In the realm of woodworking and manufacturing, CNC (Computer Numerical Control) router machines have become essential tools, offering precision, efficiency, and versatility for both hobbyists and industrial users.

However, understanding the total cost of ownership is crucial before making such an investment. This article provides a detailed breakdown of CNC Router Machine Cost, from initial purchase to ongoing expenses, ensuring you can make an informed decision.

By the end, you’ll have a clear picture of what it takes to own a CNC router and how it can benefit your business, with calls to action to explore options with a trusted supplier.

China has emerged as a global hub for CNC router manufacturing, providing options ranging from hobbyist desktop routers to large industrial panel routers. You can try buying a CNC router from China.

Featured Resource

Table of Contents

1. Understanding CNC Router Machines

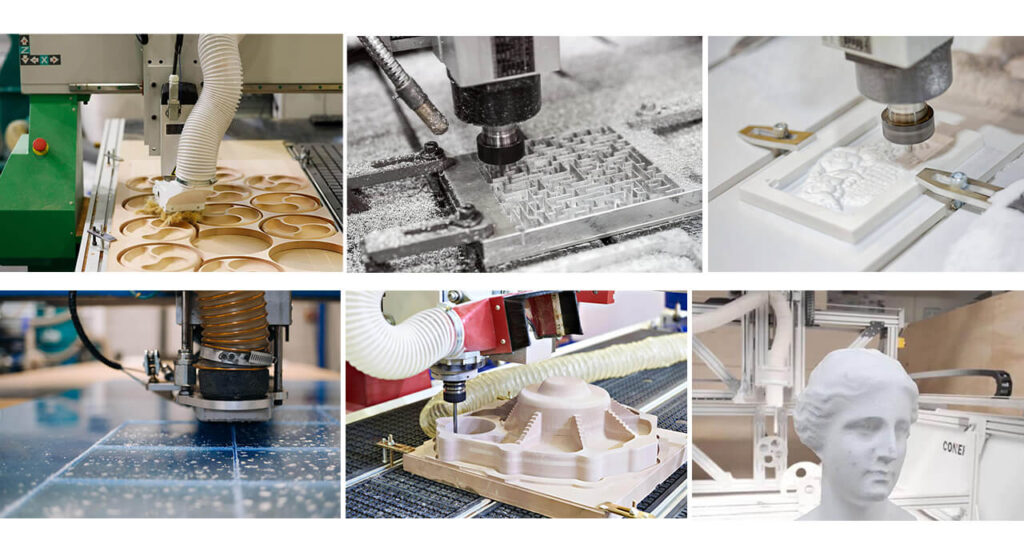

A CNC router is a computer-controlled cutting machine used for shaping materials like wood, metal, plastic, and composites.

It automates tasks such as cutting, carving, and engraving, making it ideal for intricate designs and high-volume production. The benefits include increased productivity, reduced labor costs, and the ability to handle complex projects, making it a valuable asset for small businesses and large manufacturers alike.

2. Initial Purchase Price

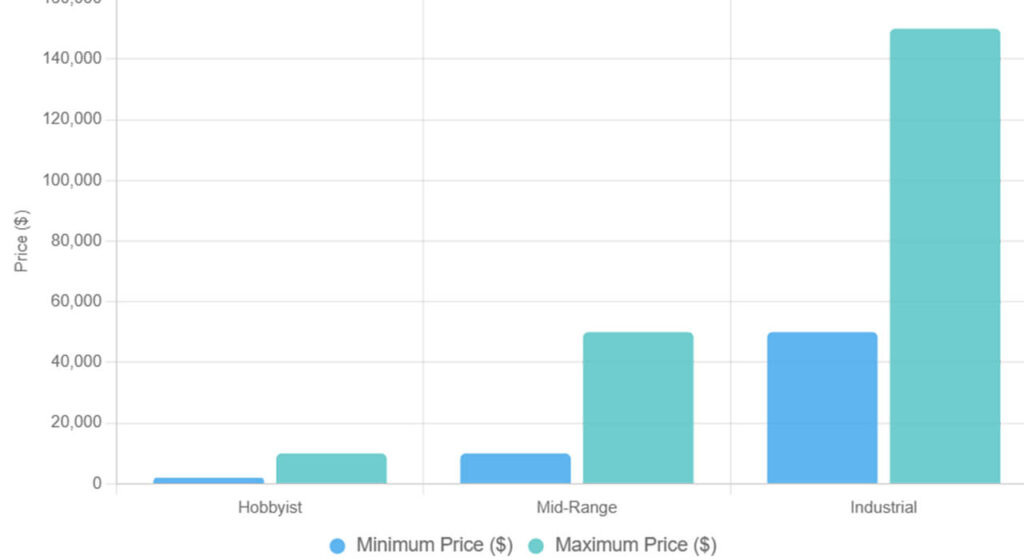

The initial purchase price is the most visible cost of owning a CNC router—and it varies widely based on your needs. Factors like machine size, spindle power, control system, and build quality all influence the price. Here’s a breakdown of the typical ranges:

