Edge Banding is an essential finishing technique in woodworking. It can make the wood panel look polished to raw edges and enhance the workpiece’s durability.

Whether crafting custom furniture or working on cabinetry, the edge banding‘s quality can significantly impact the final product.

If you want to get a beautiful edge banding, it is important to choose the right portable edge bander.

In this article, we’ll explore what makes a best portable edge bander for various woodworking projects, guiding you in getting the right Portable Edge Banding Machine.

Table of Contents

1. What is a Portable Edge Bander?

A portable edge bander is a compact, handheld or benchtop machine designed to apply adhesive and edging material—commonly PVC, ABS, wood veneer, or melamine—to raw panel edges. Unlike stationary industrial edge banders, these portable units:

- Use small glue pots (EVA or PUR hot-melt glue) or hot-air systems for pre-glued tape

- Offer temperatures ranging from 100 °C to 210 °C for optimal adhesion

- Support edge widths typically from 0.4 mm up to 65 mm (and in specialty models, up to 260 mm)

- Feature manual or automated trimming attachments to remove excess tape

- Weigh between 2.7 kg to 52 kg, making them suitable for job-site use or tight workshops

Portable edge banders free you from floor-standing conveyors while delivering near-factory quality on doors, panels, and custom pieces.

2. What Should You Consider When You Buy A Portable Edge Bander?

When buying a portable edge bander, there are some factors you should consider:

2.1. Glue Type

Most machines use EVA glue, which is fast and affordable. Some models support PUR glue, which offers higher water and heat resistance. Others may use pre-glued edge tapes, which require less cleaning and no glue pot.

2.2. Edge Tape Compatibility

Check what tape types the machine supports: PVC, ABS, melamine, or wood veneer? Also, look at the maximum edge thickness and width it can handle.

2.3. Temperature Control

Precise temperature control is essential for consistent gluing. Look for models with digital thermostats or adjustable dials to match different glue types and materials.

2.4. Feed Speed

Faster feed speeds help in high-volume tasks. However, for curved or small pieces, a slower, controlled feed may offer better results.

2.5. Portability and Weight

A portable edge bander’s advantage is its mobility. It is important to make a machine lightweight. A lightweight machine makes it easier to transport and use in different locations.

3. Portable Edge Bander’s Advantages

Portable edge banders offer several advantages, making them a popular choice for many woodworkers:

3.1. Versatility in Various Work Places

Whether in a small workshop or on a construction site, a portable edge bander adapts to different settings, providing flexibility that stationary models cannot match.

3.2. Space-Saving Benefits

For woodworkers with limited shop space, a portable model can be stored away when not in use, freeing up valuable work areas.

3.3. Cost-Effectiveness

Portable edge banders are generally more affordable. It can offer an economical option without sacrificing quality.

