanced Dust Collection: Designed to keep the work area clean and maintain air quality.

Unique Benefits:

-

Trusted by professionals worldwide for reliability and innovation.

-

Integrates seamlessly into both small workshops and large production lines.

5. How to Use an Edge Sander Effectively

5.1. Preparation

- Choose the right sandpaper grit: 80-120 for rough sanding, 180-220 for finishing.

- Secure your workpiece to prevent shifting.

5.2. Adjusting the Machine

- Set the table height and angle to align with your sanding needs.

- For oscillating models, adjust the oscillation rate as desired.

5.3. Sanding Technique

- Feed the workpiece against the belt’s rotation for optimal material removal.

- Apply steady, even pressure—let the machine do the heavy lifting.

5.4. Safety Tips

- Wear safety gear: glasses, dust mask, and hearing protection.

- Keep hands clear of moving parts and ensure proper machine grounding.

6. Maintenance and Care for Your Edge Sander

Keep your best edge sanding machine in peak condition with these maintenance practices:

- Cleaning: Remove dust from tables and rollers after each use. Use compressed air for tight spots.

- Belt Care: Replace worn belts and ensure proper tracking and tension.

- Lubrication: Follow manufacturer guidelines to lubricate bearings and moving parts.

- Inspection: Check electrical components and alignment regularly.

Proper care ensures longevity and consistent performance, saving you time and money.

7. Conclusion: Find Your Perfect Edge Sander Today

Choosing the best edge sander is about matching your woodworking ambitions with the right machine.

From the industrial might of the L-700TB2 to the budget-friendly Delta 31-482, and our own Bestin 60DS for panel perfection, there’s a machine for every need.

Consider your project scale, budget, and workshop space to make the best choice.

Ready to elevate your craft? Explore our full range of edge sanding machines and see why Bestin Company is a leader in woodworking innovation.

Don’t wait— for expert advice or to order your Bestin 60DS and experience sanding perfection firsthand!