- Hobbyist CNC Routers: Perfect for small projects or startups, these machines range from $2,000 to $10,000. They offer basic functionality but may lack advanced features.

- Mid-Range CNC Routers: Ideal for growing businesses, these models provide greater precision and speed, costing between $10,000 and $50,000.

- Industrial CNC Routers: Built for heavy-duty, large-scale production, these top-tier machines can exceed $150,000. Since ATC CNC router has many advantages, its price will be more expensive

At Bestin Company, we’ve tailored our CNC router lineup to suit every customer:

- Bestin HobbyCNC: Starting at $3,500, it’s an affordable entry point with reliable performance.

- Bestin ProCNC Series: Beginning at $12,000, this series offers enhanced capabilities for professional use.

- Bestin IndustrialCNC: Priced from $45,000, it’s designed for maximum durability and output.

To illustrate how prices vary, here’s a bar chart comparing the ranges across different CNC router types:

3. Additional Equipment and Accessories

Beyond the machine, several accessories are necessary for full functionality, each adding to the total cost:

- Router Bits: Essential for cutting and shaping, these can cost between $8 and $268 each, with monthly expenses around $80 to $160 depending on usage.

- Dust Collection System: Keeps the workspace clean and extends machine life, with prices ranging from $500 to $2,000.

- Automatic Tool Changers: Enhance efficiency by allowing automatic tool switching, adding approximately $1,500 to the cost.

- Rotary Attachments: For cylindrical workpieces, starting at $980, useful for projects like table legs or decorative items.

- Software: CAD/CAM software is crucial for design and operation. Costs range from free open-source options to $1,000–$10,000 for professional suites, with some machines including basic software.

These additional costs can significantly impact your budget, so it’s important to plan ahead and consider what accessories are essential for your specific needs.

4. Installation and Setup Costs: Getting Started

Purchasing your CNC router is just the beginning—getting it installed and operational adds to the investment. These costs depend on the machine’s size and complexity:

- Delivery Fees: Shipping a CNC router can cost $500 to $2,000, with larger machines requiring specialized transport that drives up expenses.

- Professional Installation: Smaller models might be DIY-friendly, but mid-range and industrial routers often need expert setup for calibration and safety. Expect to spend $500 to $2,000.

- Workspace Preparation: Your shop may need upgrades—think reinforced flooring, improved ventilation, or electrical enhancements—ranging from $1,000 to $5,000.

Skipping proper setup can lead to inefficiencies or damage, costing you more in the long run.

5. Training Expenses: Mastering the Machine

A CNC router’s potential is only as good as the team operating it. Training is a critical investment to ensure efficiency and avoid costly errors.

- Initial Training: Basic operator training typically costs $200 to $1,000 per person, depending on the machine’s features and the program’s depth.

- Advanced Training: To leverage complex designs or software updates, ongoing education might run $500 to $2,000 annually.

Well-trained staff can boost productivity and reduce waste, making this expense a stepping stone to profit.

6. Operational Costs

Once operational, ongoing costs include:

- Maintenance and Repairs: Routine tasks like lubrication, wear checks, and alignment are essential, costing several hundred dollars annually for supplies. Unexpected repairs can range from a few hundred to several thousand dollars.

- Consumables and Tooling: Cutting tools, such as end mills and router bits, need regular replacement, with costs ranging from $20 to $200 each. Lubricants and coolants also add to expenses, varying by usage intensity.

- Energy Consumption: Larger machines with powerful spindles consume more electricity, impacting utility bills. Estimate based on the machine’s power rating and daily operational hours, which can be significant for high-usage scenarios.

- Materials: While not a direct machine cost, the cost of wood, metal, or other materials processed by the router should be considered in overall budgeting.

These ongoing costs can vary based on usage, with intensive operations potentially adding thousands annually.