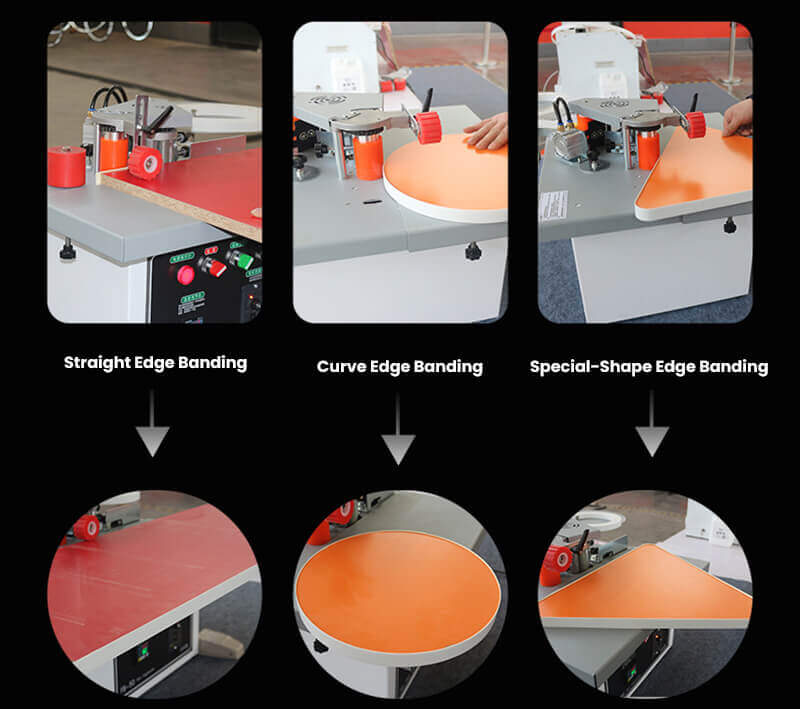

3.4. Working On Multiple-shaped Wood Boards

The portable edge bander can be used on multiple-shaped wood boards, including straight, curved, or irregularly shaped edges.

4. Top Portable Edge Bander Brands

There are some portable edge banding machine brands, you can choose from them.

4.1. Festool Conturo KA 65

The Festool Conturo KA 65 is a premium hand-held edgebander ideal for curved or on-site work. It uses EVA hot-melt glue cartridges (no messy pots) and handles edge heights from 18–65 mm, thickness 0.5–3.0 mm. With a 1,200 W heater (8 min warm-up) and dual feed speeds (2 or 4 m/min), it produces strong, factory-quality joints on wood, PVC, or melamine panels.

-

Pros: Excellent for inside/outside curves and corners; quick-change EVA glue (no glue pot); 3-year factory warranty; precise glue flow and trims included (see Festool supplies); ideal for precision cabinetry.

-

Cons: Very expensive (Festool high-end); slower feed for large runs; requires Festool EVA glue cartridges; heavier and bulkier than some handhelds; extra cost for accessory table or trimmers.

Overall, the Conturo KA 65 delivers the best edge quality for finish carpentry, at a premium. Its system (hand bander + trimmers) lets you “create a perfect edge” without a stationary machine.

4.2. Virutex AG98F

The Virutex AG98F is a lightweight hot-air edgebander for pre-glued PVC/melamine/veneer tapes. It heats tape from below, so no glue pellets are needed. This makes setup very fast (under 1 min). It can apply pre-glued edging up to 50 mm wide with thickness up to 1 mm.

-

Pros: Very light (2.7 kg) and truly handheld; heats tape exactly at bond line for reliable adhesion; clamps ensure straight feed; quick to use on site; includes handy edge trimmer accessories; relatively low cost (tool-only price ≈$800).

-

Cons: Only works with pre-glued tapes – you cannot use ungummed wood edge or raw PVC without prep; maximum width 50 mm is limiting for thick laminates; .

For a budget shop needing occasional banding, the AG98F is a portable, no-frills solution. It excels on straight and curved pieces when pre-glued edgeband is used.

4.3. Grizzly G0825

The Grizzly G0825 is a true glue-pot portable edgebander, more akin to a mini-stationary machine. It can apply PVC or ABS tapes 3/8″ to 2½″ wide (10–63 mm) and thickness up to 1/8″.

-

Pros: Hot-melt glue gives very strong bonds; applies to straight, convex, concave, even inside corners; trim/router accessories yield professional edge finish; adjustable speed/temp means consistent application; one-year warranty; popular with professionals (Grizzly USA support).

-

Cons: Heavy (~42 lb/19 kg) – not truly handheld; bulky with table/trimmer; fairly expensive ($1,395 on sale); glue pellets required (sold separately); 4 min warm-up time; overkill for very small jobs.

The G0825 brings many stationary features into a portable package. It’s best for small shops doing frequent melamine or solid-surface edges on cabinets or furniture. The touchscreen control and glue flow mean professional speed and finish at a fraction of floor-model cost.

4.4. Co-Matic BR300

The Co-Matic BR300 claims to be the “world’s lightest, most compact” portable edgebander.

- Features: 855 W, glue pot 400 ml, temperature 120–200°C, speed 4 m/min, thickness 0.4–3 mm, width 10–65 mm, weight 8.7 kg.

- Pros: Adjustable handle, handles curved edges, material compatibility, continuous operation, portable/stationary use.