7. Software Costs

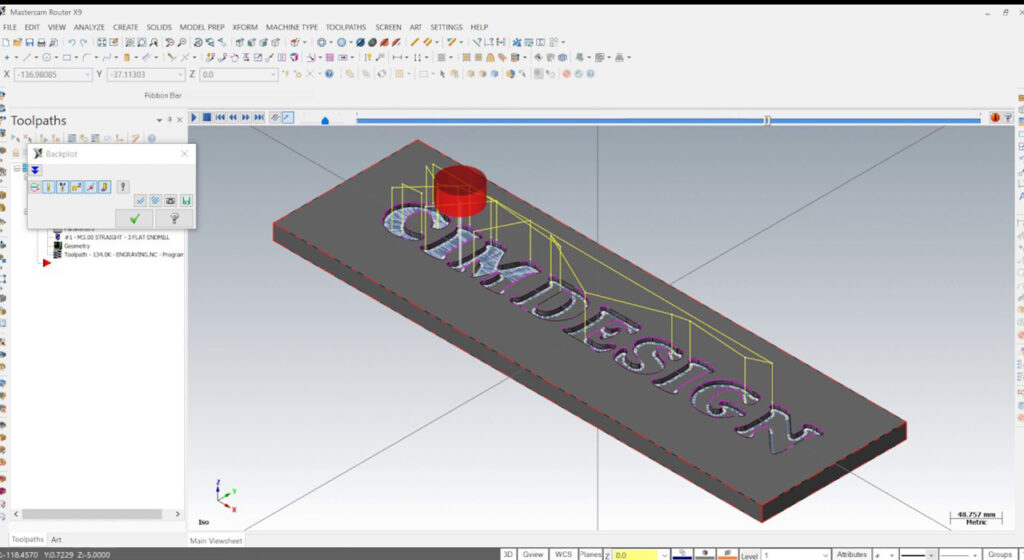

Software is a critical component for operating a CNC router, with two main types needed:

- CAD (Computer-Aided Design) Software: Used for creating designs, with options like AutoCAD, Fusion 360, and SketchUp. Prices range from free for hobbyist versions to subscription-based models for professionals.

- CAM (Computer-Aided Manufacturing) Software: Converts designs into machine-readable code, with examples like VCarve and Mastercam. Costs can be free for open-source options or several thousand dollars for advanced suites, with potential annual licensing fees.

Some machines come with proprietary software included, but for advanced features, additional purchases may be necessary, adding to the total cost.

8. Total Cost of Ownership

To grasp the full financial commitment, let’s estimate the total cost of ownership (TCO) for a mid-range CNC router over 5 years:

- Initial Purchase Price: $20,000

- Installation and Setup: $1,500

- Training: $1,000

- Operational Costs (5 Years): $10,000 ($2,000/year)

- Software: $3,000

- Hidden Costs: $2,000

Total Estimated TCO: $37,500

This figure varies based on usage, machine type, and maintenance habits, but it’s a solid starting point. The real question is: how does this investment pay off? Let’s explore the return on investment next.

9. Return on Investment (ROI): The Profit Potential

A CNC router’s costs are significant, but the benefits can far outweigh them. Here’s why it’s a worthwhile investment:

- Boosted Productivity: Automation speeds up production, with many users seeing 30% to 50% efficiency gains. More projects mean more revenue.

- Lower Labor Costs: By reducing manual work, you can save thousands annually on payroll.

- New Opportunities: Precision cutting opens doors to high-value projects like custom furniture or signage, increasing your profit margins.

Consider this example: A business spends $20,000 on a Bestin ProCNC and gains a 25% productivity boost, adding $10,000 in annual revenue. Within two years, the machine pays for itself, with profits growing thereafter.

Bestin Company’s reliable, high-performance CNC routers are built to deliver this kind of ROI. Contact us today to see how our machines can drive your business forward!

10. Conclusion: Invest with Confidence

Owning a CNC router machine involves multiple costs—purchase price, installation, training, and more—but the rewards are undeniable.

Increased efficiency, reduced labor, and expanded capabilities can transform your woodworking business and drive profit growth.

Don’t let the numbers intimidate you. With Bestin Company, you’re not just buying a machine—you’re gaining a partner dedicated to your success.

Our industry-leading CNC routers, expert support, and financing options make this investment accessible and profitable. Contact us today to discover how a Bestin CNC router can elevate your business. Take the first step toward precision, efficiency, and growth—reach out now!