- Cons: Lacks digital controls, variable warm-up time.

4.5. Bestin Portable Edge Banding Machine D-260

The BESTIN D-260 is a high-end portable edgebander from BESTIN, geared toward larger furniture panels (the “260” implies a very wide edge capability). While official specs are scarce, it reportedly handles edges up to ~260 mm wide – far larger than most handheld machines – and supports 0.4–3 mm tape thickness.

- Features: 220V, heating 5–8 minutes, 1200 W, glue 1000 ml, stepless speed, straight/curve edges, weight 14 kg.

- Pros: Versatile, double-sided gluing, quick heating, large glue capacity, 12-hour continuous use.

- Cons: Manual belt breaking.

4.6. Bestin FB-50

The BESTIN FB-50 is a compact model optimized for narrow-to-medium edgebanding. It likely maxes out around 50 mm width (hence “FB-50”), working with 0.4–2 mm thick PVC/ABS or wood tapes. It appears to be a glue-pot bander on an aluminum frame, possibly with a small heating element and roller (similar to older vacuum banders). Its emphasis is on portability and ease of use.

- Features: 1000 W, heating 5–10 minutes, width 10–60 mm, glue 1000 ml, thickness 0.3–2 mm, weight 24 kg, handles various edges.

- Pros: Versatile, large glue pot, adjustable speed, compact.

- Cons: Limited speed (6 m/min), needs air source.

5. How to Maintain Your Portable Edge Bander?

5.1. Regular Cleaning and Lubrication

-

Clean the glue pot regularly to prevent buildup.

- Lubricate moving parts according to the manufacturer’s instructions to maintain smooth

operation.

5.2. Inspection for Wear and Tear

-

Regularly check for worn parts such as the feed rollers and the heating element.

- Replace any damaged components promptly to avoid further issues.

5.3. Proper Storage Practices

-

Store in a dry, dust-free environment.

- Keep the machine covered when not in use to prevent dust accumulation.

6. Common Mistakes to Avoid

-

Overheating the Glue Pot: Always monitor temperature settings.

- Incorrect Feed Speed Settings: Match the feed speed with the material and edge thickness.

- Neglecting Regular Maintenance: Follow the maintenance schedule to prevent malfunctions.

- Using the Wrong Adhesive for Specific Materials: Always check compatibility between

adhesive and material.

7. How to Maximize the Efficiency of Your Portable Edge Bander?

7.1. Tips for Faster Setup:

-

Prepare all materials and set up the machine before starting the edge banding process.

- Preheat the glue pot while preparing the edges to save time.

7.2. Optimizing Temperature Settings:

-

Adjust the temperature according to the material’s requirements to ensure optimal adhesion.

7.3. Best Practices for Edging Different Materials:

-

Use lower temperatures for thinner edges and higher temperatures for thicker materials.

- Ensure consistent pressure for even glue application.

7.1. Enhancing Precision with Proper Technique:

-

Maintain a steady hand and consistent speed when feeding material through the machine.

- Practice on scrap materials before working on the final product.

8. Safety Tips When Using a Portable Edge Bander

8.1. Protective Gear Recommendations

-

Always wear safety glasses and heat-resistant gloves.

- Use ear protection if the machine is loud.

8.2. Safe Handling and Operation

-

Never touch the glue pot or heating element while the machine is on.

- Keep hands away from the feed rollers during operation.

8.3. Emergency Procedures for Malfunctions

-

Turn off the machine immediately if you notice any unusual sounds or smells.

- Unplug the machine before attempting any repairs.

9. Portable Edge Bander Accessories

-

Additional glue pots for quick adhesive changes.

- Edge trimmers for a clean finish.

- Optional Add-Ons for Enhanced Performance: Extension tables for larger panels.

- Specialized rollers for different edge materials.

10. Conclusion

A portable edge bander is an invaluable tool for woodworkers making cabinets or interior decorations.

By understanding the key features, benefits, and maintenance requirements of portable edge banders, you can select the best model to suit your specific needs.

Whether you’re working in a compact workshop or on-site, a portable edge bander will ensure that your projects are completed perfectly.